Electric heaters are any electric-powered devices used to create heat. Electric heat generation takes place when electricity is converted into thermal energy. During this conversion, an electric charge is conveyed by electrons through a medium. Inside the medium, the electrons collide with atomic particles from an electric heating element, and vibrate. These vibrations manifest as heat. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

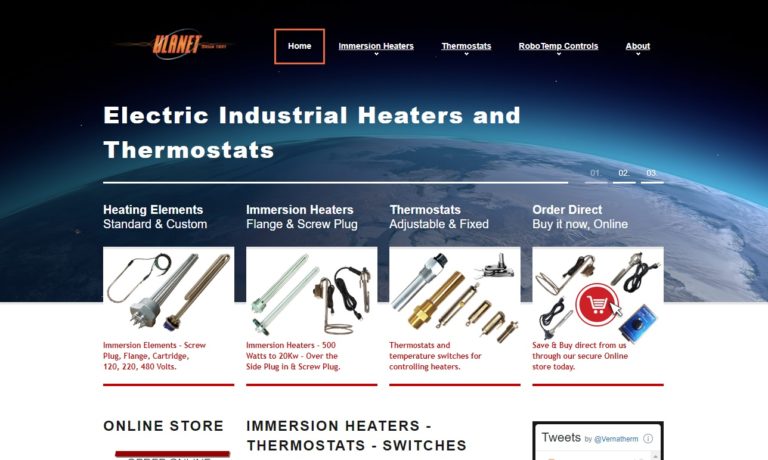

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

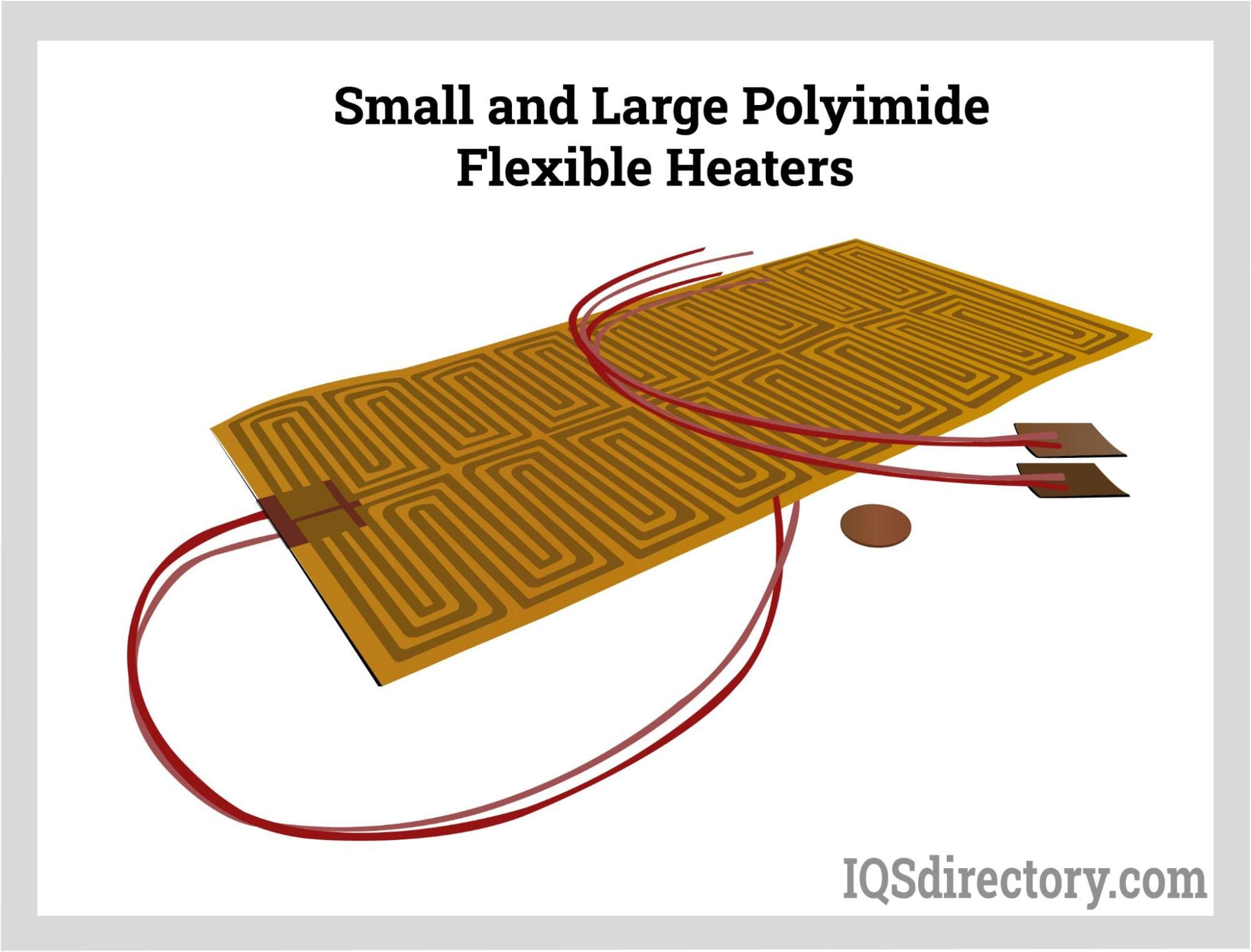

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

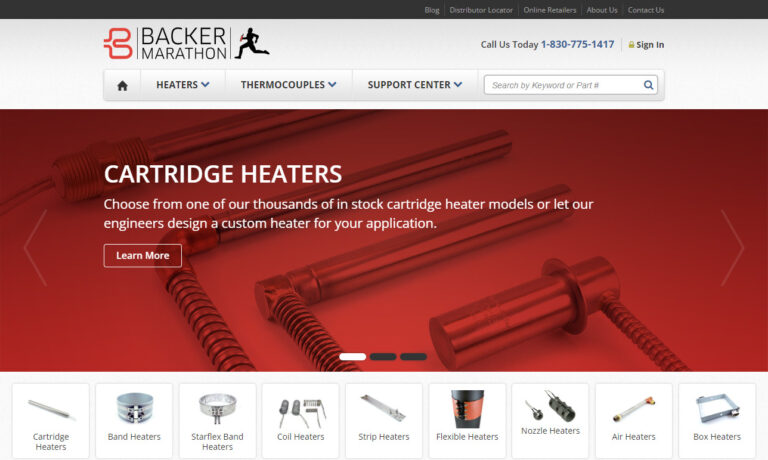

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Electric Heater Manufacturers

Electric Heater Applications

Electric heaters have widespread applications throughout many industries, where they provide heat for all sorts of reasons. For example, in industrial and manufacturing processes, they can provide heat to warm liquid tanks, help shape or melt material or radiate heat in the air to preserve a substance’s molten state. Likewise, in extrusion processes, electric heaters sometimes supplement natural friction to create and support material plasticization. Other processes that benefit from electric heaters include packaging, foam fabricating, metal fabricating, food processing and water treatment. They also provide heating for comfort to both residential and commercial buildings.

History of Electric Heaters

In the early 1890’s, the American company General Electric began producing the first heaters. These heaters relied on elongated glass bulbs, which had only been invented the decade before, as their heating element. They looked like table lamps. The earliest electric heaters work using bulbs, which were invented by Thomas Edison in 1880. While these heaters did provide some warmth, they were neither durable nor particularly strong. In addition, they were not terribly versatile. To remedy the situation, Albert Leroy Marsh fabricated the alloy chromel. Chromel, also known as nichrome, was the first alloy used as a heating element. Up to 300 times stronger than other alloys of the day, chromel can heat it up to 1400℃, and it resists corrosion. Heaters with chromel heating elements were able to create and disperse heat more efficiently than lightbulb heaters.

