Most clamp-on installations and convection-style air heating involve the use of strip heaters. There are two key elements to consider while choosing strip heaters: the appropriate sheath material to withstand the required sheath temperature and any inherent corrosion and oxidizing in the process or environment. Typical sheath materials include Incoloy, chromium steel, and rust-resistant iron (NS series only). Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

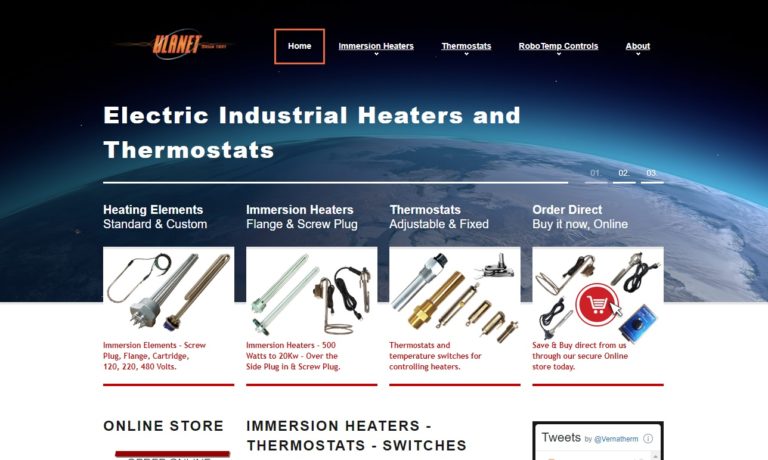

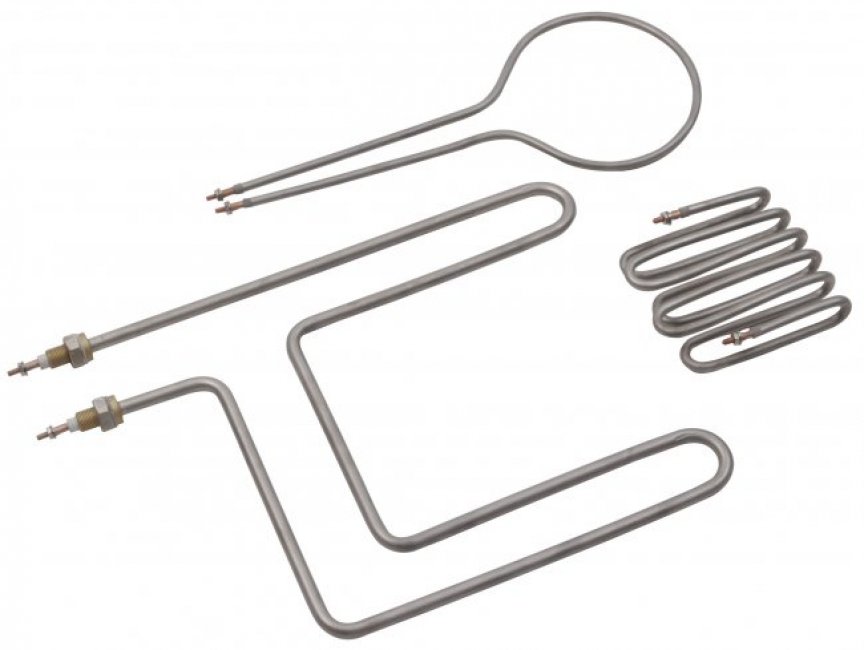

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

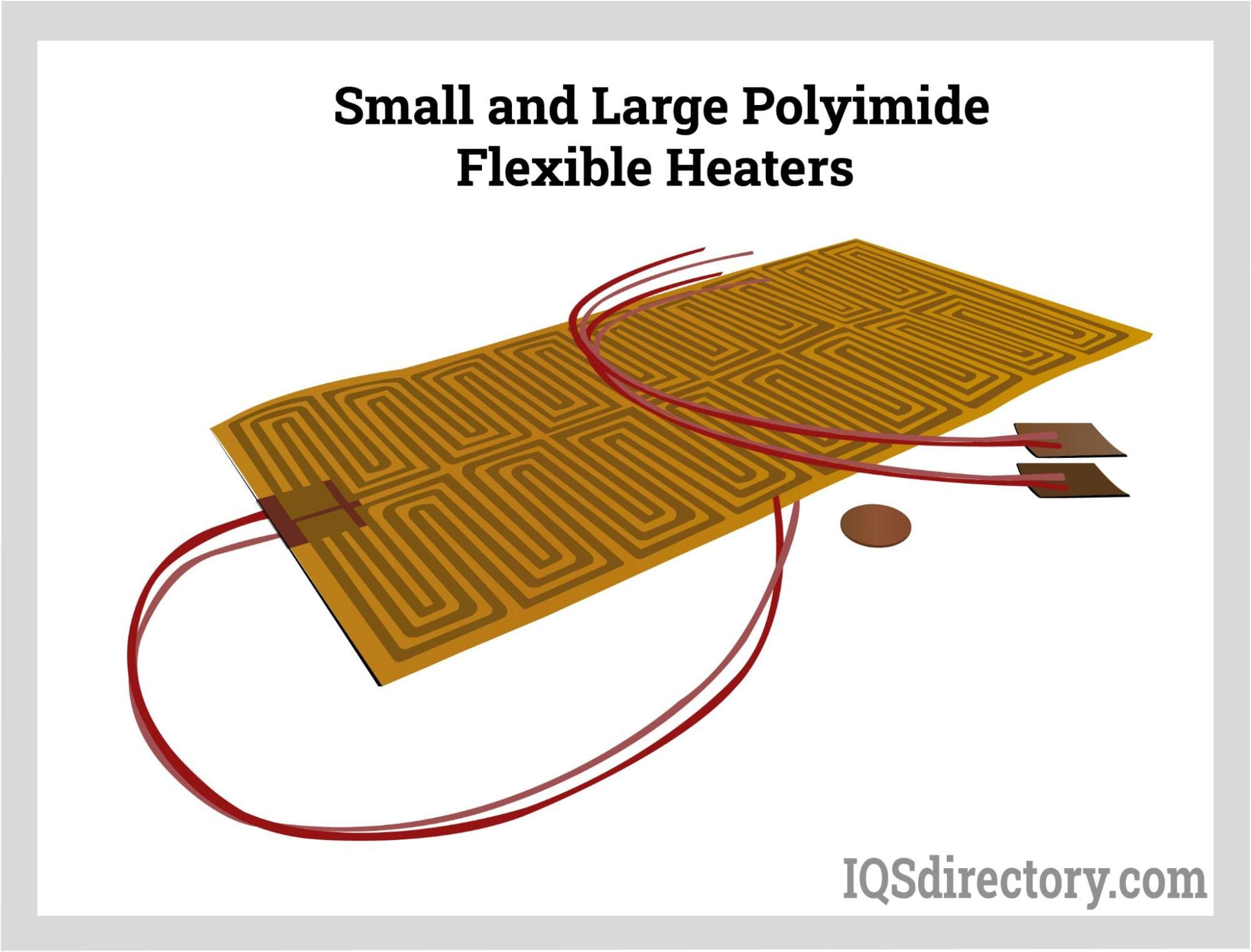

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

