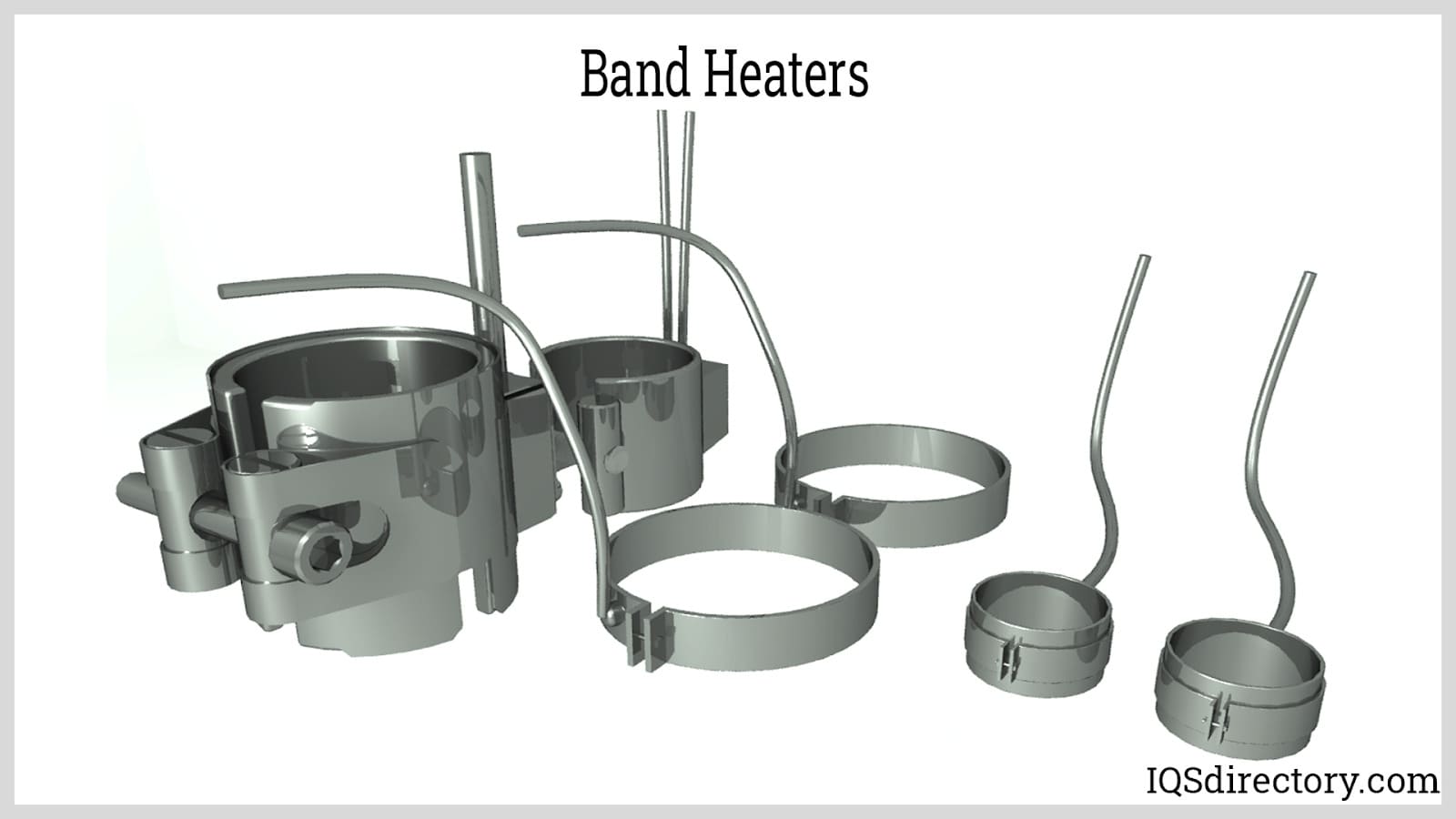

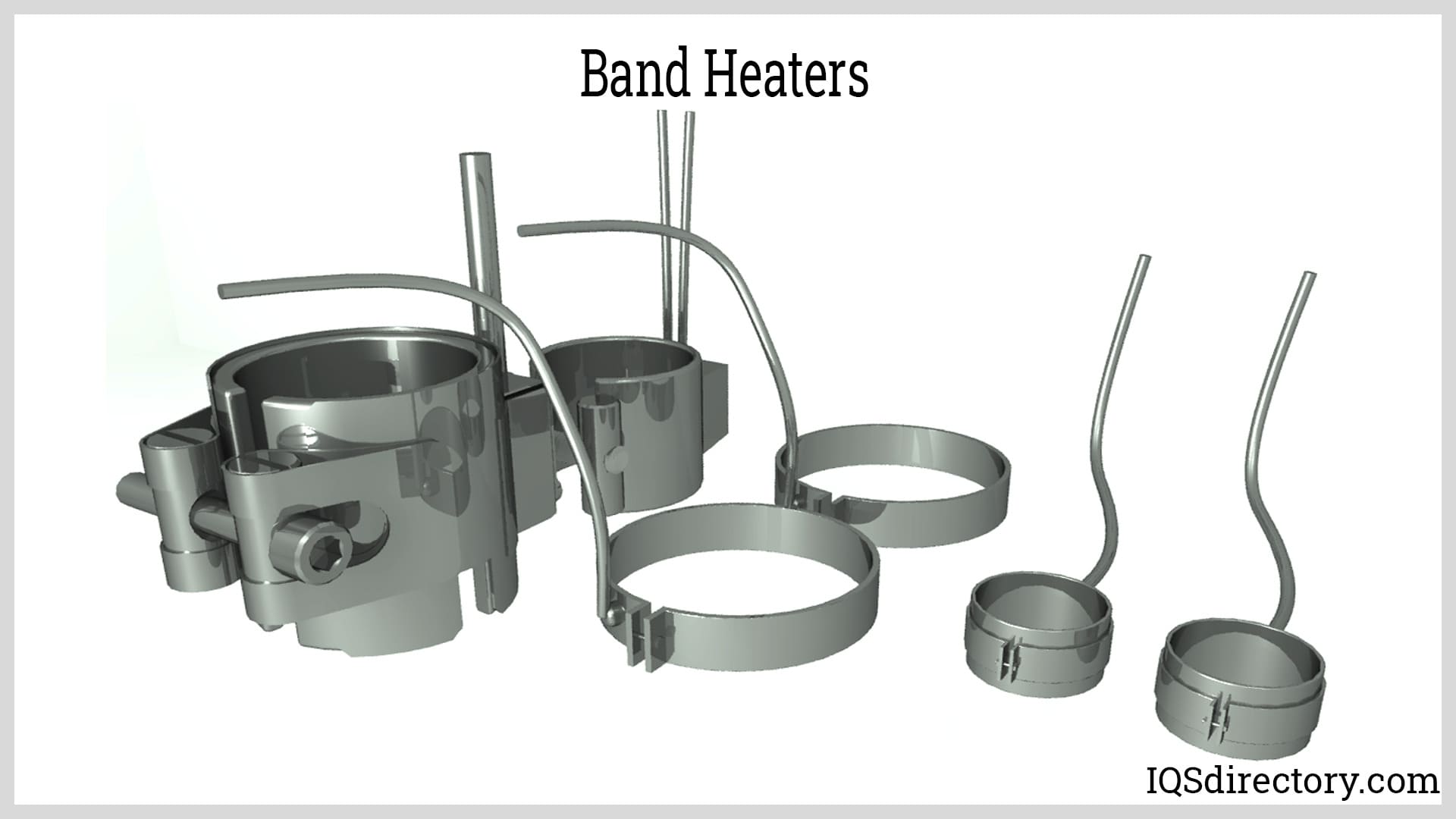

Band heaters are ring-shaped heating appliances that clamp over a cylindrical element. The conductive approach is used to transmit heat from band heaters. Usually, band heaters wrap around a cylindrical element’s outside diameter and heat it from the outside. However, some devices are designed to clamp around a pipe’s inner diameter. To decrease heat loss to the environment, band heaters are usually supplied with ceramic or mineral insulation. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