Meanwhile, over in the UK, based off of the bulb heater Hebert John Dowsing designed an all-electric cooking system. It featured a copper backing that allowed heat radiation to enter a room gradually. Debuting his invention in 1891, Dowsing is considered the father of domestic heating in the UK.

Another invention of the late 19th century was the electric water heater, developed by Norwegian mechanical engineer Edwin Ruud. His model featured automatic electric heating of stored water. Initially working for the Fuel and Gas Manufacturing Company in Pittsburgh, he eventually started his own company, the Ruud Manufacturing Company, in 1897. His water heater company is successful to this day.

In 1912, manufacturers began producing portable heaters. One of the earliest portable heating technology manufacturers was Charles Reginald Belling. The first patent for central heating was granted to Alice Parker in 1919. Hers was a gas heater. In 1935, another inventor added an electric fan and ductwork to this highly successful model, creating the first forced wall convection heater.

After World War II, radiant heating and the bar heater, also known as electric fire, were invented. Radiant heaters relied on bars of coiled water to work. When current passed through them, the wire would glow orange. Today, we still use radiant bar heaters. However, they are not exactly the same as the first ones. Particularly, they now have different safety standards. That’s because early bar heaters, which were typically portable, were easy to knock over. The result of this occurrence was often a fire and/or injury.

The 1960s saw the development of the storage heater, used in the home and in industrial settings to provide the same amount of heat while consuming less energy. The 70s and 80s experienced a heavier use of electric heat, as the systems were restructured and designed for greater capacities. Modern electric heating systems control heat production with smart technologies, like digital programming and remote controls. Electric heaters have not only made heating easier and more efficient, but have slowed pollution as they’ve decreased our dependence on wood and fossil fuels.

Electric Heater Design

Production Process

To make electric heaters, manufacturers must make or assemble heating elements, shielding or enclosures, and insulation materials. Heating elements generate heat. They may be simple coils or they may be comprised of elaborate shapes with advanced ceramic insulators to control heat qualities. The choice of what heating element design to construct is made by the manufacturer. The shielding (sheath) improves performance and extends operating life. Insulation retains and absorbs electrical energy so that it may be released as additional heat energy.

Materials

Almost all electric heaters feature a sheath made of ferrous or non-ferrous metal materials, like: nickel, stainless steel, aluminum or another conductive material. Manufacturers base materials on which one will best extend operating life and improve performance. Of all the insulation materials, such as minerals, mica or fiberglass, the most common types of insulation are made of or with ceramics.

Design Considerations and Customization

When helping you choose a system or designing a custom electric heating system for you, electric heater suppliers think about a number of different factors. First, they consider what you actually need to heat (A building? A room? Water?) Based on this, they sketch out a basic configuration. Then, they think about specific requirements like: operating temperature, operating efficiency, heater lifespan and permissible/safe watt densities. In addition, use your application specifications to calculate your system start-up power requirement, system maintenance power requirements and operating heat losses. They also consider the environment in which your heater will work. Finally, they take all of this information to decide what heating element material, electric heater type, size, quantity and control system will work best for you.

Types of Electric Heaters

There is an astonishing variety of heaters available on the market, including crossover styles, a variety that continues to grow daily. Other varieties include: band heaters, strip heaters, process heaters, cartridge heaters, radiating heaters, immersion heaters, circulation heaters, tubular heaters, air heaters, drum heaters and water heaters.