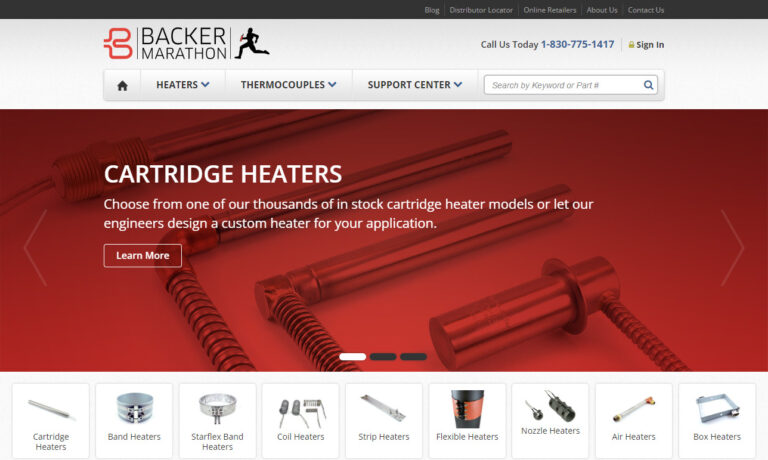

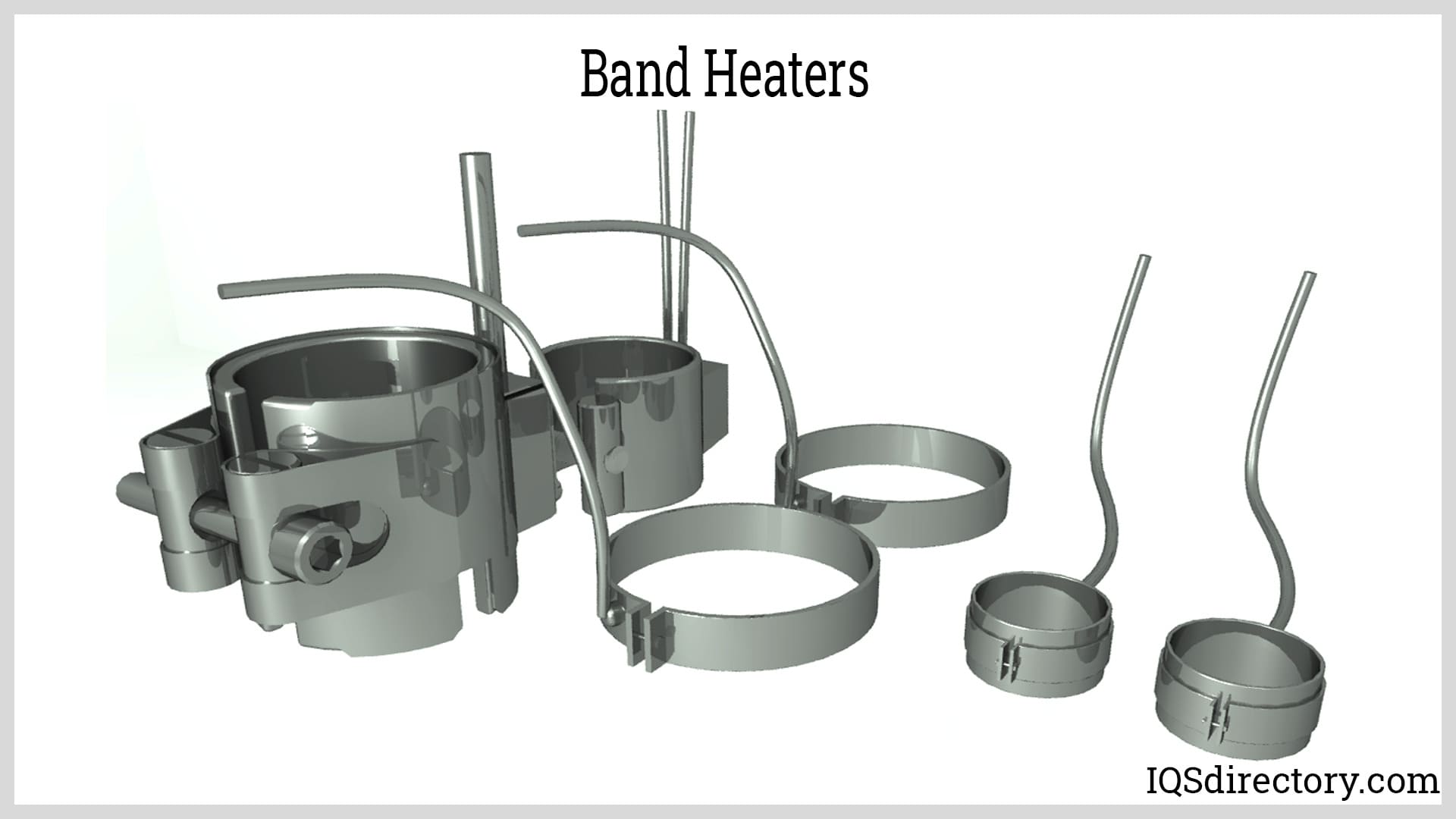

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Strip Heater Manufacturers

For heating asphalt, molasses, and other dense materials with low heat transferability, the heating element's watt density should be low; heating air, metals, and other heat-conducting materials can be higher.