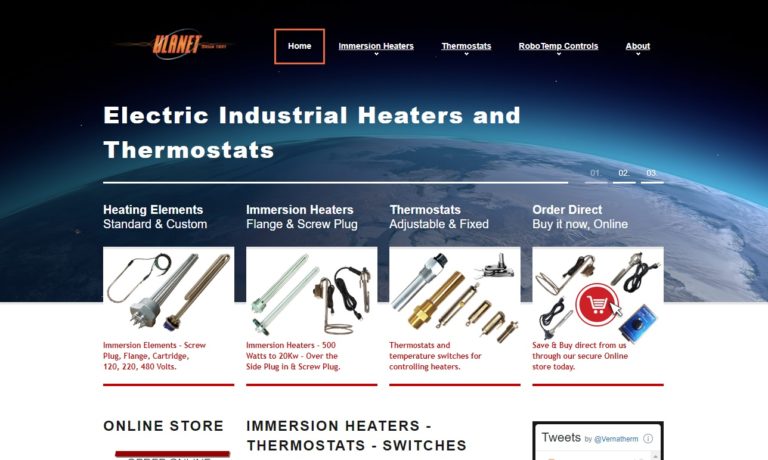

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

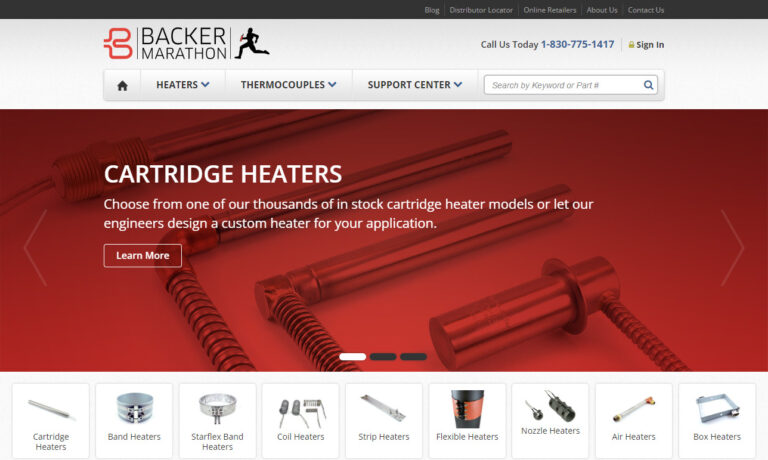

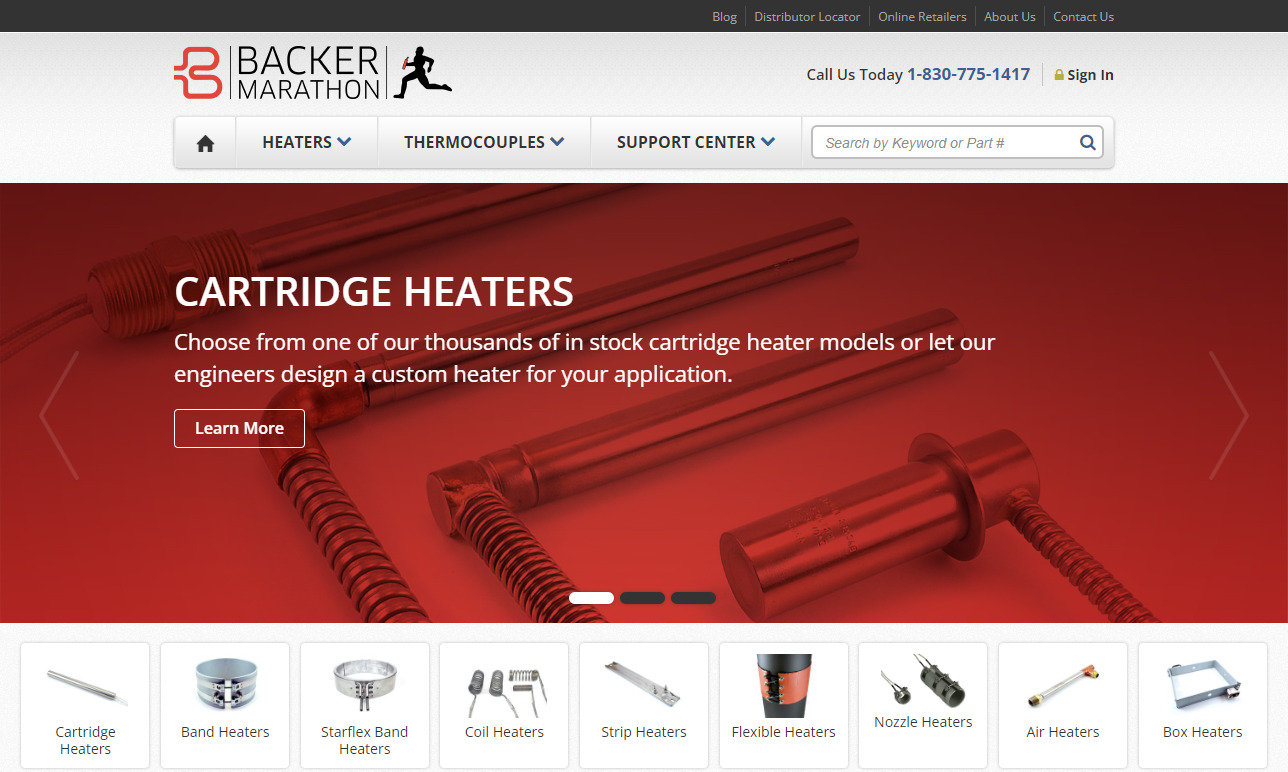

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

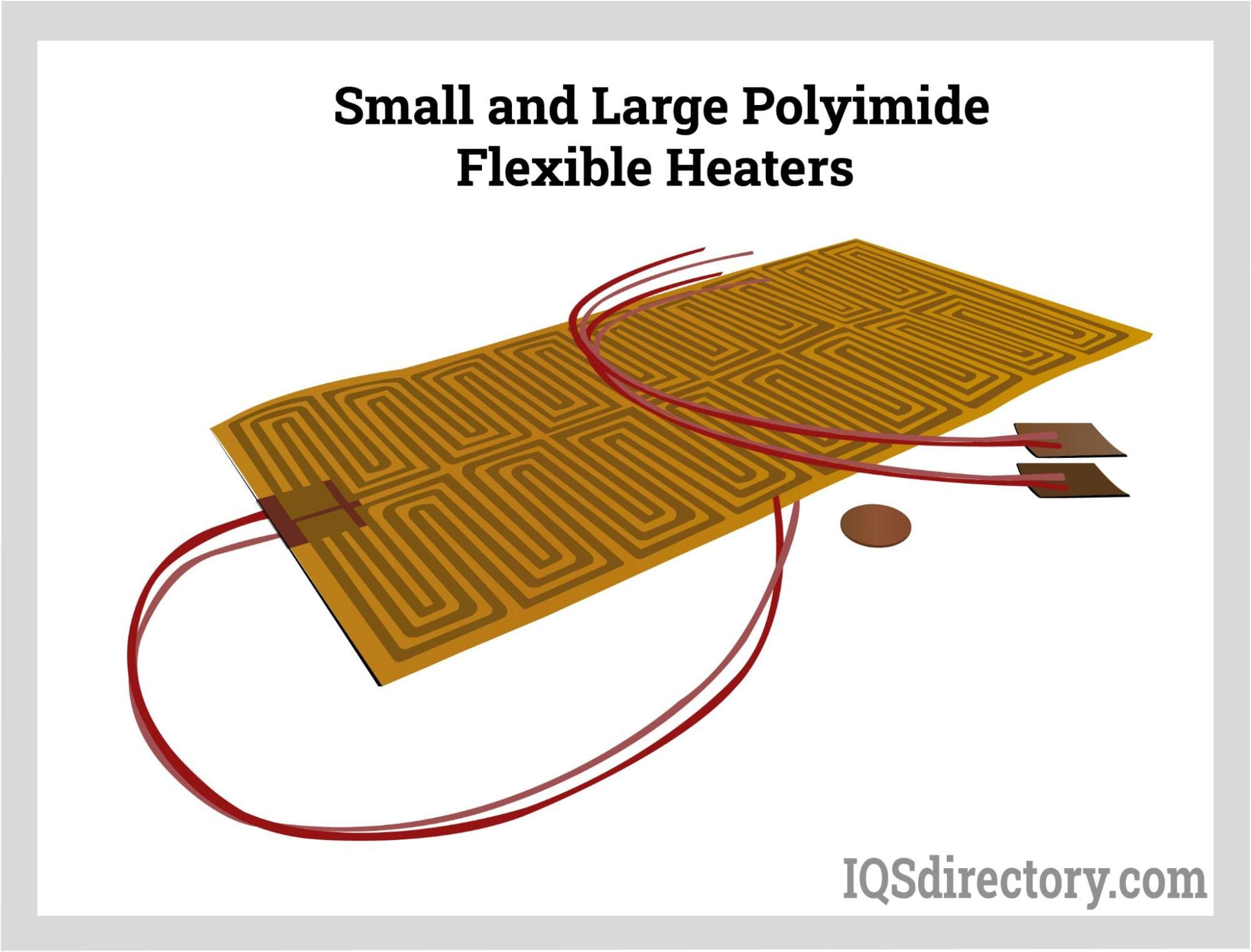

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Band Heater Manufacturers

Band heaters, as well as other small heating equipment, are required for any industrial process. They deliver direct, adequate heat in tight, irregularly shaped spaces where conventional heaters would be ineffective. Features of band heaters include cooling choices, probe holes or cuts on the band, insulated shrouds, and expanding heaters.

Materials used

Insulation materials in-band heaters are the same as those used in strip heaters.

- Resistance wire, an electric insulating substance, and a steel sheath are used to make all band heaters.

- They may be made of various materials, including minerals, mica, and ceramics.

