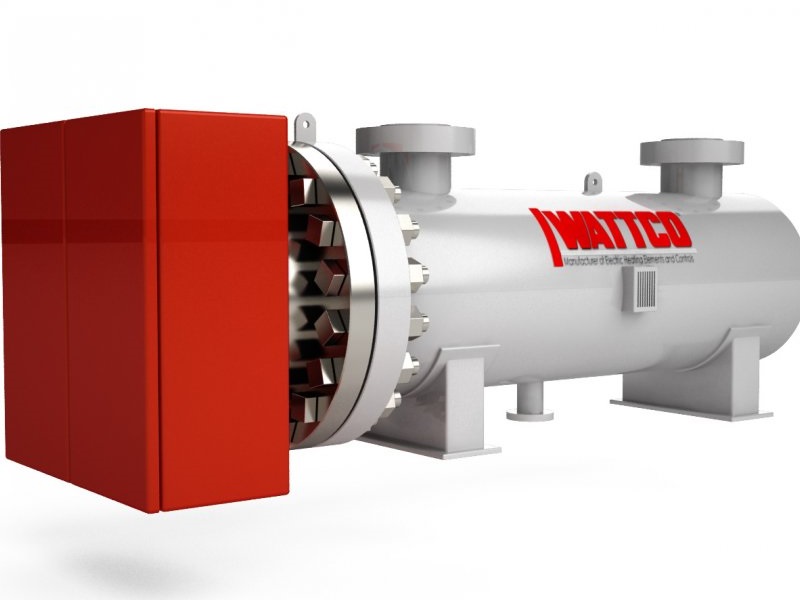

Industrial air heaters are rugged, heavy-duty construction ideal for the most demanding air processing applications. They are dirt, contamination, and vibration resistant, and the optimum sheath material and highest permitted watt densities decrease weight, size, and footprint. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