Types of Strip Heaters

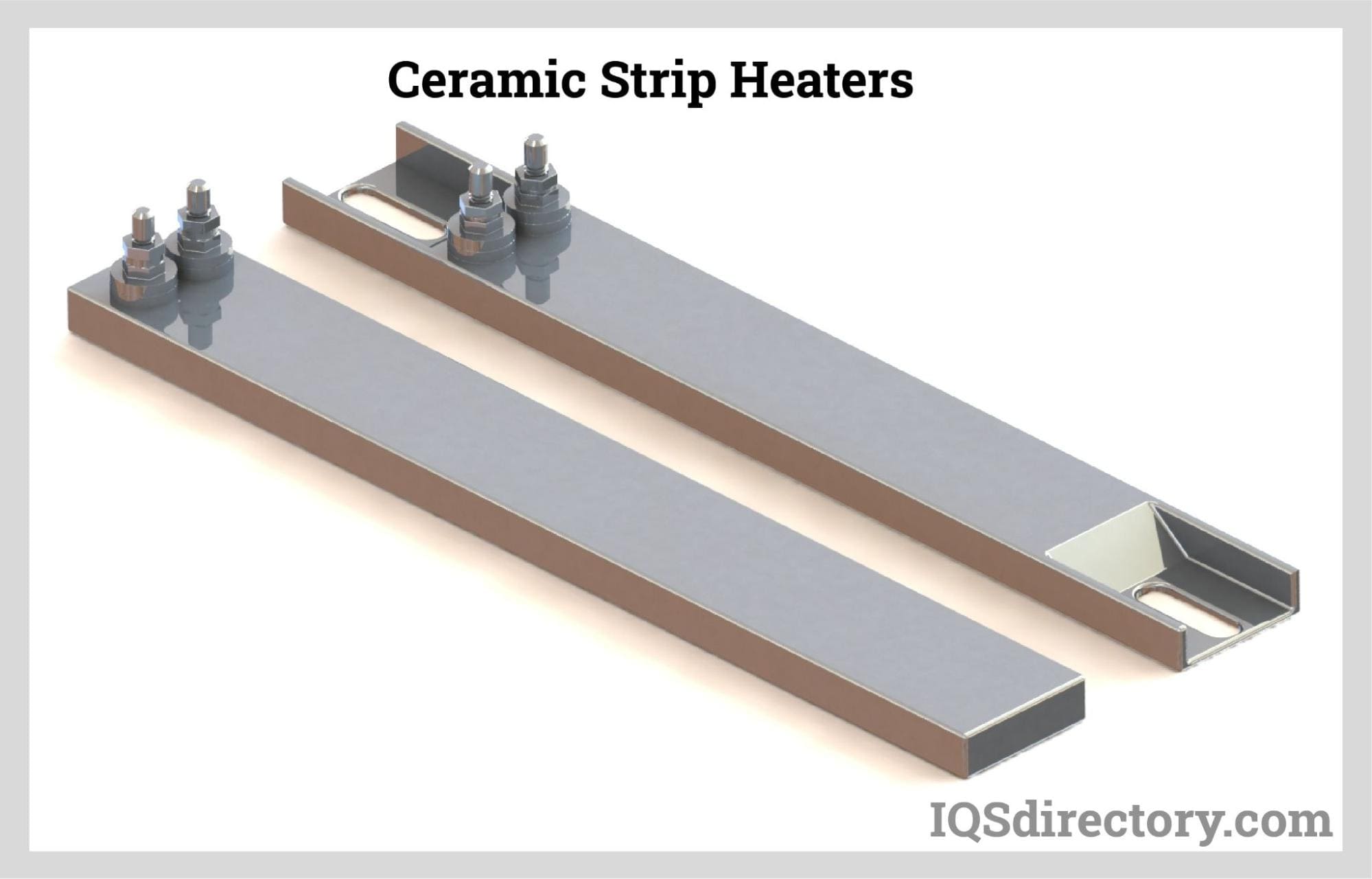

Ceramic Strip Heaters

A chromium resistance wire coil inside a ceramic core, inserted in a metal sheath and loaded with magnesium oxide for optimal heat transfer, makes up ceramic strip heaters. This structure provides the long life required for demanding applications.

Strip heaters are a piece of superb industrial heating equipment that works wonders for surface heating applications. To provide equal heating, they are made of resistance wire that has been uniformly coiled and stretched inside a ceramic insulator along the heater's length and width. It is encased in a stainless-steel sheath to provide the assembly with great mechanical strength and corrosion resistance. It also has high-purity magnesium oxide inside it to remove any air pockets, resulting in outstanding thermal conductivity and dielectric strength.

