In a specialized system, process stream, or closed settings, industrial heaters convert the energy of a fuel or another energy source into thermal energy. Heat transfer is the process through which thermal energy is transferred from an energy source to a system. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

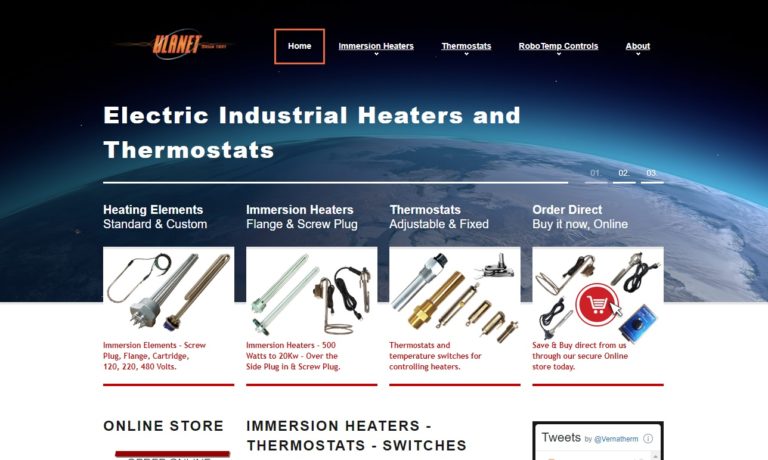

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

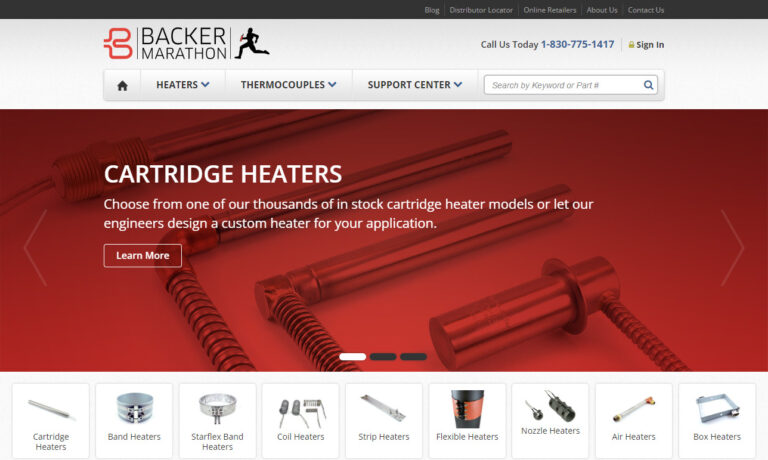

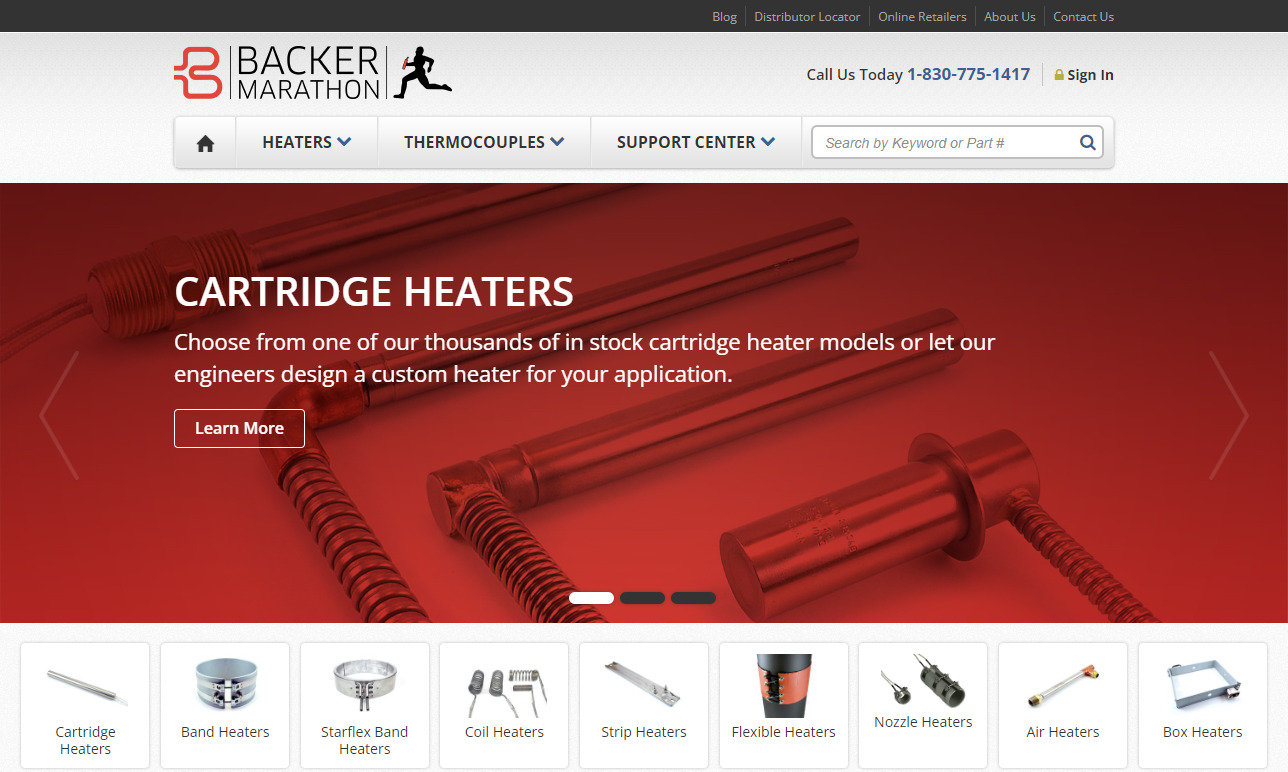

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Industrial Heaters Manufacturers

Industrial heaters use one of three transmission methods: connective, conductive, or radiant. Heat transfer happens in a convective manner when heat is transmitted owing to the motion of a fluid. In the conductive approach, heat transfer is the most prevalent way of heat transmission through solids. In the radiant technique, heat transfer is heat transmission via electromagnetic waves.

Materials Used

They constantly require an energy source, and if you pick the incorrect type, they may be relatively energy-intensive to run.