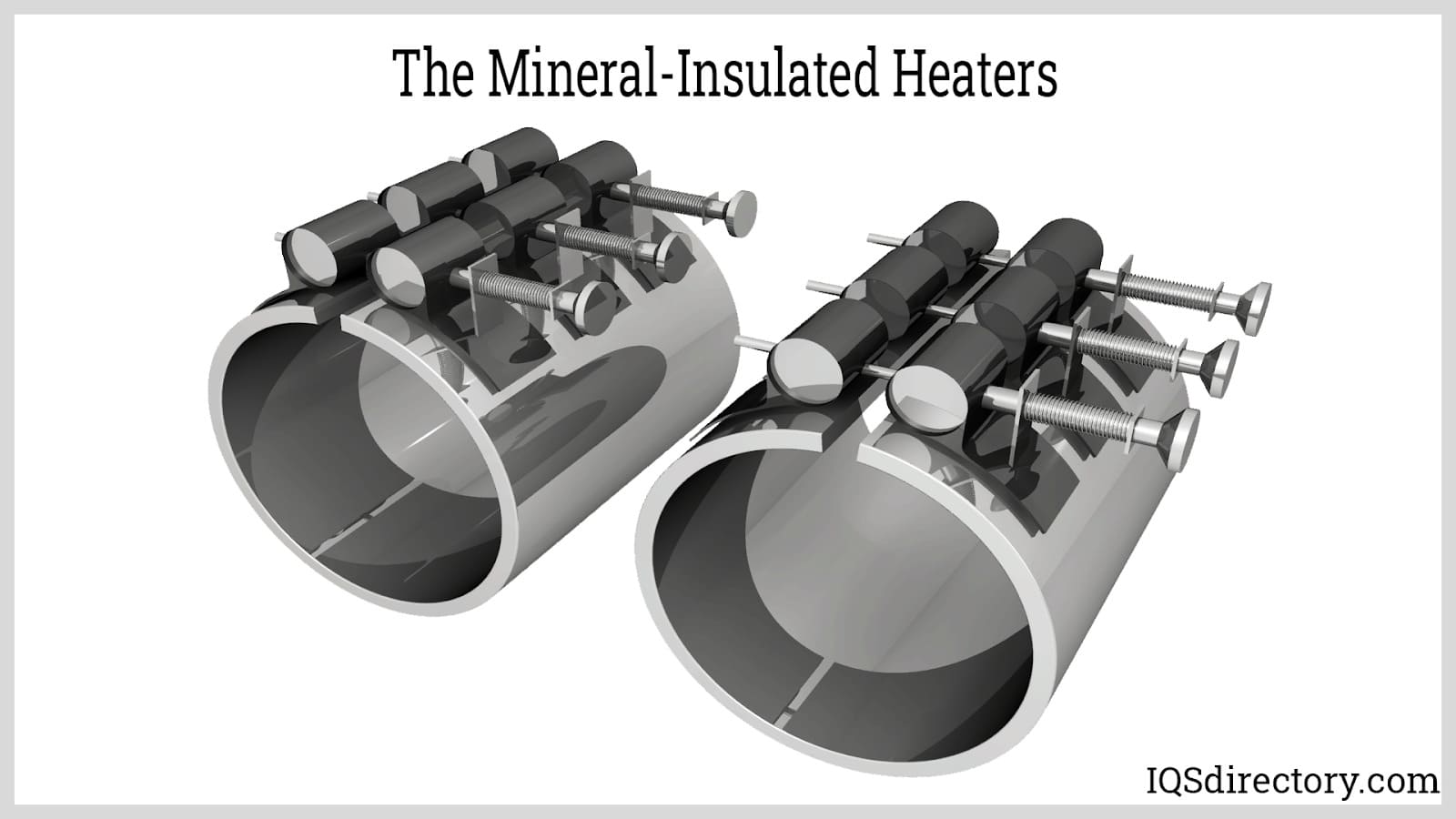

- Mineral insulated heating bands with structural stainless steel may achieve extreme temperatures; some can generate temperatures up to 1400 °F (760 °C).

Construction of Band Heaters

- The general-purpose terminal box provides good protection for exposed terminals. A standard conduit or flexible armor cable connections can be used.

- Screw terminals of stainless steel are coupled to solid nickel pins to give maximum amperage carrying capacity.

- All-ceramic bands include built-in ceramic fiber insulation, which reduces power usage by 25 to 30%. Using specially designed mounting brackets, the heating element assembly is uniformly and tightly drawn against the cylinder's width.