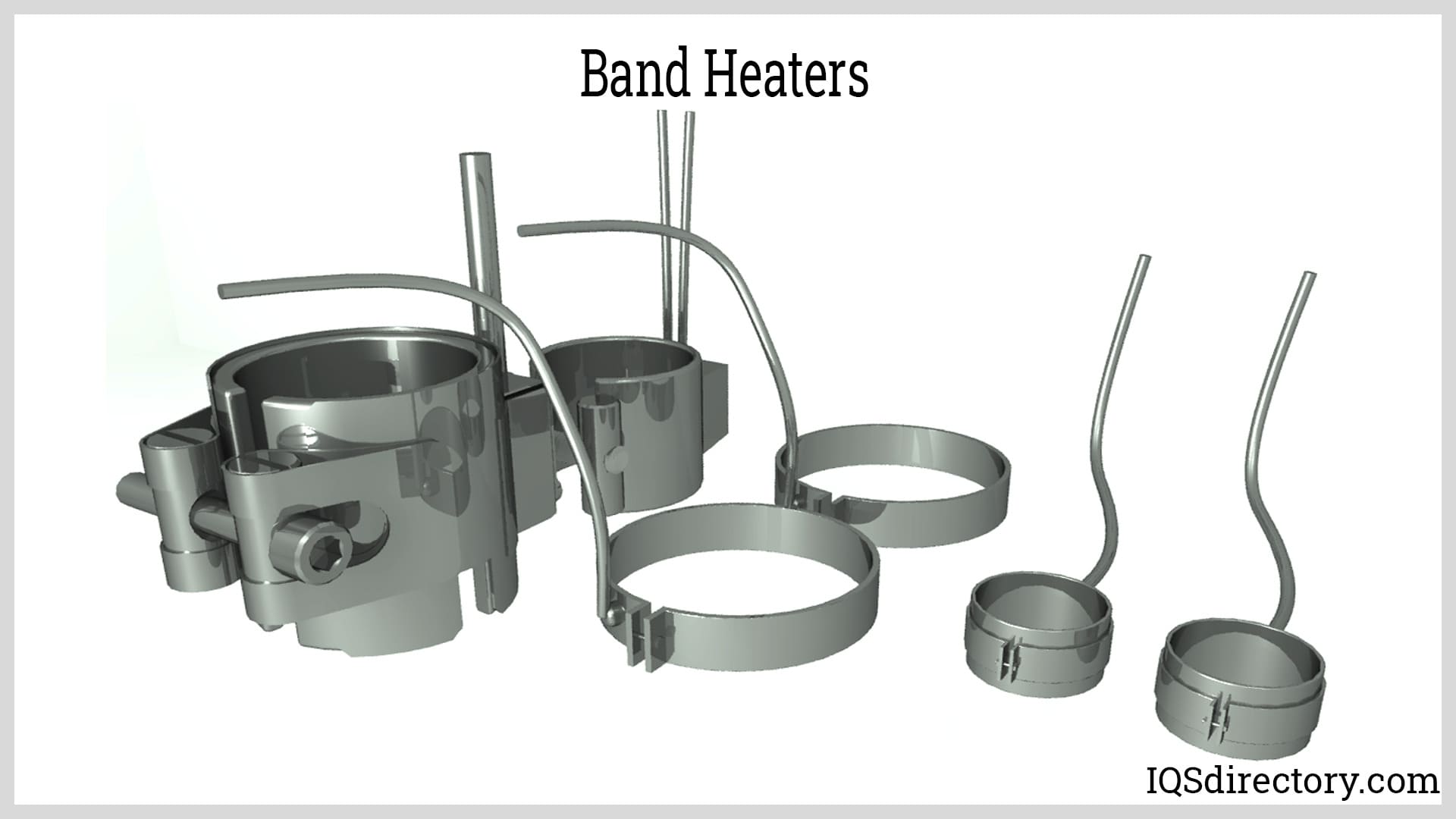

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

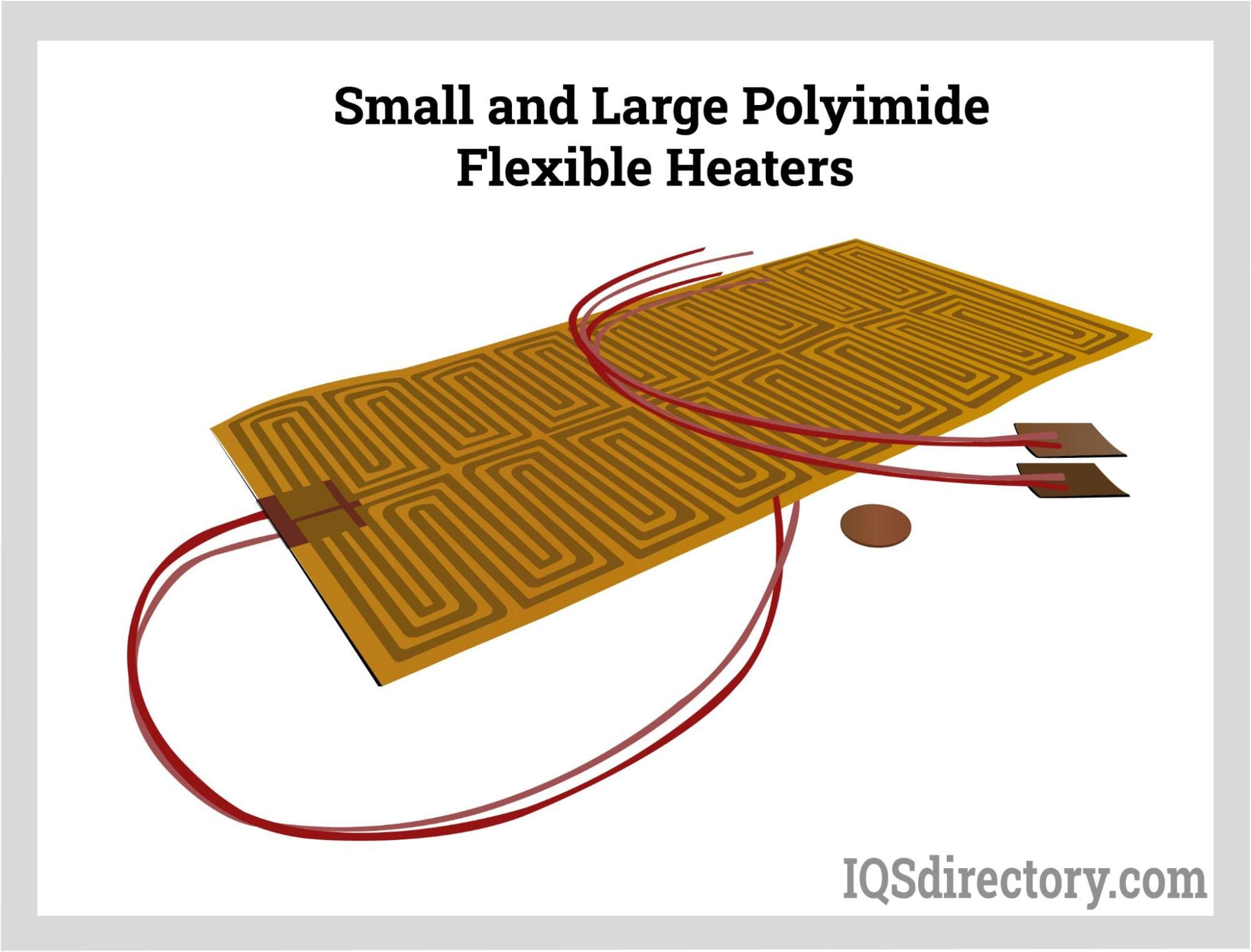

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Air Heater Manufacturers

In an air heater, industrial heat radiates into flowing air or fluid. Dirt, grease, and water in unfiltered air can shorten the life of heaters, especially open coil air heaters. Even after the heater is switched off, a time delay relay will maintain air flowing over the air heating element for some time. An over-temperature sensor can be placed next to the air heater itself if the temperature sensor is far down from the air heating element. Compared to tubular heaters, wire wound heating elements constructed of resistance wire have minimal pressure drop across the heating components.

Salient Features of Air Heaters

- For extended life and corrosion resistance, sheathed heating elements are employed. It's also possible to employ stainless steel-clad heating elements.

- Insulation integrity is guaranteed as recompacted element bends eliminate voids.

- Air heaters for high temperatures can provide up to a 20 W/in² rating and a max outlet temperature of 1200 °F (650 °C).

- Stainless steel element spacers and supports are used to ensure the spacing and avoid drooping.

- High-temperature air heaters have 5 to 300 kW ratings up to 480V.

- The terminal enclosure is thermally insulated, which keeps the wire cool and decreases heat loss.

- Procedure and over-temperature monitoring are possible with integrated sensors.

- C-UL-approved systems are made up to 600VAC, ensuring safe and dependable operation.

- For cool wiring temperatures, air heaters feature an insulated stand-off housing structure.

Material used for Air Heaters

Heating elements with rectangular fins are materials that guarantee maximum heat exchange with a minimal gradient.

All the resistors of an air heater have standardized production with the following characteristics:

- Aluminized steel is used to make rectangular fins.

- A high-quality AISI 321 steel tube acts as a rectangular fins mount.

- Industrial heaters are available in both options, with or without an onboard thermocouple.

- The resistors are assembled with a connection using a zinc-plated steel fitting and terminal blueprints.

Types of Air Heaters

Air heater is a broad phrase that can refer to various heaters.