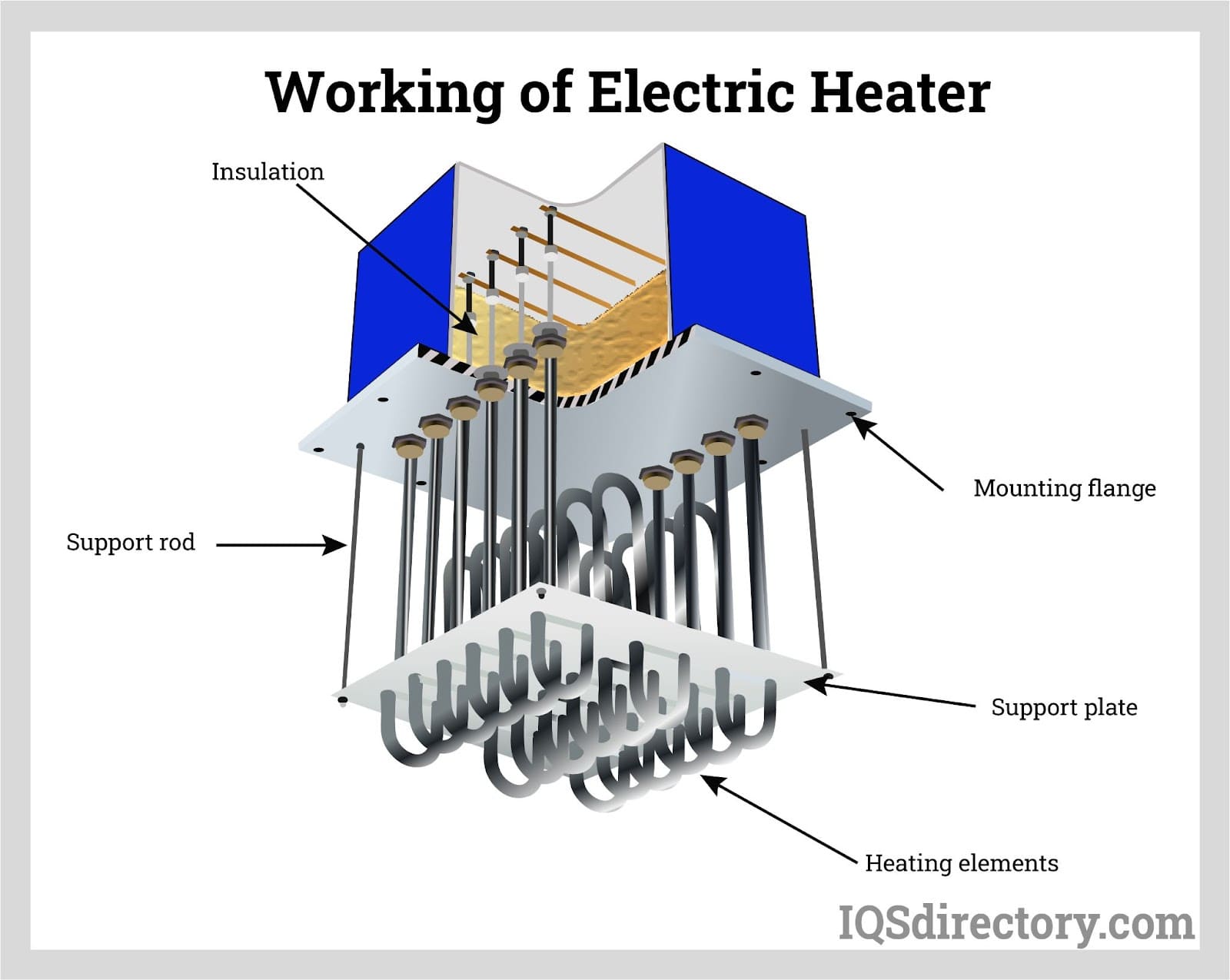

Sheath or Sleeve Material is required for industrial heaters. Brass, aluminum, iron-nickel alloy, steel, rubber, and stainless steel are all options for sleeve materials.

Modern resistors employ an electric resistance heating wire.

Industrial heaters must have a termination foundation, which necessitates the use of a terminal.

Coil heaters contain a multilayer heating element primarily insulated with nickel nickel-chromium, which has strong resistive qualities and can create heat.

Ceramics, mica, magnesium oxide, fluoropolymer, and fiberglass are insulating materials.

Construction of Industrial Heaters

Distinct industrial heaters have different building procedures; however, an electric industrial heater's construction process is detailed here:

Using your wire cutters, cut two sections of electrical wire.

Connect the opposing end of the dry cell battery to one end of one exposed wire. To hold the wire in place, use electrical tape.

Connect the positive end of the dry cell to one end of the second piece of wire. To hold the wire in place, use electrical tape.

On the table, place the ceramic plate. Toss a handful of steel wool onto the ceramic plate. Make sure the steel wool isn't too tightly packed so that heat may freely pass through it.

Insert the negative and positive wires' remaining exposed ends into the steel wool. From the cell, the thread will begin to create heat.

Types of Industrial Heaters

Strip Electric Heater

A strip electric heater is a flat device put on a surface that heats the character or the air around it. Fins on finned strip heaters improve heat transmission.

Ring Heater

A ring heater is a device that heats the inside of a ring. Ring heaters are unique strip heaters that heat circular things like the bottom of a tank, dies, or molds.