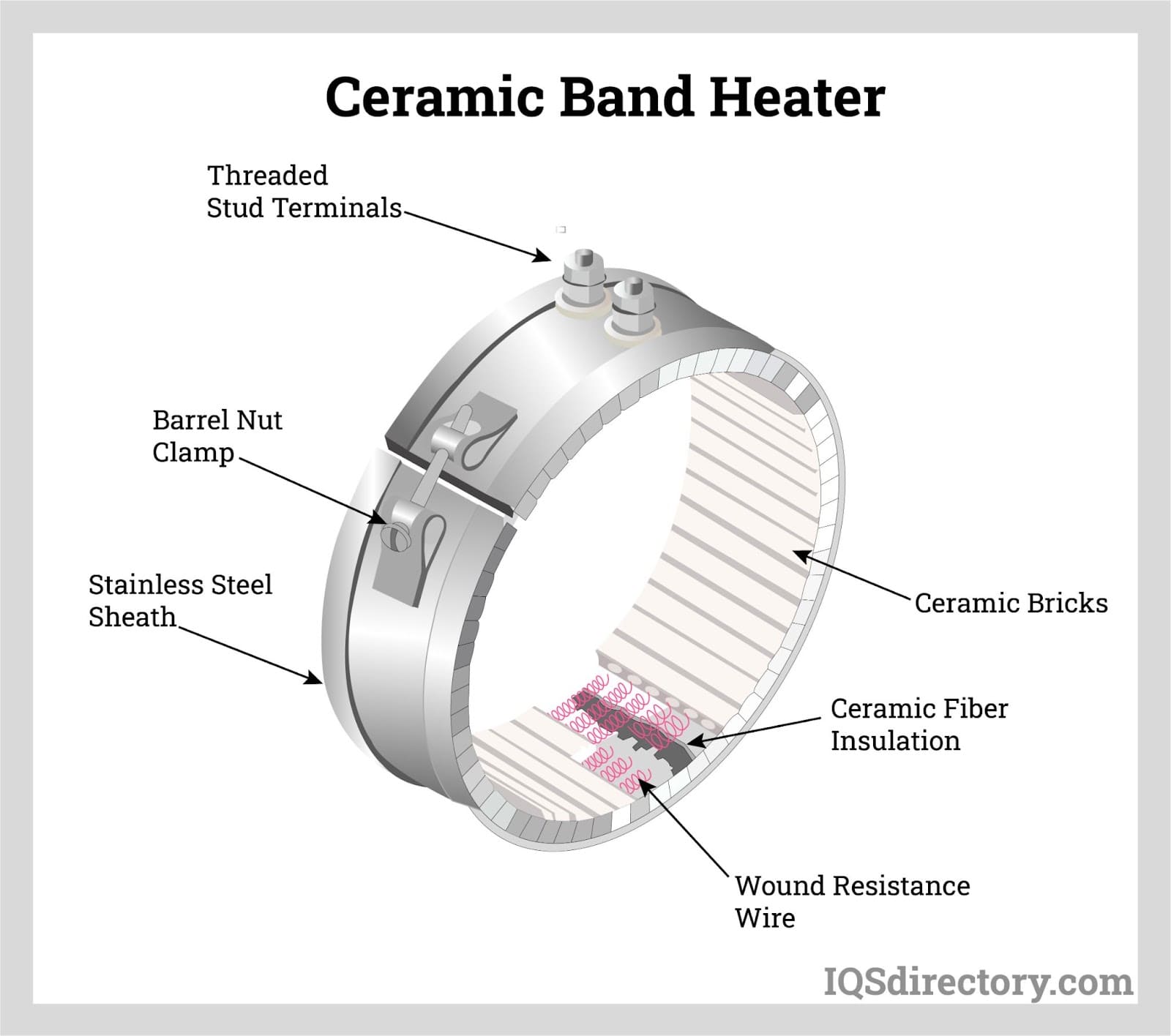

- Nickel-chrome resistance wire is helically wrapped and threaded through specially constructed ceramic insulating bricks.

- Serrated edges on the stainless-steel enclosure provide optimum installation flexibility. The method for making electrical contacts to the heater is called termination type. Armor cable leads, flexible conduit leads, braided metal leads, insulated leads, fast disconnects, and terminal boxes are all options for band heater terminals.