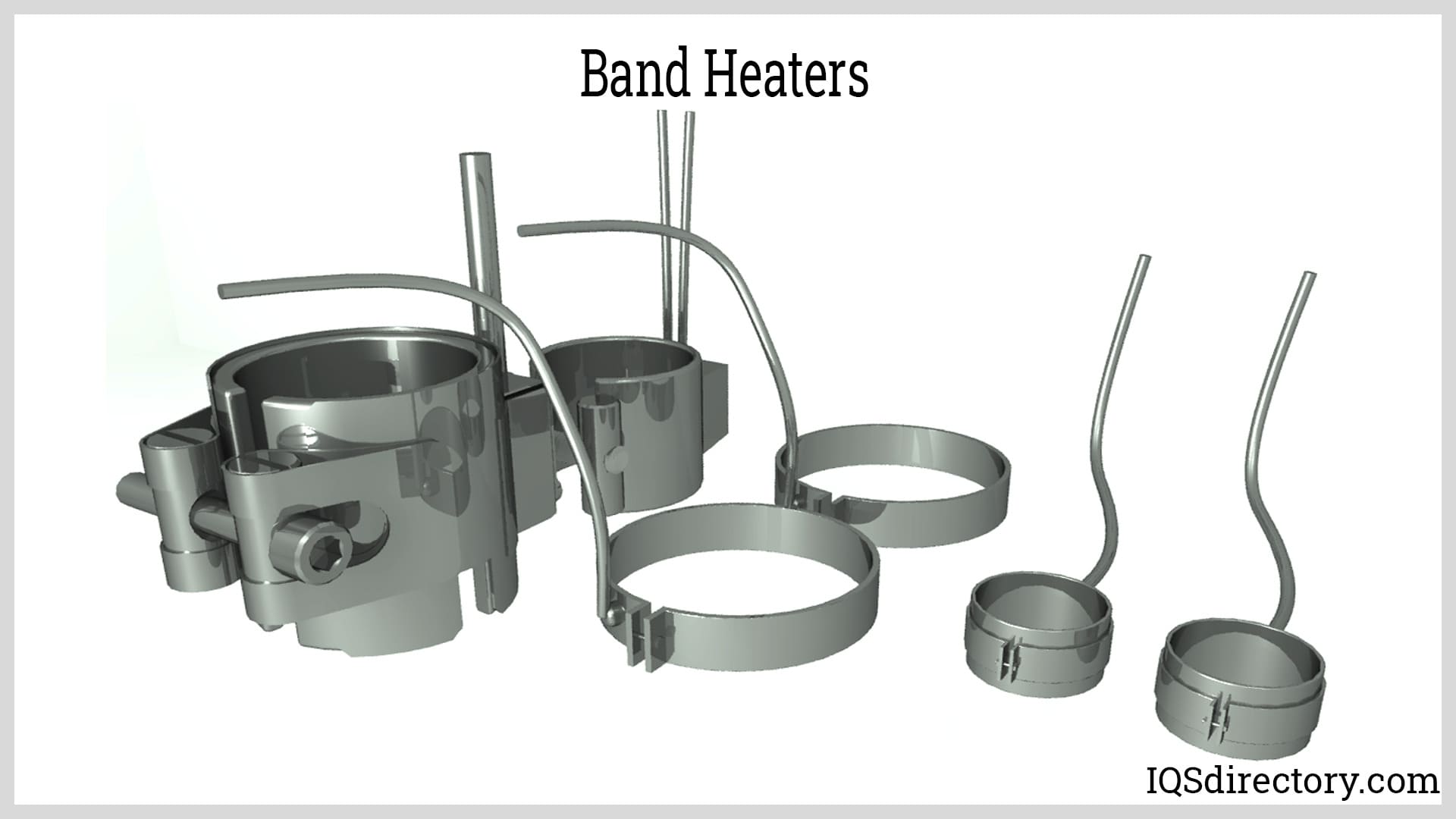

Band Heater

A band heater is a small electric heater that you can attach to nozzles, pipes and tubes for localized heating. It usually provides conductive heat, though it can also provide convection air heating. Band heaters can reach temperatures from around 300℉ to 1400℉. Also known as barrel heaters or knuckle heaters, band heaters are best for use in plastic and metal forming processes like extrusion. They can also be used to clear ice from troughs and gutters.