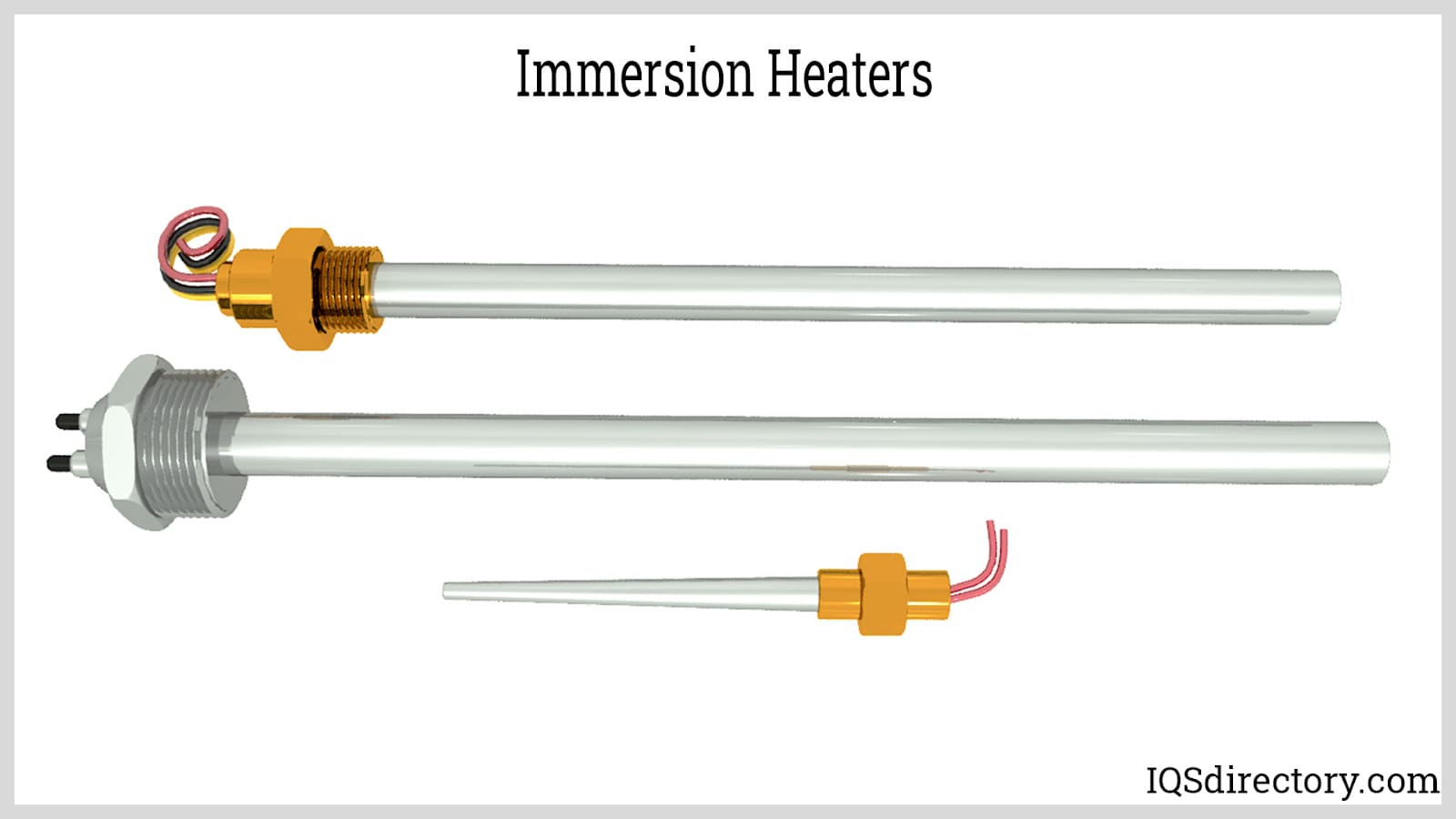

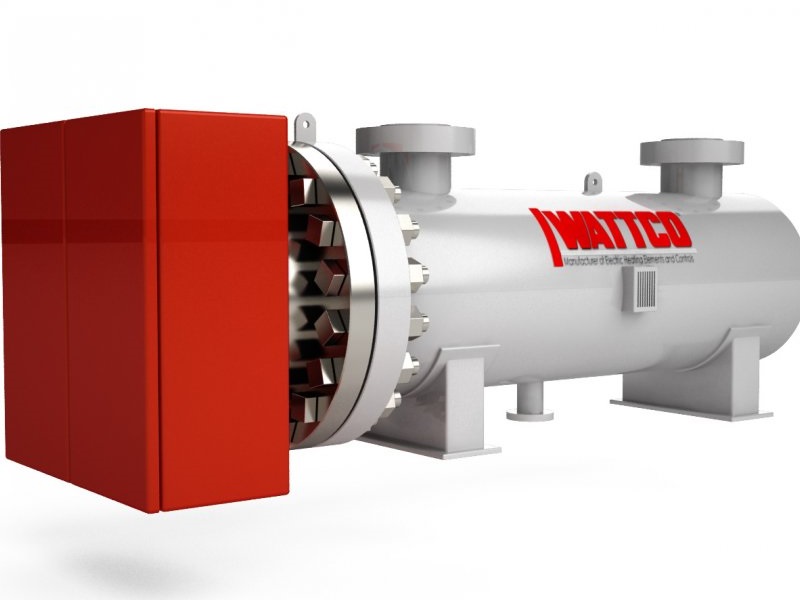

Immersion Heaters

An immersion heater is a type of heater that is used to heat liquids, oils, and other viscous fluids directly. Immersion heaters are placed in a liquid-holding tank. They are an effective way of heating liquids since the heater is in direct contact with the fluid.

