Drum heaters come in various shapes and sizes, but they always serve the same purpose: to raise the temperature of liquids housed in standardized metal drums. These gadgets can be classified into a few different groups. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

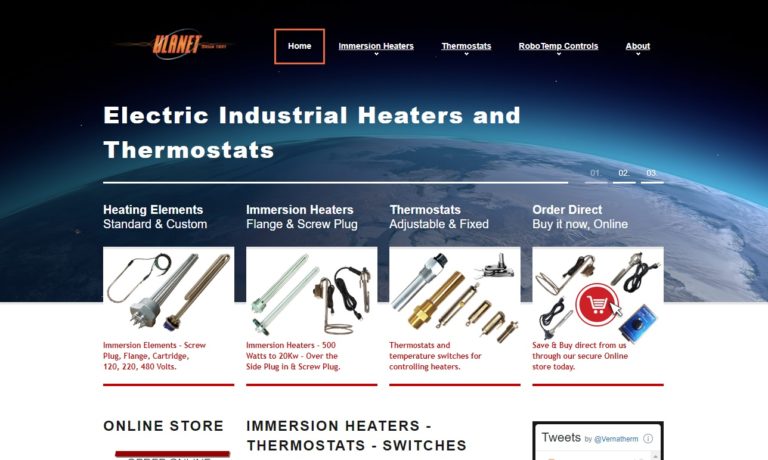

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

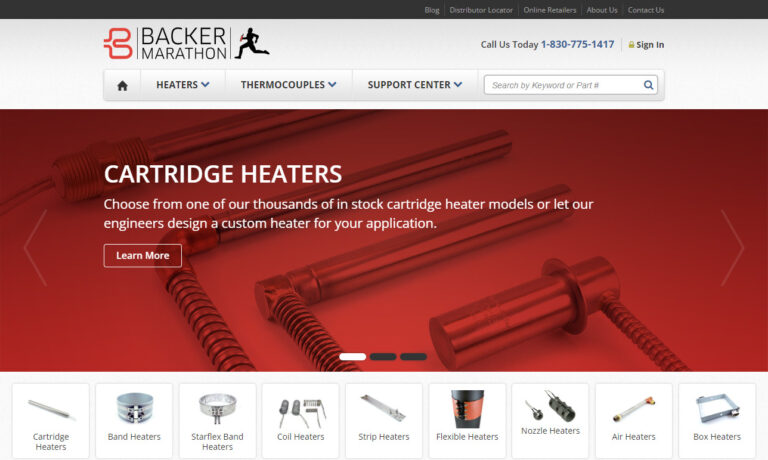

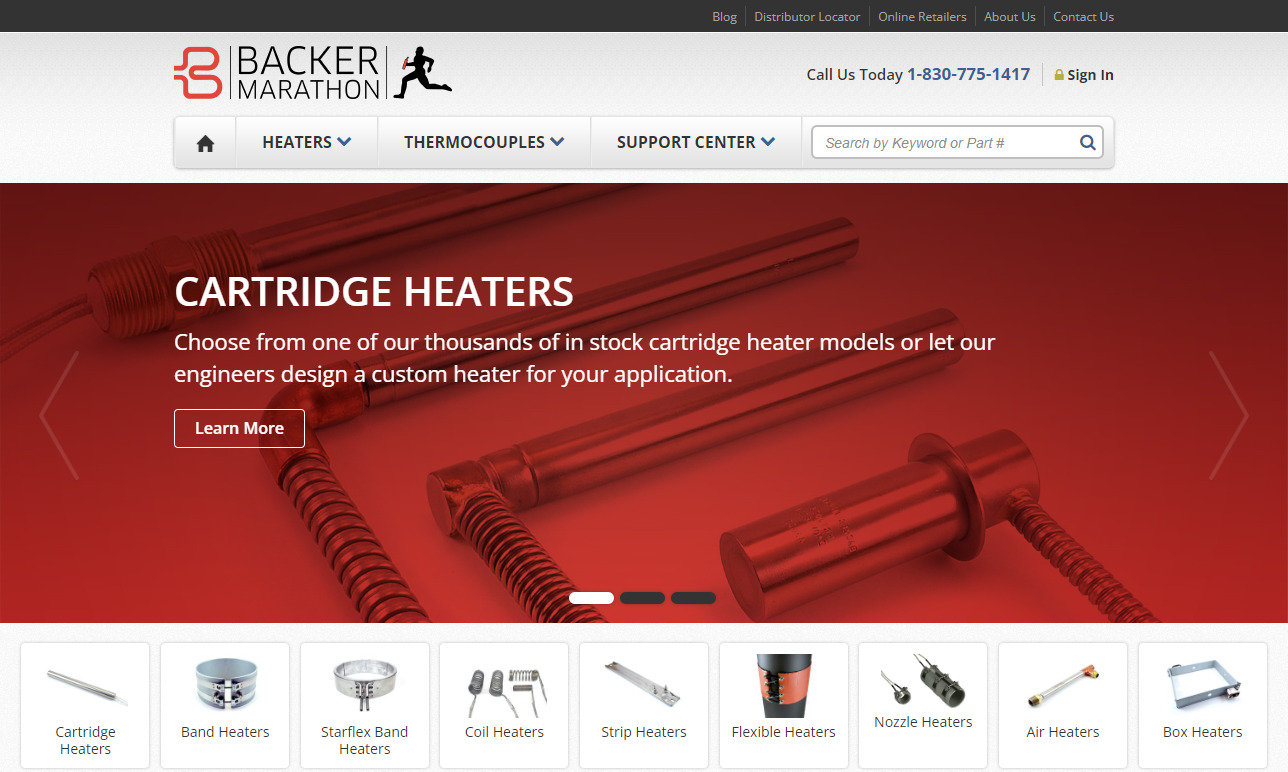

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

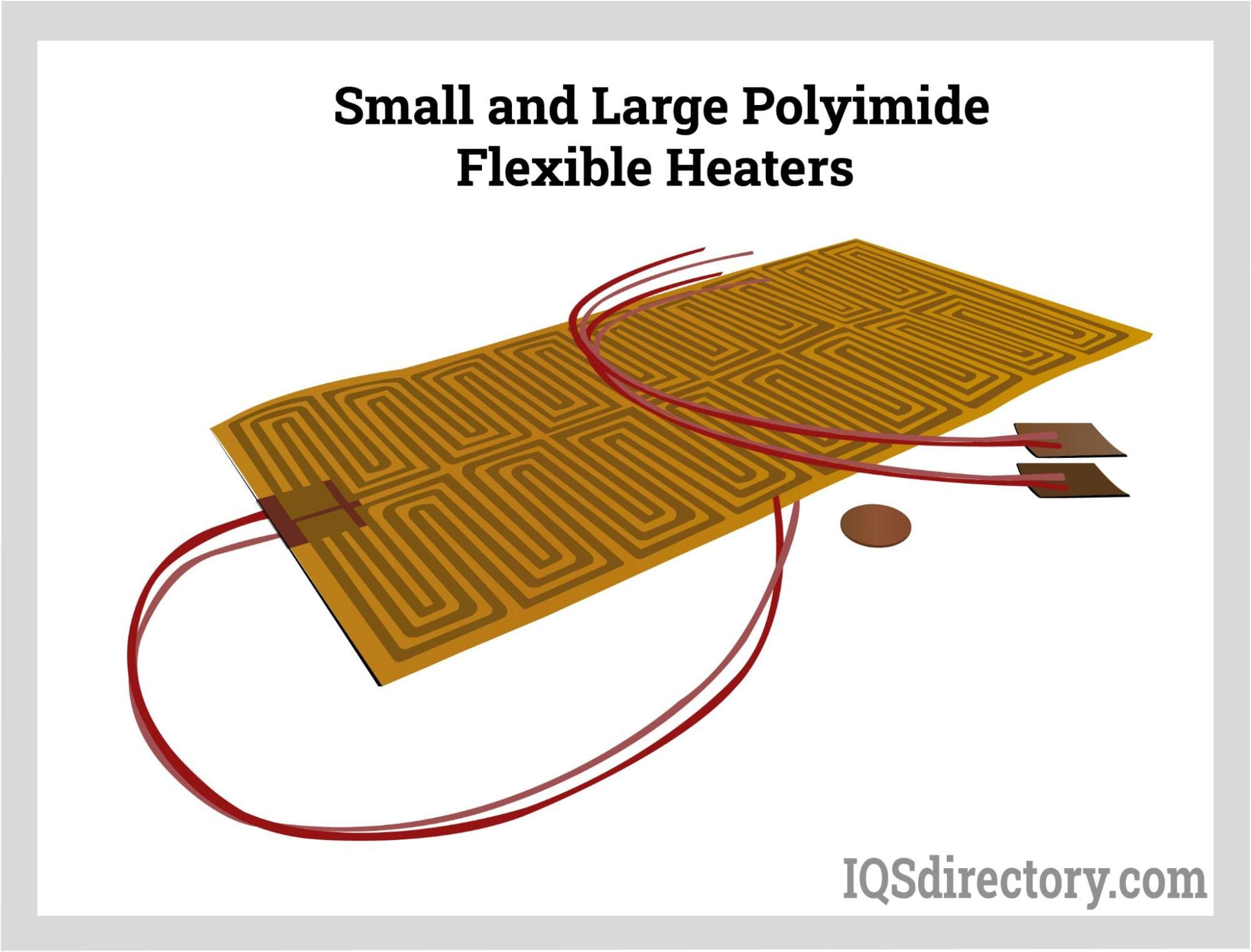

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Drum Heater Manufacturers

Depending on the model, a drum heater may warm many containers or simply one at a time. Drum warmers are available in various designs due to the multiple sizes available for drums. Some drum warmers reduce viscosity to make pouring or mixing easier, while others are merely designed to keep liquid from freezing.

Drum ovens are often known as the biggest drum heaters. On a pallet, a mobile version can carry a single drum or approximately four barrels, while massive, heated room-sized systems can commonly store several dozen drums. These heating chambers can warm up many barrels and keep them at a consistent temperature for long periods, but they are often expensive and energy-intensive. More efficient are transportable drum heater ovens and machines that only warm one barrel at a time.

Materials Used in Drum Heaters

- A drum heater's heating element is PTFE-coated and sandwiched between two double layers of siliconized fiberglass. The multilayer insulation ensures a high level of electrical safety.

- The siliconized fiberglass sheets are vulcanized and bonded under heat and pressure to make a material that can sustain harsh industrial use and is very flexible, resilient, and durable.

- A tension spring provides optimal contact with the barrel, rapid installation, and removal.