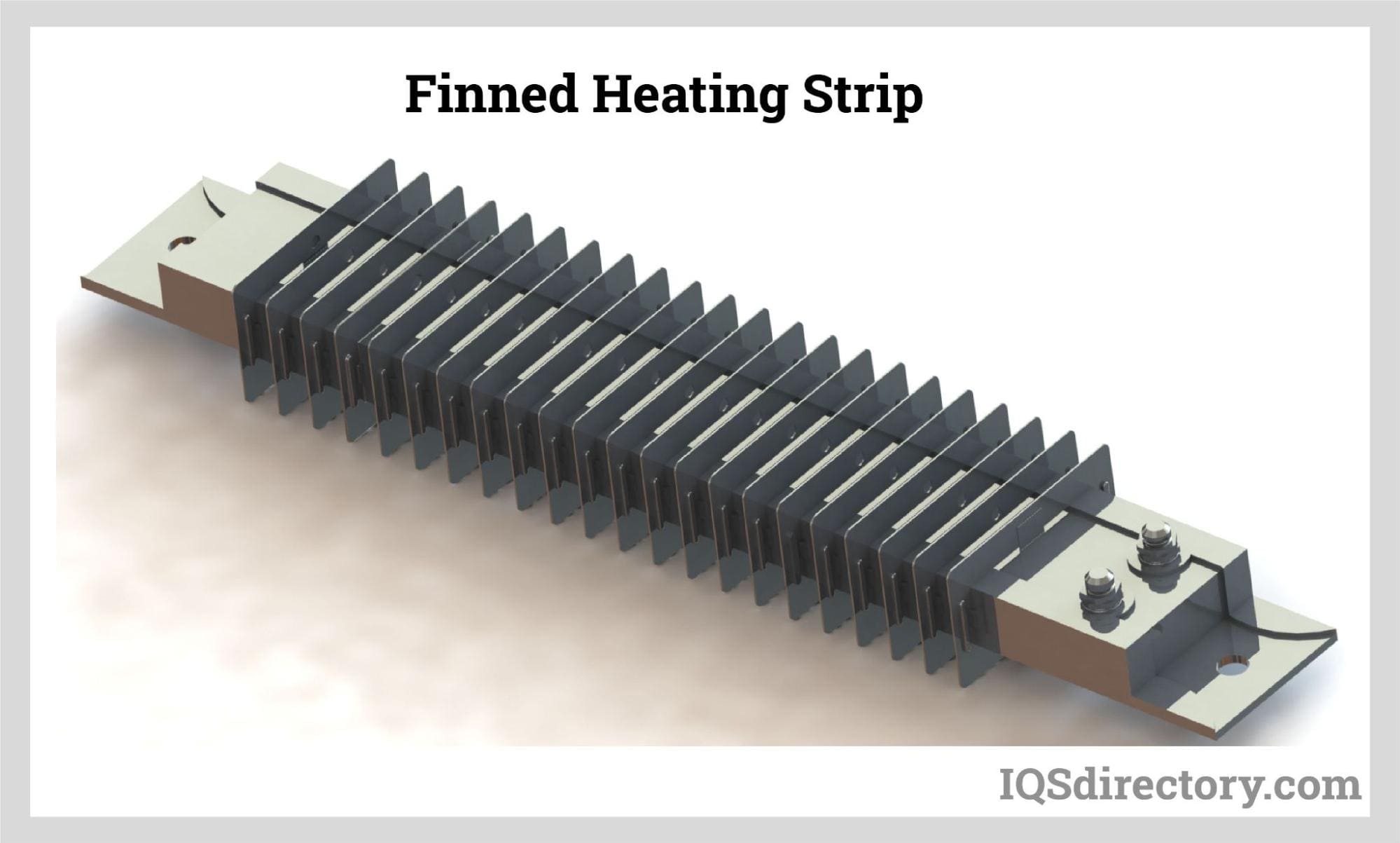

Finned Heating Strips

The finned band element has a high-quality nickel-chromium tubular resistance wire uniformly distributed over its width and length. The wire is then immersed in a high-quality refractory substance, which insulates it and has a rapid heat-transfer rate. Heat conduction from the coil to the sheath is enhanced by compacting the refractory with maximum density under high hydraulic pressures. Next, they are baked at high temperatures to semi-vitrify the components and prepare the refractory.

The sheath is made of either chromed steel or corrosion-resistant iron. Fins made of aluminum-coated steel are offered to improve this transfer to air. Finned strip heaters are used for forced and natural convective air heating and each of its parts. Permanent furnace brazing secures continuous spiral fins to the sheath. This finned structure maximizes element life, lower sheath temperature, and improves heat transmission in forced or free air heating applications.