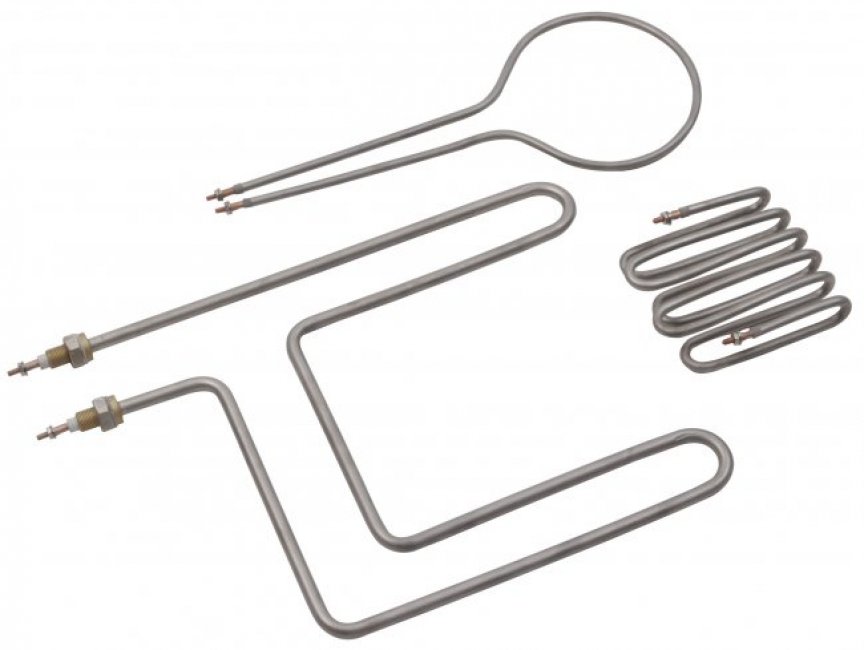

Tubular Heaters

A tubular heater is a type of heater that uses conduction, convection, or radiant heat to heat air, gasses, or liquids. Tubular heaters have the benefit of being able to be constructed with a range of cross-sections and route shapes to maximize heating for a particular application.

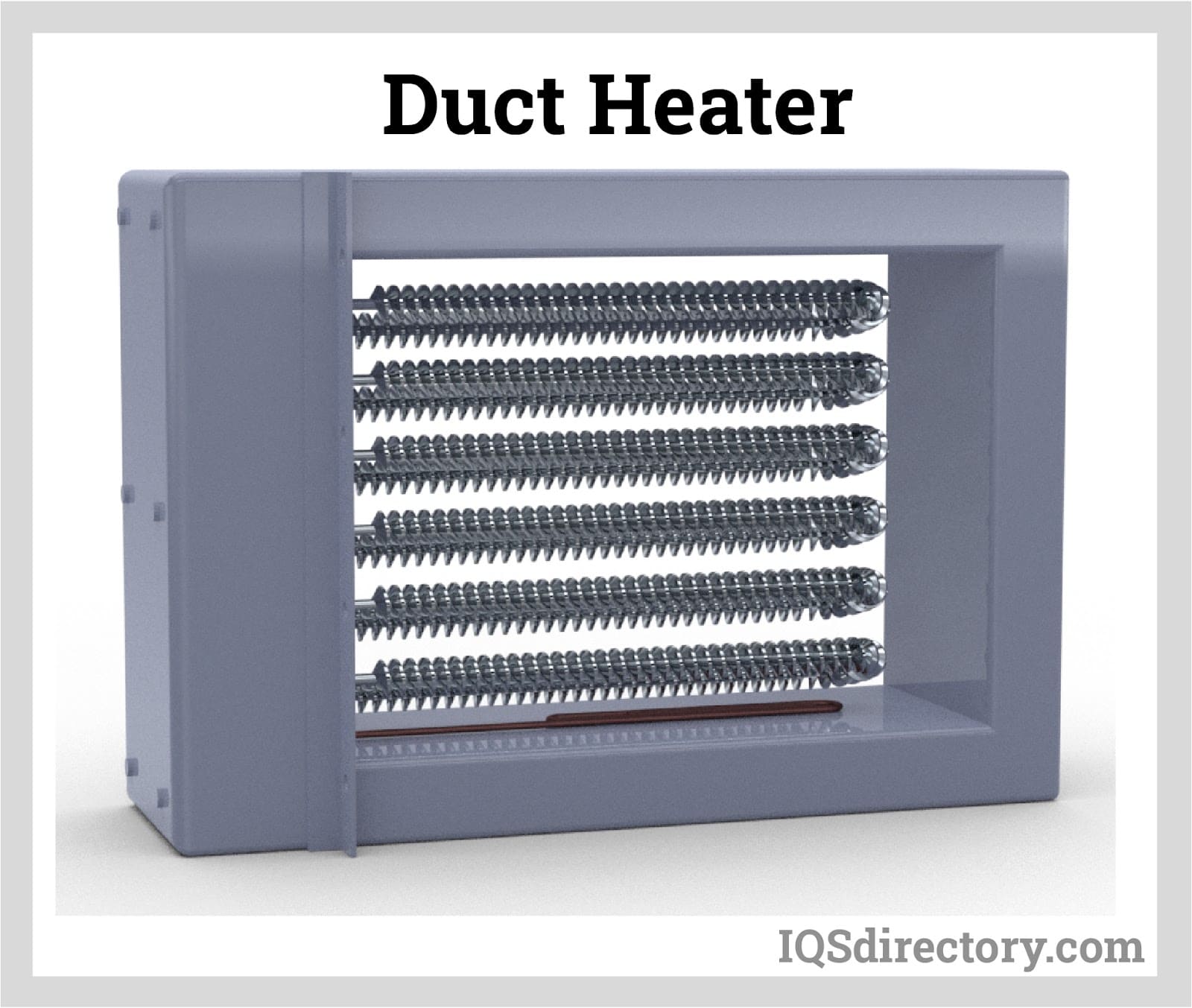

Duct Heaters

An electric duct heater heats the air as it passes through ducts. Square, spiral, round, and other duct heaters can easily fit into various HVAC and industrial ducts.