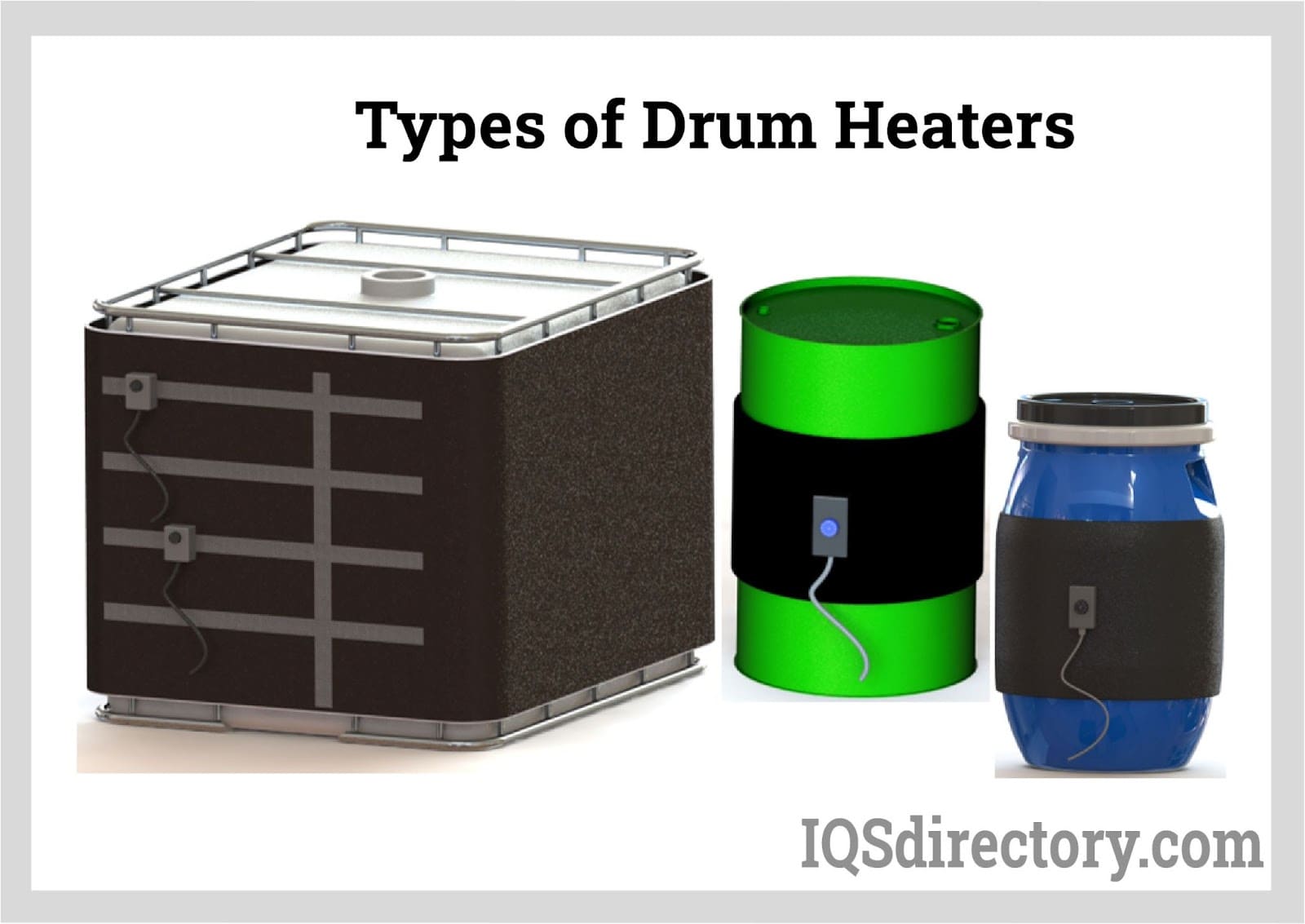

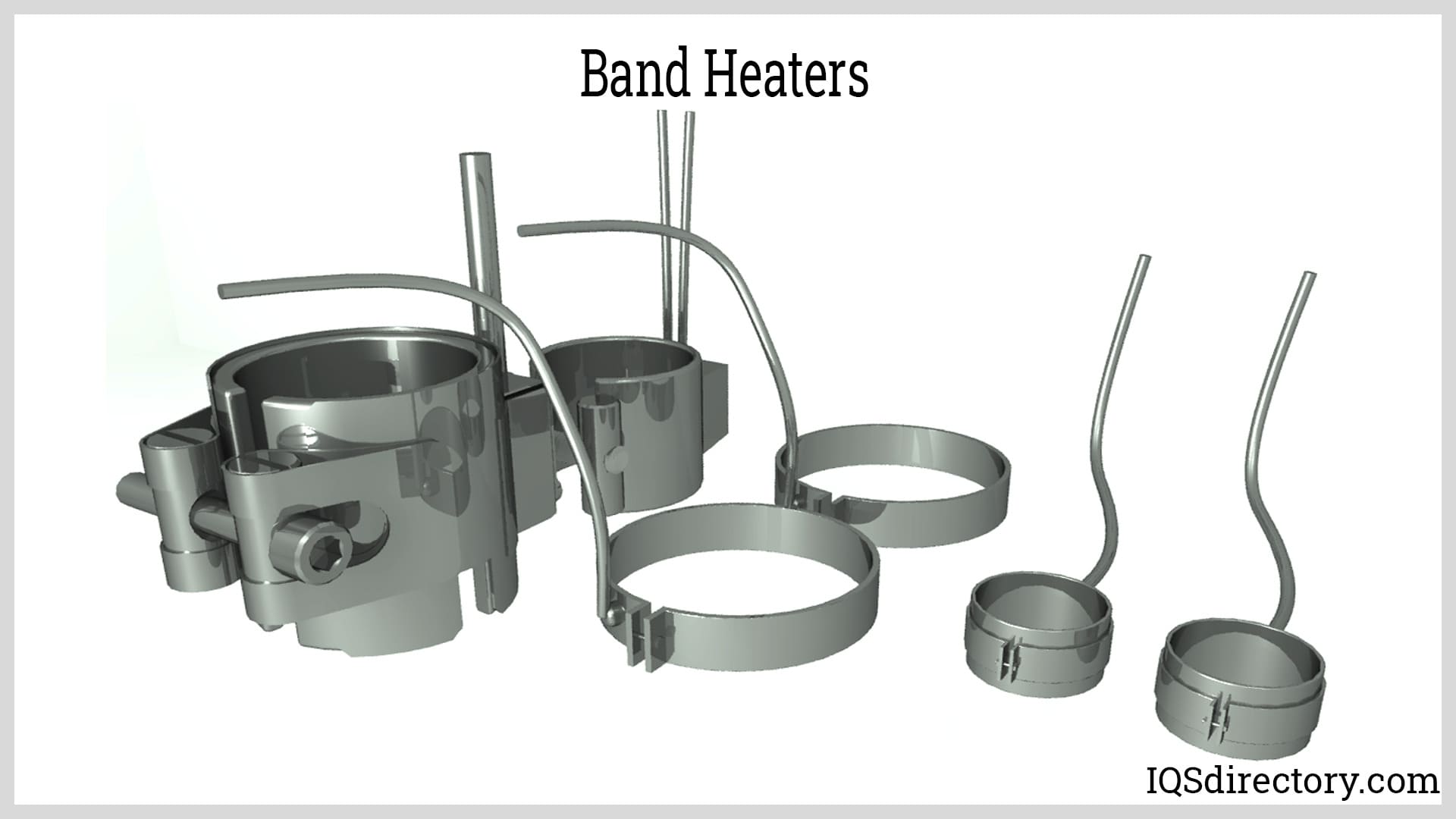

Types of Drum Heaters

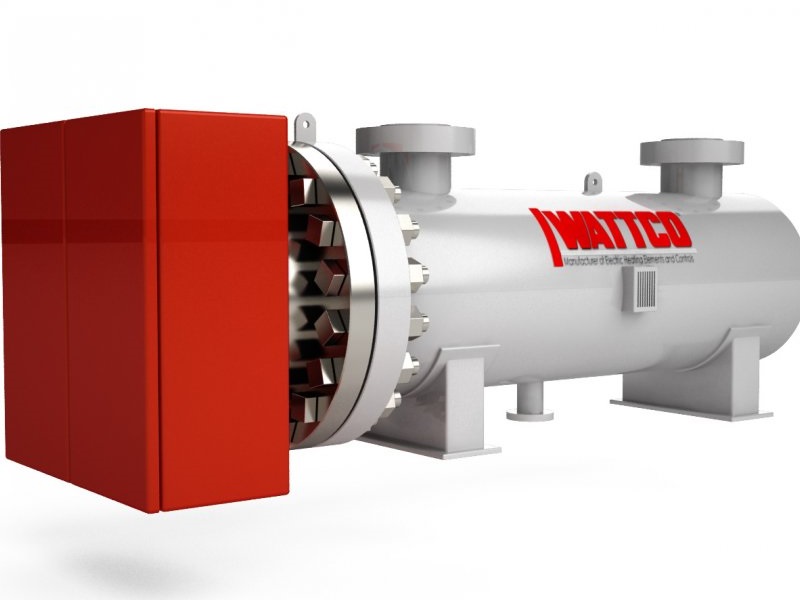

Cabinet Heaters

These can heat drums or varying-sized containers. They are usually equipped with a fan to improve air circulation and may be loaded and unloaded using a forklift.