Strip Heater

Strip heaters are small heaters known for their rugged construction and low cost. To work, they can be clamped or bolted to equipment to directly provide heat. They can also heat small spaces inside enclosures. Strip heaters are typically straight and flat like a ruler, but often also feature fins, which offer fuller heat radiation into the air. Manufacturers can also produce circular strip heaters for use around cylindrical objects like tubing. Most often, they’re used for thawing, baking, platens, moisture protection, drying, melting, extrusion and air heating. Strip heaters and band heaters would be exactly alike if not for the fact that band heaters are usually slightly smaller and more flexible.

Process Heater

Process heaters are electric heaters used to heat treat, surface treat, shape and generally process raw materials.

Cartridge Heater

Cartridge heaters are small and cylindrical. They are designed this way so that they can be inserted into small holes drilled into metal parts and materials, where they provide internal heating. The heat they provide may be localized or it may radiate throughout the whole interior of that into which they are inserted. Typically, cartridge heaters are used in manufacturing processes like: extrusion, thermoforming, mold forming, plastic forming, rubber forming, labeling, die cutting, sealing, hot stamping, fluid heating and printing. You can find them inside of machinery like semiconductors, platens, hot plates and shrink wrap machines.

Radiating Heater

Radiating, or radiant, heaters work using the principles of radiant heat to radiate heat energy. They are straightforward and heat anything within their range.

Oil-filled radiant heaters use a combination of radiant heating and thermal convection to heat the surrounding air. The electricity heats the oil inside the heater fins; this then heats the cool air in the room. The oil has a high heating capacity; that is why it retains heat for long periods. Because of this, the temperature of the heater fins is sustained even though the heater is switched off.

Immersion Heater

Immersion heaters are a type of radiant heater. They heat liquids and some solids when they are immersed into them. Like cartridge heaters, they heat the space around them. Immersion heaters are safe and efficient tools for heating large volumes of liquids.

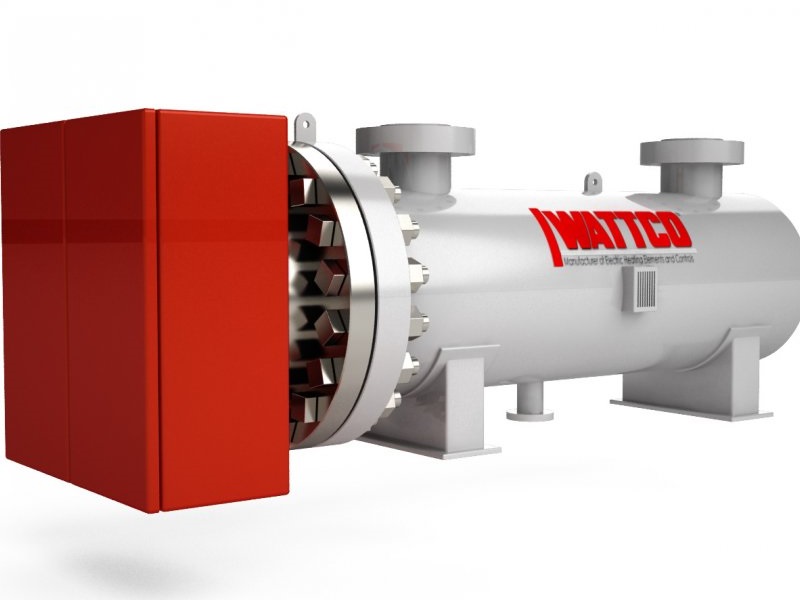

Circulation Heater

Circulation heaters, as their name implies, are electric heaters that heat the liquid or gas that circulates within an enclosed space.