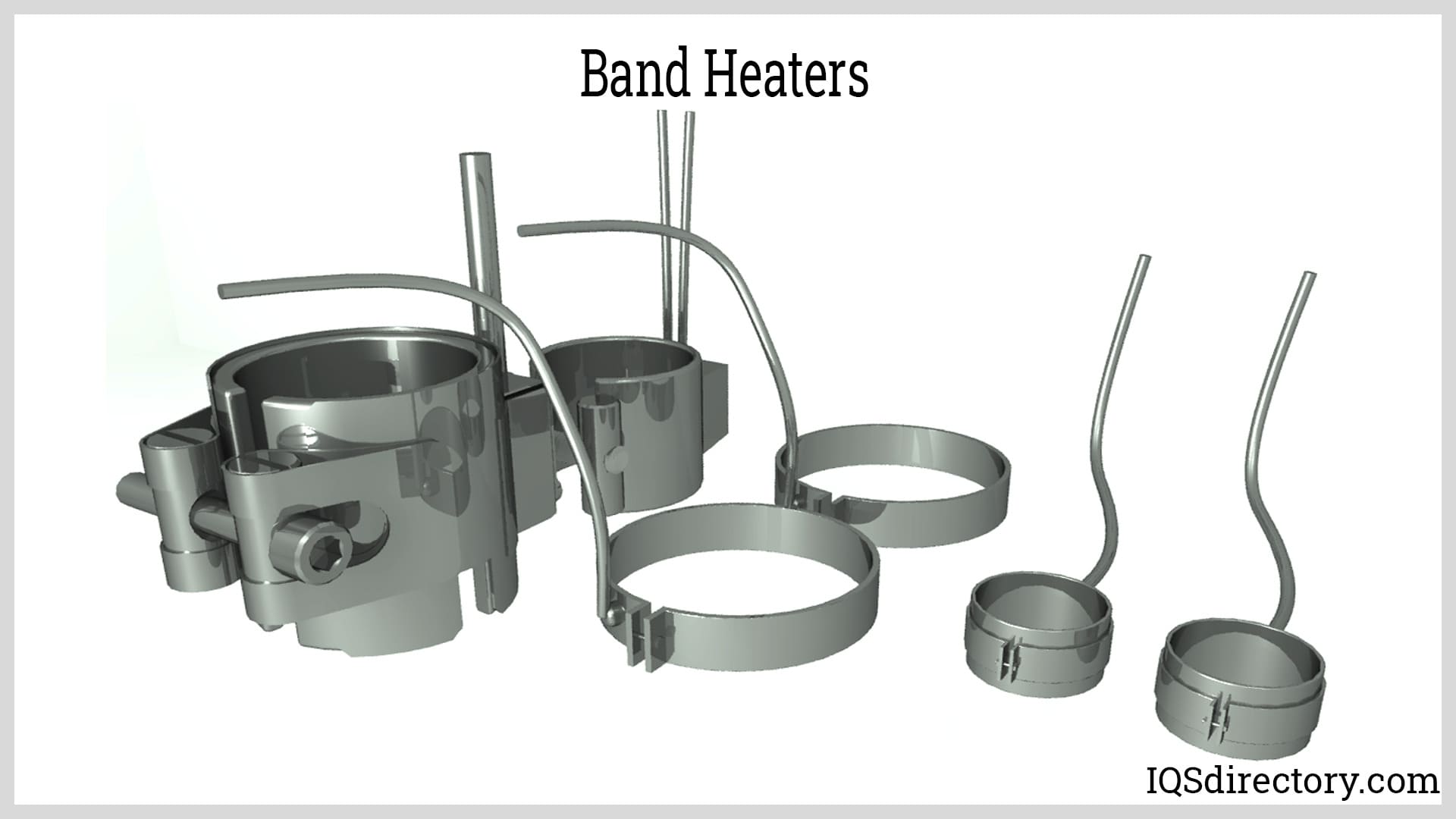

Rope and Band Industrial Electric Heaters

These are flexible heaters wrapped around pipes, beakers, and other circular surfaces.