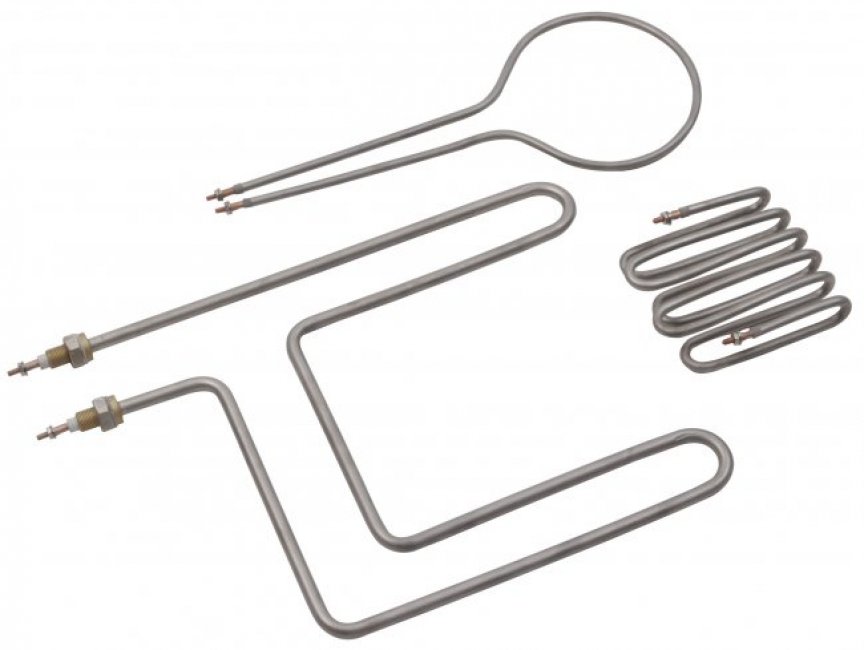

Insertion Heaters

They have heating components that fit into conventional bung apertures on the top of a drum. Because the heating element is submerged in the heated media, the sheath materials and watt densities must be chosen according to the kind of fluids to be heated.

Tunnel Drum Heaters

Tunnel drum heaters are heated with a conveyor-fed oven. They can be incorporated into automated drum handling systems and support a first-in, first-out product flow.

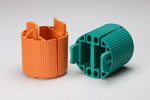

Wrap-around Heaters

Flexible heating components are built into a jacket or band clamped or fastened to the drum.

Construction of Drum Heaters

- On the one-piece type, the drum heater has a spring-loaded handle and a snap-action bi-metal temperature controller (220 °F or 104.4 °C).

- The drum heater's two-piece structure includes a latch and trunnion fastener, as well as a bulb and capillary thermostat (250 °F or 121.1 °C).

- They can be tied around, placed inside, or heated together with the contents of the container.

- All drum heaters are thick gauge sheet steel with a double skin design that houses the inner surface's electric heating components.

- Reinforced thermal insulation is installed on the heating components to prevent heat loss through the exterior wall.

Working of Drum Heaters

- A thin silicone coating is applied to the steel drum heating band.

- These bands act as insulators and may be placed up to three times to aid heating, contributing to keeping things heated and above the melting point.

- For these heaters to perform correctly, the drum must be completely sealed.

Benefits of Drum Heaters

- Because of its optimum balance of power, thermal insulation, and temperature control, the drum heater is meant to be energy efficient.

- The ability to manage the temperature of the drum's contents allows for quick heating of liquid to the required temperature, facilitating removal and maximizing the use of the liquefied product.

- Drum warmers keep the contents of drums warm and secure, preventing frost damage and distortion.

- They ensure viscosity control, freeze prevention, temperature maintenance, and solids melting by providing optimal and consistent heating to drums.

- Heater burnout is not a problem since energy efficiency is maintained.

- Drum heaters are simple to use and require minimal user effort.

Applications of Drum Heaters

- Because certain oils, for example, thicken at lower temperatures, induction heaters can be used to lower the product's viscosity, making it simpler to pump or mix.

- Materials that crystallize at cooler temperatures, such as honey, can be kept at warmer temperatures to avoid this.

- Drum induction warmers are frequently used to store goods that freeze in cold settings, such as paint.

- These devices can heat barrels to maintain viscosity, liquidity, and fluidity.

- In some cases, heat may be used to modify the molecular characteristics of the materials housed within a drum.

Choosing the Right Drum Heater Supplier

For the most beneficial outcome when purchasing drum heaters from a drum heater supplier, it is important to compare several suppliers using our directory of drum heater companies. Each drum heater supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly contact them for more information or request a quote. Review each drum heater business website using our patented website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services