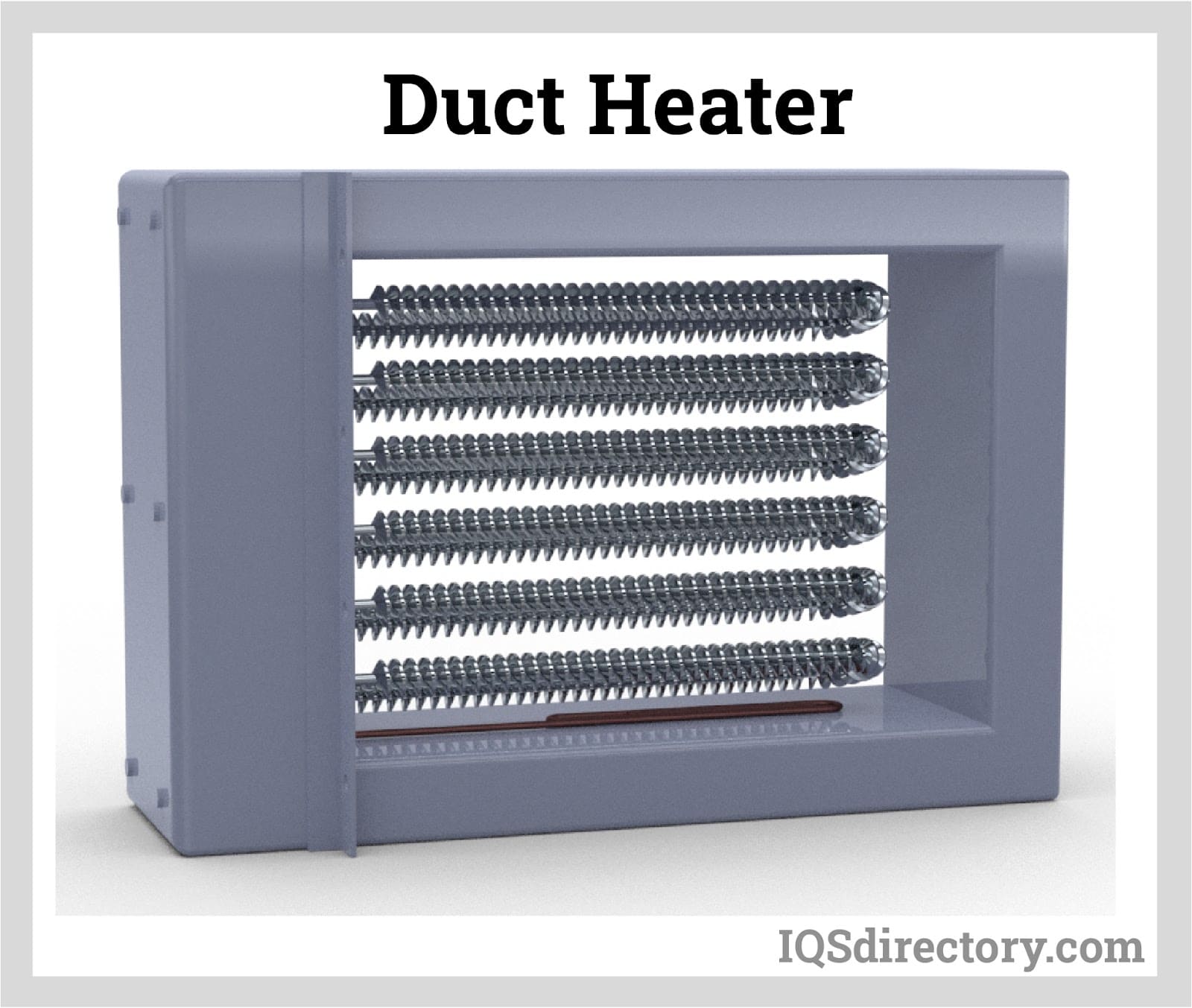

Duct Heaters

Duct heaters work to heat gas streams in continuous movement as the gas passes through the heater.

Forced Air Heaters

These heaters use forced convection to pass air through a heat source with a fan or blower.