Working of Band Heaters

- Ceramic band heaters use infrared radiation to transport heat through the air to the object to be heated, needing no physical touch. The interior temperature of the ceramic ring is capped at roughly 1650 °F (898.9 °C).

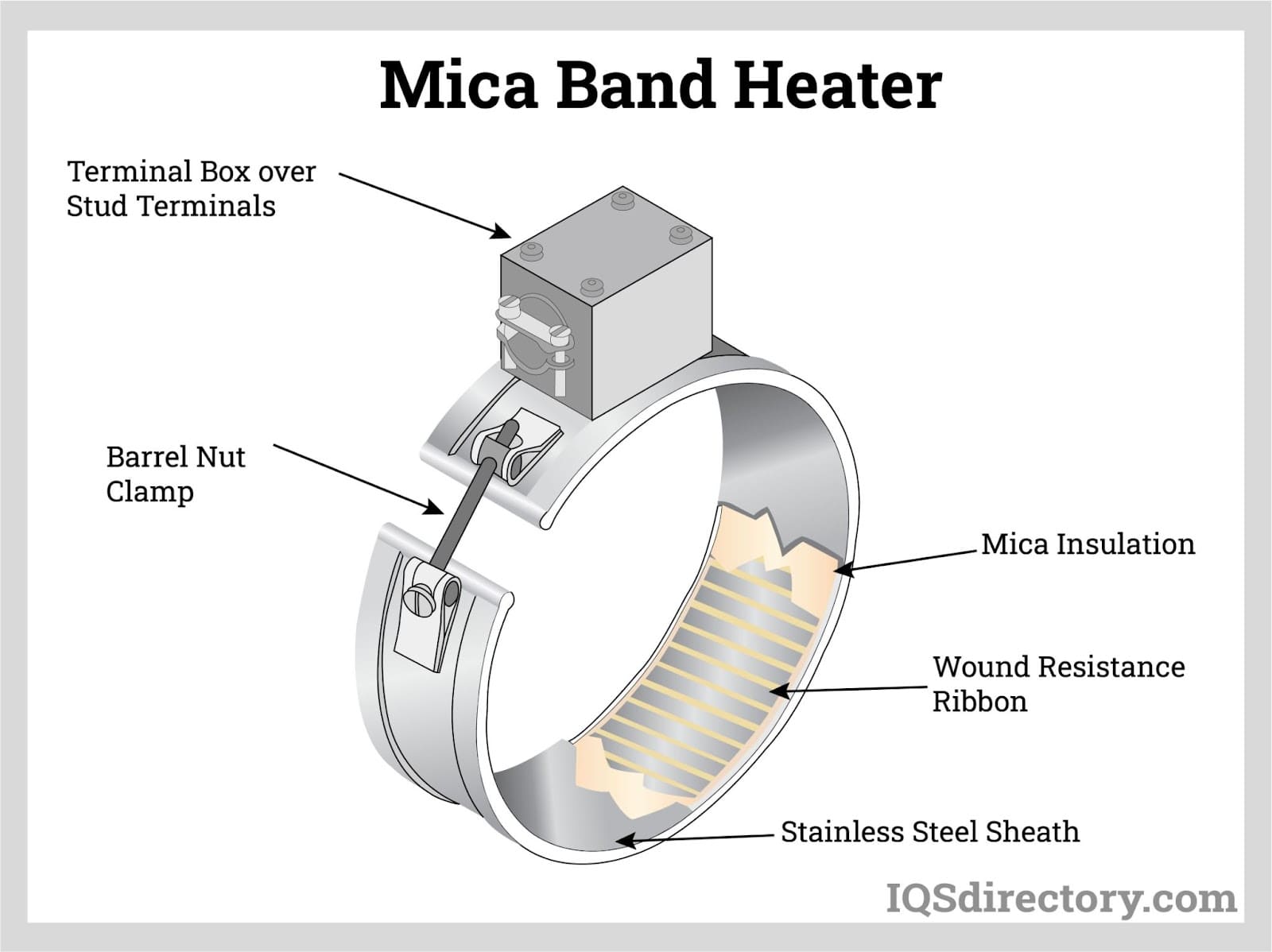

- Mica bands transmit heat from the band to the area to be heated via conduction. The interior temperature of a mica band is restricted to roughly 900 °F (482.2 °C).