Ring Heating Tapes

Installation of ring heating tapes is simple. They are perfect for heating tank bottoms, lead melting points, dies, trays, hotplates, incubators, and many more applications because of their flat circular design. Additionally, heat tape protects while wave soldering delicately-printed circuit board (PCB) components like gold fingers. Because of this, heat-resistant tape is widely used in the electronic sector as heat tape for transformers, motors, coils, capacitors, and frequency conversion power supplies.

Factors Considered When Selection a Strip Heater

The best kind of strip heater for a given application can depend on various criteria. The factors below should be considered when selecting a strip heater:

- Physical dimensions – width, strip length, or thickness

- Power requirements and electrical power outputs –maximum operating temperature, AC voltage, and watt density

- Features – enclosed sides, coil patterns, open elements corrosion resistance, instrumentation cutouts

- Termination types:

- There is a post at each end of the heater's opposite end posts.

- Insulated leads

- Along the heater's length, tandem posts are spaced one after the other.

- Metal braided leads

- The width of the heater is lined up with parallel ports.

- Flexible conduit leads

- One end of a three-post terminal has a single end post, and the other has two.

- The heater has horizontal leads positioned throughout its length.

- There is an enclosure for the terminal box connections on the heater's surface.

Applications of Strip Heaters

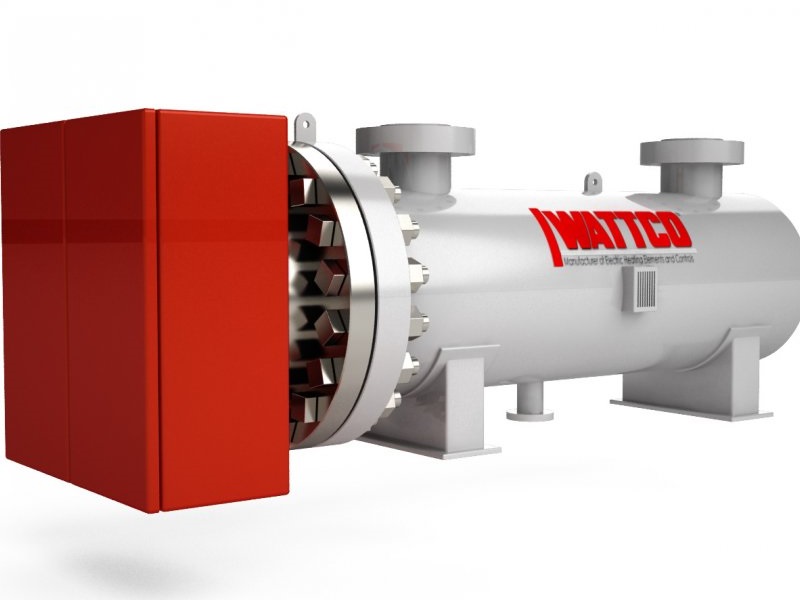

Strip heaters, often called component heaters, can be fastened with bolts or clamps to solid surfaces to distribute heat across a wide area. Additionally, they include fins that enable them to promote heat transfer and maximize the heated surface area. They work well for most surface heating and process air heating applications due to their distinctive and adaptable design.

Strip heaters are used in the following ways:

- Hoppers

- Molds

- Pipes

- Extruder barrels

- Ovens

- Conveyors

- Dies/tooling

Benefits of Strip Heaters

Some of the benefits of strip heaters include the following:

- High Operating Temperatures: Mica, channel, and mineral-insulated heaters have high operating temperatures even though the resistance varies by design.

- Versatility: Strip heaters' highly adjustable designs make them ideal for various applications.

- Easy Installation: Strip heaters are simple to mount to the equipment and alter.

- Fully Customizable: Strip length, width, thickness, termination types, and power and electrical output needs can be customized according to the application.

Drawbacks of Strip Heaters

- The heating strip can react chemically with the sample.

- It is difficult to measure the sample temperature accurately.

- The power requirement is high.

Choosing the Right Strip Heater Company

To ensure you have the most productive outcome when purchasing a strip heater from a strip heater supplier, it is important to compare several strip heater companies using our directory of strip heater suppliers. Each strip heater supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each strip heater business website using our proprietary website previewer for an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple strip heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services