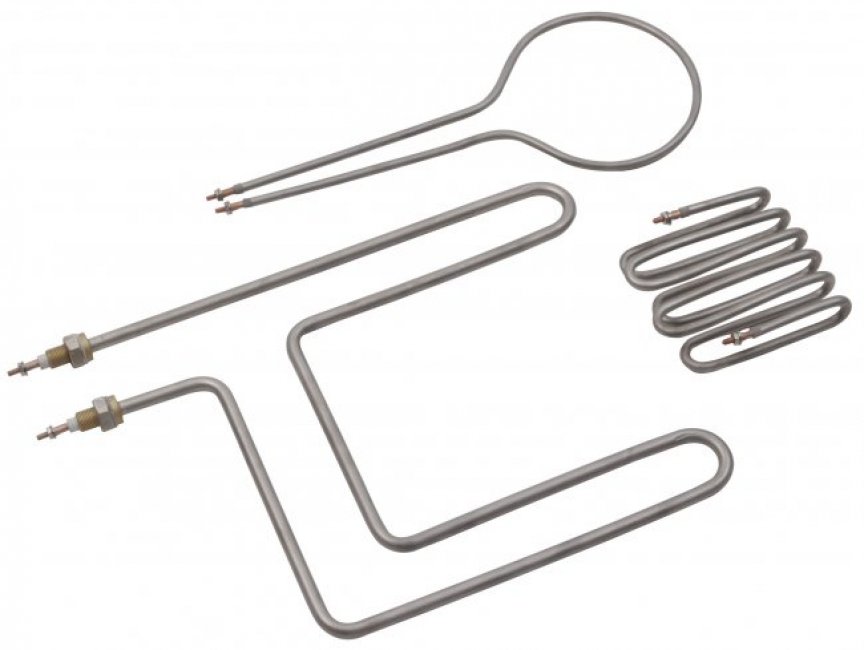

Tubular Heater

Tubular heaters are named after their tubular shape. They consist of a coil heating element, a heating element binder in which the coil is encased and magnesium oxide powder, which surrounds the binder. They can be installed or mounted on a wide variety of items and systems. They conduct heat via radiation, convection or conduction.

Air Heater

Air heaters heat air in residential, commercial and industrial settings alike. They may do so within a closed space, like space heaters do, or they may heat large spaces as part of a larger fan system. On top of that, they can be used to heat air for manufacturing and packaging processes, like shrink wrapping. When used to pass air through ducts, they’re also known duct heaters. They work via gravitational or forced air methods.

Drum Heater

Drum heaters are industrial heaters used specifically to heat industrial drums. The drums they heat usually hold water, chemical or food products that need to maintain a certain temperature during storage and/or shipment.

Water Heater

Water heaters, just as you’d expect, are used to heat water. There are several types of water heating, including: storage water tanks, tankless heaters, solar water heaters, geothermal heating, gravity fed water heating, point-of-use heating and centralized heating.

Ceramic Heaters

Typically, a ceramic heater uses convective heat transfer to heat the surrounding air. It is composed of a ceramic heating element, aluminum fins, and a fan to heat the surroundings rapidly and efficiently. While the aluminum fins heated by electricity transfer heat to the ceramic heating element, cool air is drawn over the ceramic heating element and other metal parts. Consequently, a fan blows the warm air into the room; this helps to heat the entire space quickly. The high thermal conductivity of the ceramic heating element allows the quick dissipation of heat, causing its temperature to ramp up at a faster rate.

Electric Heater Advantages

Among the many advantages of electric heaters are: versatility, environmental friendliness, energy efficiency and safety and reliability.

Versatility

First, electric heaters offer great versatility. They can be used for one small application, one large application or multiple applications. You can adjust coils by shape or size as an application calls for it and you have many options for heating different mediums (water, oil, air, etc.).

Environmental Friendliness

Next, electric heaters are far better for the environment than traditional heating methods, like petroleum, natural gas, coal or wood heating. Those traditional processes create pollution in the form of CO2 emissions, smog, fumes, smoke, vapor, chemicals and harmful gases. Electric heaters produce none of those pollutants. Electric heaters make the air cleaner for you, cleaner for your workers or family and friends, and cleaner the entire planet. That’s something we can get behind!

Energy Efficiency

Not only are electric heaters better for health and air quality, but they’re also more energy efficient than their traditional counterparts. All of the energy that electricity uses is converted directly into heat. This contrasts with fuel-based heaters, which waste energy through flue. This level of energy efficiency is good for the environment, and also presents significant energy and operating cost savings for you.