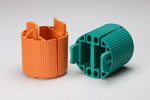

Types of Band Heaters

There are four main types of band heaters.

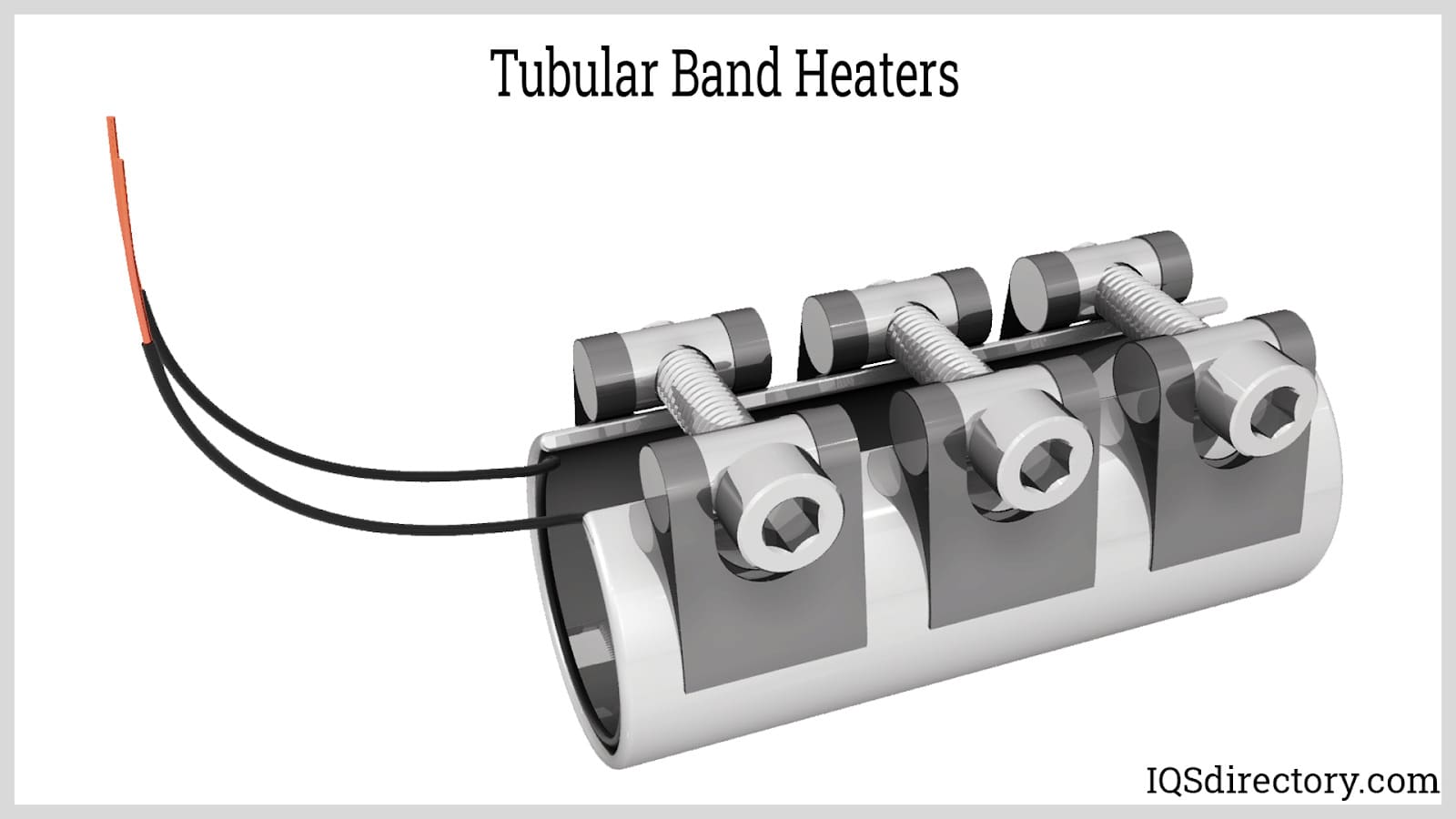

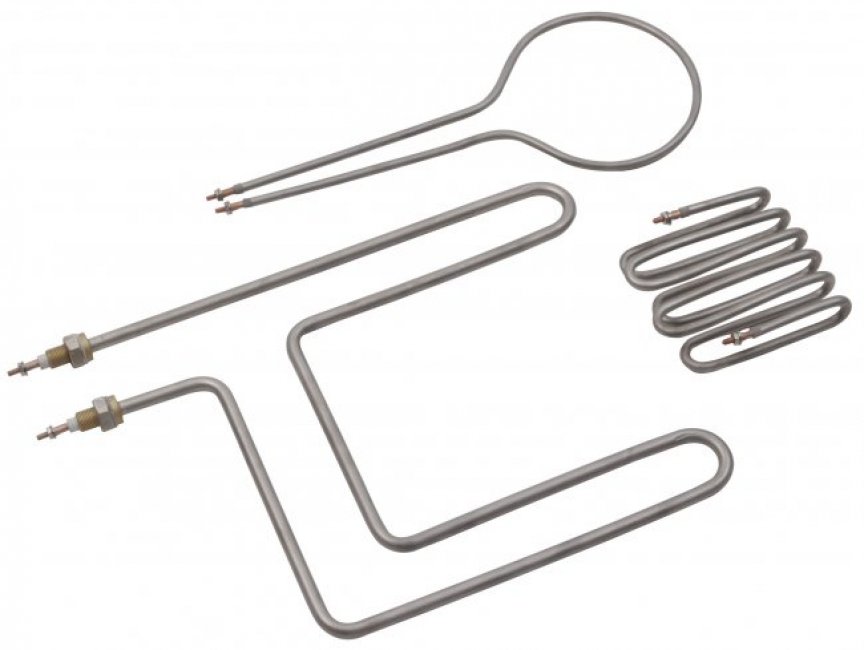

Tubular band heaters

Tubular band heaters are wide and cover a wider surface area to provide higher heat to cylinders or nozzles with smaller diameters. These heater bands are generally appreciated for their quick, easy clamp-on installation and for how quickly they produce heat.

Mica band heaters

Mica band heaters are used where a lower maximum temperature is required. It's a good insulator for heaters because it's corrosion-resistant and has good dielectric strength. It also resists chemicals and water, can be somewhat elastic, and can hold up to some bending. However, the mica band heater is less expensive.

Ceramic band heaters

Ceramic band heaters can handle high temperatures up to 1200-1400°F (648.9-760 °C). The ceramic segments used in these types of heaters make excellent insulators. In comparison, mica bands are expensive.

The mineral-insulated heaters

These are great for high-temperature applications exceeding 2000 °F (1093.3 °C). They are also considered to have very high watt densities. The typical material used is magnesium oxide, a compacted mineral that coats the band heater and provides excellent thermal conductivity.

Benefits of Band Heaters

The significant advantages of using a band heater include:

- In surface heating, heating vessels or pipes could be curved into an arc or ring-shaped cladding by winding, while large-scale steel sections can use the pavement cover. Furthermore, band heaters may be used to heat steel in a variety of geometric forms.

- They provide a high working temperature, quick warm-up, high heat efficiency, and precise heating with an autonomous control system.

- Band heaters have a long service life due to high impact toughness, strong thermal, dielectric strength, and broad surface area.

