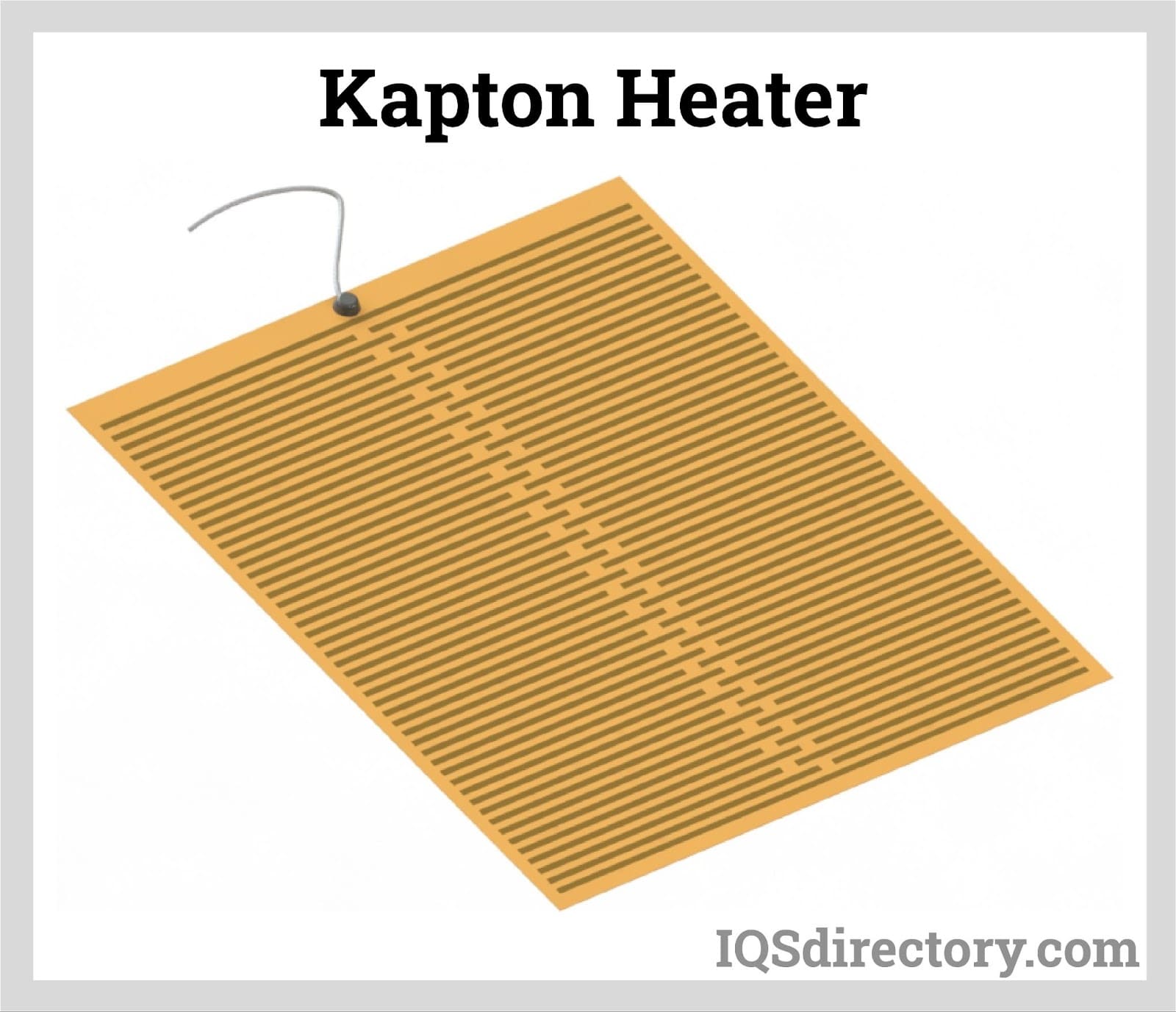

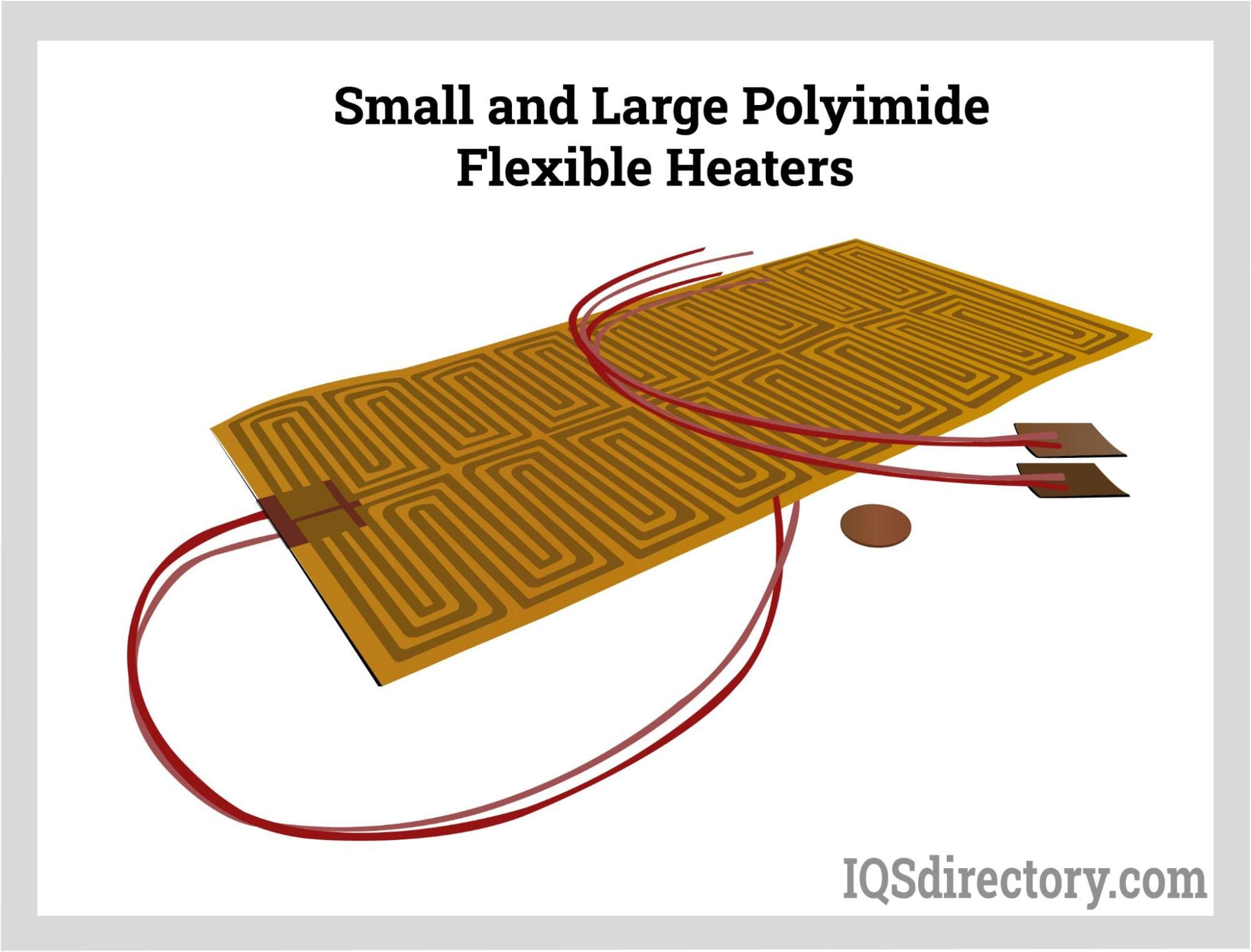

Kapton heaters, often known as Polyimide heaters, are constructed using Kapton polyimide film. Kapton heaters have the lowest profile of any flexible heater, have high tensile strength, and distribute heat evenly; they work well in hot environments and confined spaces. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