Safety and Reliability

Because electric heaters do not burn fuel, they are inherently much safer than their older counterparts. They are not subject to the risks of explosions, fires and monoxide poisoning. In addition, they do not present the risk of leakage. Finally, because they do not have moving parts to wear out or break down, they are far more reliable. On average, electric heaters last for at least 15 years.

Electric Heater Accessories

Possible accessories for your electric heater include: a thermostat, a thermocouple, gaskets, seals, baffles and remote temperature controls. We discuss these accessories in greater detail below.

Thermostats

Thermostats are essential accessories for electric heaters as they enable precise temperature control. A thermostat measures the ambient temperature and signals the heater to turn on or off accordingly. This ensures that the desired temperature is maintained and prevents overheating. Programmable thermostats offer additional benefits by allowing users to schedule temperature changes throughout the day, optimizing energy consumption and comfort.

Thermocouples

Thermocouples are safety devices commonly found in gas-powered heaters. They can also be used as accessories for electric heaters to provide an additional layer of protection. A thermocouple detects the pilot flame and ensures that the gas supply is shut off if the flame goes out. By installing a thermocouple in an electric heater, it can detect any malfunction or loss of power and automatically shut off the device, preventing potential hazards.

Gaskets and seals

Gaskets and seals are accessories used to create airtight seals between different components of an electric heater. They prevent air leakage and improve overall heating efficiency. Gaskets and seals are particularly important in electric heaters that rely on convection or forced-air systems to distribute heat. By ensuring that hot air is effectively contained and directed, these accessories maximize the heater’s performance and minimize heat loss.

Baffles

Baffles are accessories commonly used in electric heaters with a radiant heating element or heat exchange system. They help direct the flow of heat and improve its distribution within the heater. Baffles can be strategically placed to optimize heat transfer, ensuring that more heat is emitted towards the desired area. By enhancing the directional control of heat, baffles improve the overall effectiveness of electric heaters, providing more targeted and efficient heating.

Temperature Controls

Temperature controls, such as thermostats, knobs, or switches, are accessories that allow users to adjust and regulate the temperature output of an electric heater. They provide users with the flexibility to customize the level of heat according to their preferences and needs. Temperature controls are especially beneficial in situations where maintaining a specific temperature is important, such as in a greenhouse or industrial setting. These accessories offer convenience and adaptability, allowing users to optimize comfort and energy usage.

These accessories – thermostats, thermocouples, gaskets, seals, baffles, and temperature controls – contribute to the functionality, safety, and efficiency of electric heaters. By utilizing these accessories, users can enhance the performance of their heaters, achieve precise temperature control, improve heat distribution, and ensure the safety of their heating systems.

Electric Heater Installation

Electric heating is very easy to install. It simply requires a connection to the electrical circuit, so it can frequently be installed in a short span of time. As the heaters can work as stand-alone units or as a system, it is easy and cheap to add heaters to a system at any time, as budgets permit.

Proper Care of Electric Heaters

Cleaning and Maintenance

The biggest threat to an electric heater’s health is contamination, followed by excessive temperature cycling. To keep your heater happy, check on it regularly to make sure that it free of contamination, and also keep a log of temperature cycling, so that you don’t overdo it. Also avoid excessive movement.

Optimizing Performance

To optimize your heater performance, make sure that you are working with the best sheath material, maximum sheath temperature and watt density for the job. Compatibility is key.

Electric Heater Standards

Depending on the type of heater you plan to purchase, there are different federal/international/industry standards to which your system will have to adhere. For example, residential water heaters in the USA must meet the efficiency standards of the Department of Energy. The standards specific for water heaters vary by heater capacity. Likewise, heaters used in the USA must adhere to EPA emissions regulations. Standards can also vary by state. Other standard code certifications that you may want to look into for your heater include those put out by ANSI, the NFPA and ANSI/NFPA combined (National Electric Code, ANSI/NFPA 70). For more information, reach out to your local government and/or industry experts.