- They have low application cost due to ease of installation and maintenance, as the exterior ceramic components may be recycled even if the interior hot raw material is destroyed.

Applications of Band Heaters

- While band heaters are often used to direct conductive heating to materials such as polymer metals and plastic, they may also be used to heat conventional air.

- Convective heating transmits heat via gasses and liquids; band heaters are commonly used to heat tiny quantities of air in manufacturing and processing equipment.

- In eavestroughs and gutters, band heaters may also be employed as ice melters. They can keep drains clear of snow and ice even during harsh winters if adequately insulated and powered.

- Nearly all extrusion processes require heating; most plastic and metal extrusion procedures require the plasticization or melting of the materials to be extruded. During extrusion procedures, band heaters enhance the heat created by friction.

- Plastic extrusion, plastic injection molding, metal injection molding, front-end extrusion heating, blown film extrusion, chemical, wire processing, and food processing are some of the other band heating applications.

Choosing the Correct Band Heater Company

For the most positive outcome when purchasing band heaters from a band heater manufacturer, it is important to compare several band heater companies using our directory of band heater manufacturers. Each band heater manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each band heater business website using our patented website previewer for a better idea of what each band heater company specializes in. Then, use our simple RFQ form to contact multiple band heater businesses with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

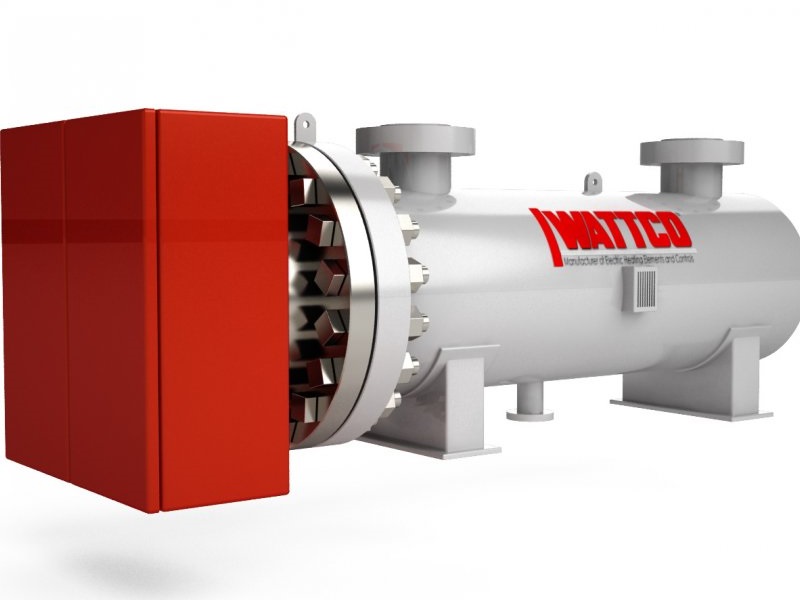

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services