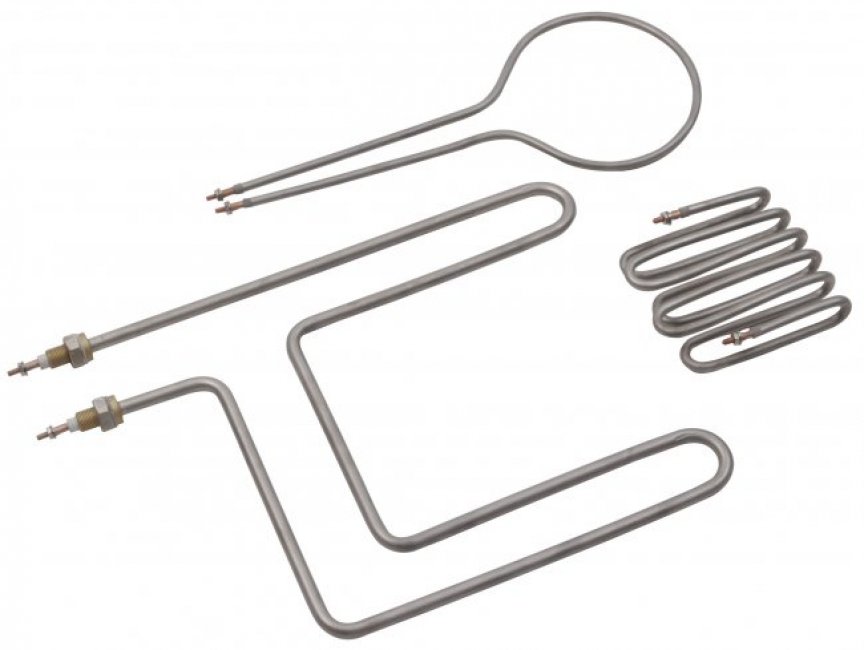

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Kapton Heater Manufacturers

During manufacturing, a pattern is cut onto the thin foil to disperse heat across a surface. Copper and constantan are some materials used to make this ultra-thin film or foil. Kapton heaters are also unusual because they can withstand radiation and resist harsh chemicals, making them ideal for industrial applications.

Polyimide film can have holes cut into it to fit around other electrical components, and specific heat sensors can be glued to the film's surface. In addition, Kapton heaters can be equipped with thermostats, thermal fuses, and specialized wire harnesses. These flexible heaters come in various forms, sizes, and wattages.

Features of a Kapton Heater

- They have outstanding physical and electrical qualities, resulting in thermal stability over a wide temperature range.

- They have outstanding physical and electrical qualities, resulting in thermal stability over a wide temperature range; various opaque variants are available.

- Kapton heaters have radiation and fungal resistance, allowing for use in various applications.

- They may be readily glued or attached to numerous surfaces or other system parts, and they are rugged, dependable, accurate, and moisture/chemical-resistant.

- They have a wattage tolerance of 10% and a maximum watt density of 50 W/in2.

- Kapton heaters have a 1000 VAC dielectric strength.