Things to Consider Regarding Electric Heaters

A sufficiently warm space makes for a comfortable and pleasant work environment amidst freezing weather. In areas like Canada, where temperatures can drop below freezing for weeks or even months, installing several layers of building insulation to contain the heat generated by a central heating system can ease discomfort but often won’t be enough. The addition of electric heaters in a particular room can improve comfort without cranking up utility bills. Modern electric heaters are lightweight and portable, making them suitable for any location. Electric heaters have heating elements that heat confined spaces. The heating elements used vary from one heater to another; their construction material, size, shape, and configuration significantly affect the heat transfer efficiency.

As electric heaters can be flexible and are made for use in a confined area, they consume less energy, making them a cost-effective heating solution. However, purchasing an electric heater is not as simple as it sounds. Various factors must be considered to determine the electric heater appropriate for your needs.

Determine the Heat Requirement

Before the purchase of an electric heater takes place, heating needs should be assessed. Heat requirement depends on the size of the room the electric heater will be used in. As a rule of thumb, around 10 watts of heating power is required for every square foot of floor area. Using an electric heater with a power rating above the intended heating power for the approximate area of your space will increase utility bills. An electric heater that’s too large for a space will consume more energy than a properly sized electric heater operating for the same duration of time. Prolonged operation of a small electric heater to supply the heating for a big room will also increase energy consumption.

Look for Features of an Energy-Efficient Electric Heater

Here are the criteria you should keep in mind when buying an electric heater for space heating to maximize utility cost savings:

High Heat Transfer Rate and High Heat Capacity

Electric heaters are classified based on the heating element used. Ceramic heaters, infrared heaters, and oil-filled radiant heaters are the known energy-efficient types of electric heaters.

Programmable Thermostat and Timer

A programmable thermostat allows for greater temperature control of the room. With the programmable thermostat, changing room temperature at any time of the day is possible. Once the preset temperature is reached, the unit will automatically turn on and off to keep the heat at a comfortable level. On the other hand, a programmable timer enables heater automation according to time. The heater automatically switches off after the time is up. Both programmable thermostats and timers not only help conserve energy, but also provide a layer of safety.

Multiple Heat Settings

Some models of electric heaters have multiple heat settings instead of a programmable thermostat. Multiple heat settings allow a heater to remain on a low setting to prevent energy waste when the room is properly heated. This feature will also help prevent spikes in utility bills.

Calculate Energy Costs

To further assess the cost-effectiveness of the electric heater you are planning to purchase, calculate the total energy costs associated with its use. First, determine the cost of electricity; it is usually expressed in price per kilowatt-hour and can be found on the electricity bill. Second, determine how many hours the heater will be operating. These determinations, combined with the power rating of the electric heater you plan to use, will allow the calculation of energy costs with the use of an electric heater.

The overall efficiency of the electric heater depends greatly on the design and construction of the heater and how it is used in conjunction with other heating systems. Again, electric heaters are most beneficial if they are used to heat a specific area and act as a supplemental heat source to a central heating system.

Choosing the Proper Electric Heater Provider

To get the most out of an electric heater, consider your application requirements, which will determine the material make-up and the power and temperature capacity you want. Different heaters respond differently to the environment you place them in or the tasks you give them. For safety and success, communicate your application intentions and requirements clearly with your service provider. It’s also important that you connect with a quality service provider, or all your efforts will be moot. Find the right provider for you by scrolling up towards the top of this page and perusing the many electric heater manufacturers and suppliers that we have listed there. All of those with whom we work are experienced and trustworthy. Pick out a few, perhaps three or four, in whom you are most interested, and then reach out to them individually with your questions and specifications. Compare and contrast not only the facts of the conversations, but the tones. It’s important that you choose a manufacturer that can not only deliver the bottom line, but that is also willing to work hard to make sure you’re satisfied. Once you’ve determined which company that is, get started on your project.

Check out our Electric Transformers website

Check out our Power Cords website

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services