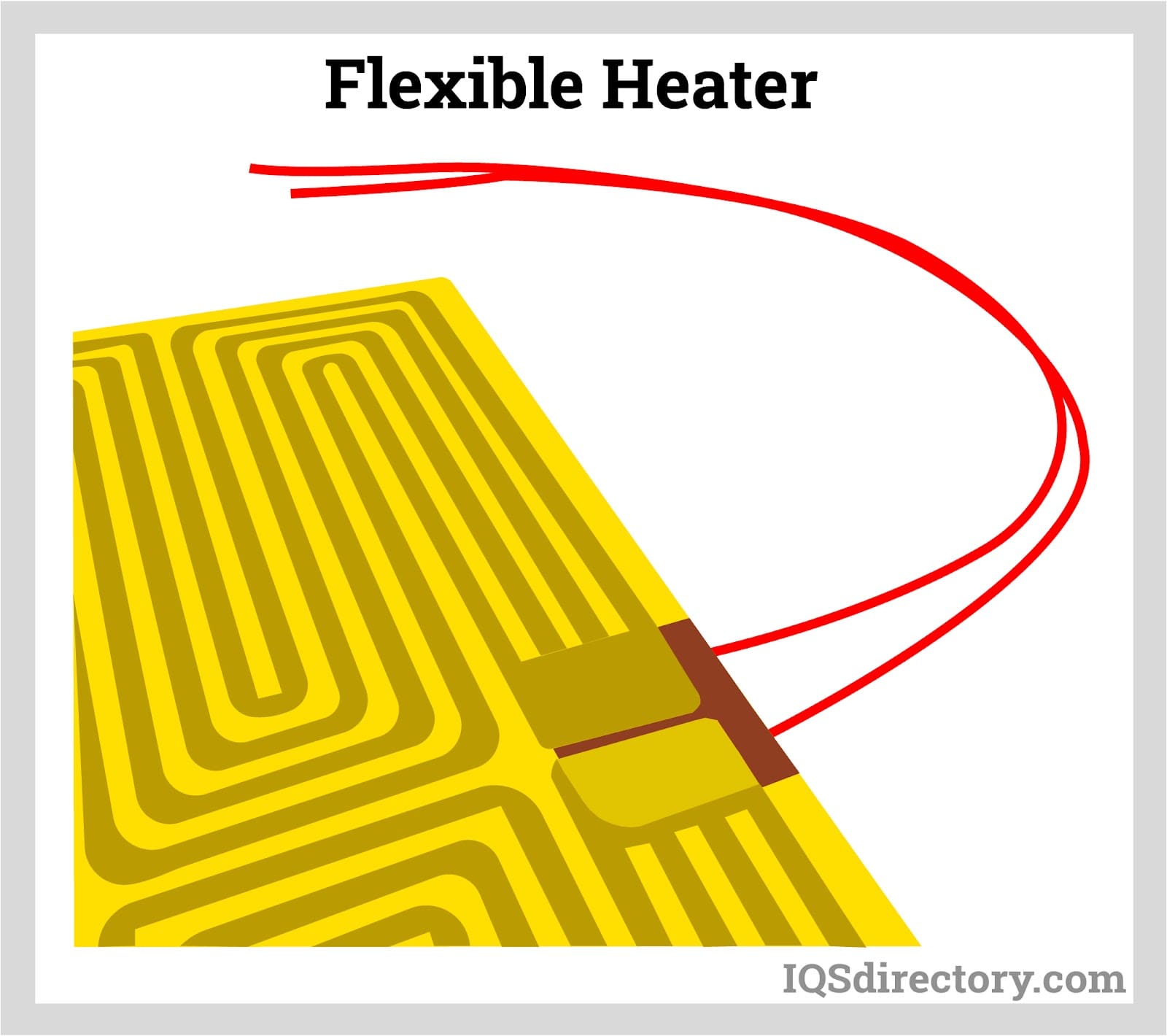

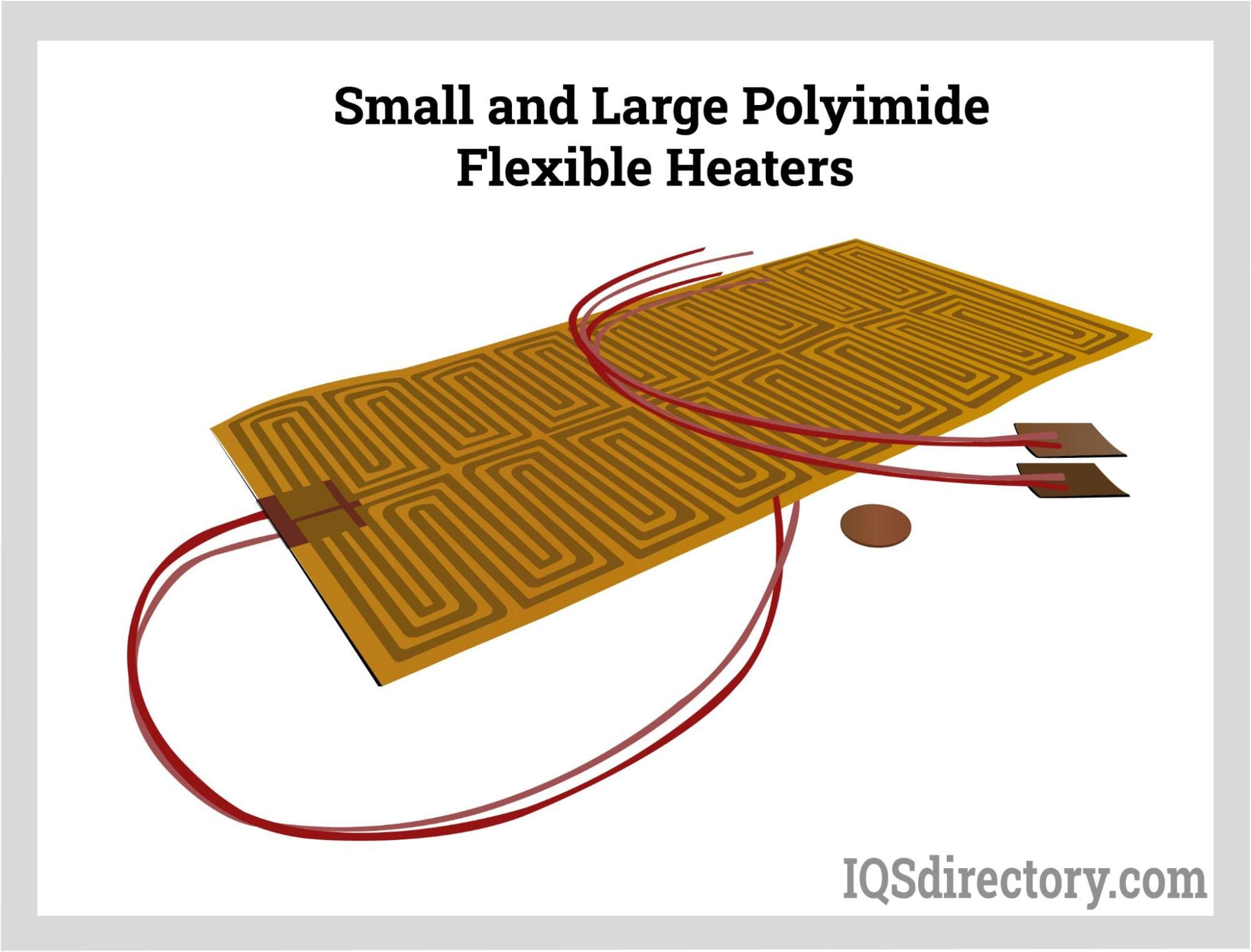

Flexible Heaters

A flexible heater is a heating device that can adjust to any surface. This ensures the best possible contact and heat transmission. Flexible heaters are commonly wrapped around pipes, tanks, drums, and other irregular forms.

Drum Heaters

A drum heater encases liquid drums or gas cylinders to provide heat. Another option is to use drum warmers that connect directly to the drum, such as flexible silicone heaters.

Working of Industrial Heaters

Different industrial heaters have different functioning styles, and a few of the more common ones are listed below:

Immersion heaters work by heating liquids, then immersing goods in the fluid to heat them efficiently.

Other industrial heaters include ovens and furnaces, which work similarly to regular home ovens but on a larger scale.

Outside air enters the heating system via a double-width, double intake, forward curve fan, which blasts the fresh air into a patented burner system that may run on natural gas or propane.

Benefits of Industrial Heaters

They have a robust heat distribution system that can swiftly heat the area.

Flameless heaters do not require much onsite supervision to ensure optimal operation.

Industrial heaters are easy to install and have many applications.

Industrial heaters are effective for a wide range of heating applications.

These heaters are simple to maintain, resulting in a longer lifespan.

Applications of Industrial Heaters

Industrial heaters may be used in a variety of procedures when an object's or process' temperature has to be raised:

Drying heaters are used to dry items or materials throughout the manufacturing process or in batches.

A heat treatment process called annealing is used to treat work-hardened items composed of low-carbon steel. Annealing can be used to soften or stress-relieve a portion completely. A thorough anneal softens the pieces to the point where they can be cold worked without breaking.

Melting Heaters convert solid materials into liquids for further operations (e.g., casting).

Tempering Heaters are used for curing and tempering purposes. They can heat adhesive bonds to cure or set temperatures.

Selecting the Right Industrial Heater Supplier

For the most constructive outcome when purchasing an industrial heater from an industrial heater supplier, it is important to compare several companies using our directory of industrial heater suppliers. Each industrial heater company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly contact them for more information or request a quote. Review each industrial heater business website using our patented website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple industrial heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services