Materials Used in Kapton Heaters

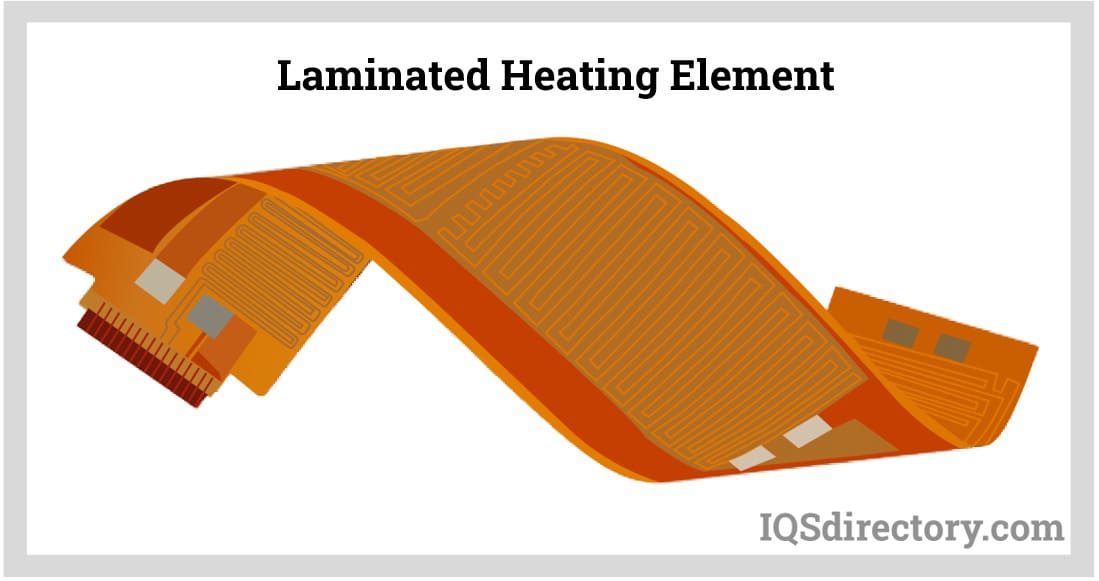

- The heating element is laminated inside a Kapton heater, and thin polyimide sheets are used as insulation.

- Its enhanced circuit imaging and printing allow designers to disperse watts and generate various heat patterns in the exact location.

- Heaters can be built for low-voltage heating or numerous heating zones when different wattages are required in other film parts.

- Adhesive tape can be used to help with the installation of other components.

- To increase heat dispersion, aluminum foil can be utilized as a backing.

- Kapton heaters can be terminated in various ways, including leads, connectors, solder terminal pads, and card-edge-ready.

Construction of Kapton Heaters

Kapton heaters may be customized to fit several industrial and commercial electrical applications.

- A typical design includes an etched foil element between two films of Kapton and FEP glue.

- The lead wires exit from the heater's breadth side's upper-right corner.

- For broad heaters only, leads exit centrally from the width side.

- The lead wires on circular heaters emerge radially.

- A pressure-sensitive adhesive option is offered. The user can also mechanically clamp the heaters or epoxy install them.

Working of Kapton Heaters

- The resistance element in Polyimide (Kapton) heaters is a thin etched metal (typically nickel-based alloy) foil.

- The etched resistance pattern is created in CAD and then transferred to foil, acid sprayed to generate the appropriate resistance pattern.

- Its slim and light profile and high watt density allow for precision heat distribution at a cheap cost of operation.

Benefits of Kapton Heaters

- A Kapton heater can direct heat where it's required, including heat profiles that can be regulated.

- Kapton heaters' thin structure allows them swift thermal transfers, resulting in faster heat.

- Kapton heaters can withstand extreme temperatures from -328 °F to 329 °F (-200 °C to 165 °C) due to the Kapton film's thin profile and versatile capabilities.

- Kapton heaters use polyimide films, which are thin and lightweight, solvent resistant, dimensionally stable, and have excellent tensile strength and tear resistance. They also offer a high level of vibration resistance in industrial applications.

- Kapton heater heating components are polyimide, which has minimal outgassing qualities.

- Kapton Heaters are suited for situations requiring a lightweight solution or quick heat-up time.

Applications of Kapton Heaters

- This cutting-edge technology has analytical test equipment, LCD screens, and military equipment applications.

- Even crucial aircraft electronics are safeguarded by these specific heaters, ensuring that the aircraft's electrical systems are not harmed during a power outage.

- Electronics that may need to operate in cold temperatures, such as ATMs or laptops, nearly usually include an incorporated Kapton heater to maintain all of the other parts at a functioning temperature.

- Kapton heaters are used in medical diagnostic tools such as heat sample trays, reagent bottles, and CPAP ventilator humidifiers, among other things.

- Optoelectronic components are stabilized using Kapton heaters.

Choosing the Correct Kapton® Heater Company

For the most productive outcome when purchasing a Kapton® heater from a Kapton® heater supplier, it is important to compare several suppliers using our directory of Kapton® heater businesses. Each Kapton® heater company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each Kapton® heater company website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple Kapton® heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services