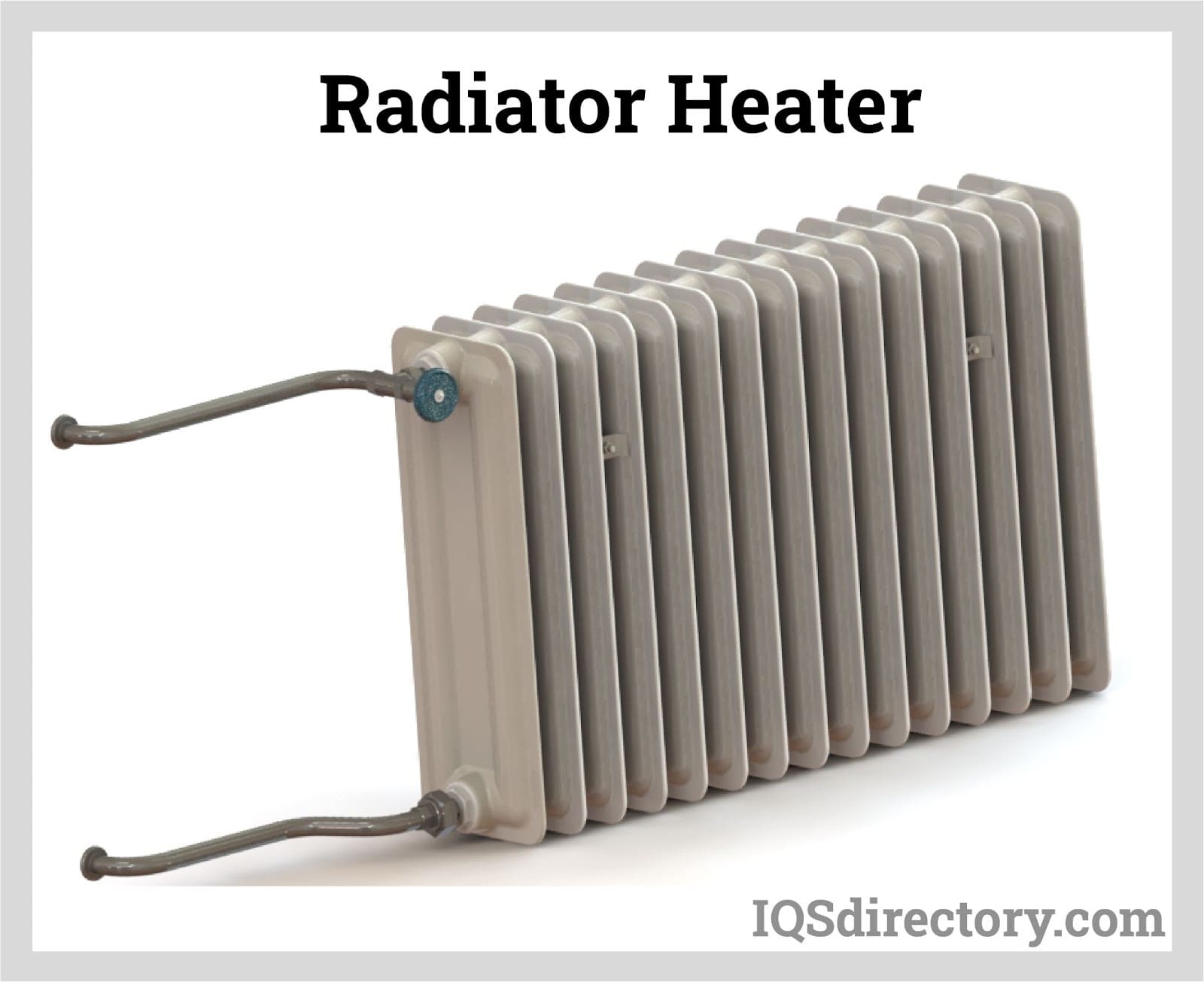

Radiators

Radiators consist of coils that contain circulated and heated media such as hot water, oil, or steam.

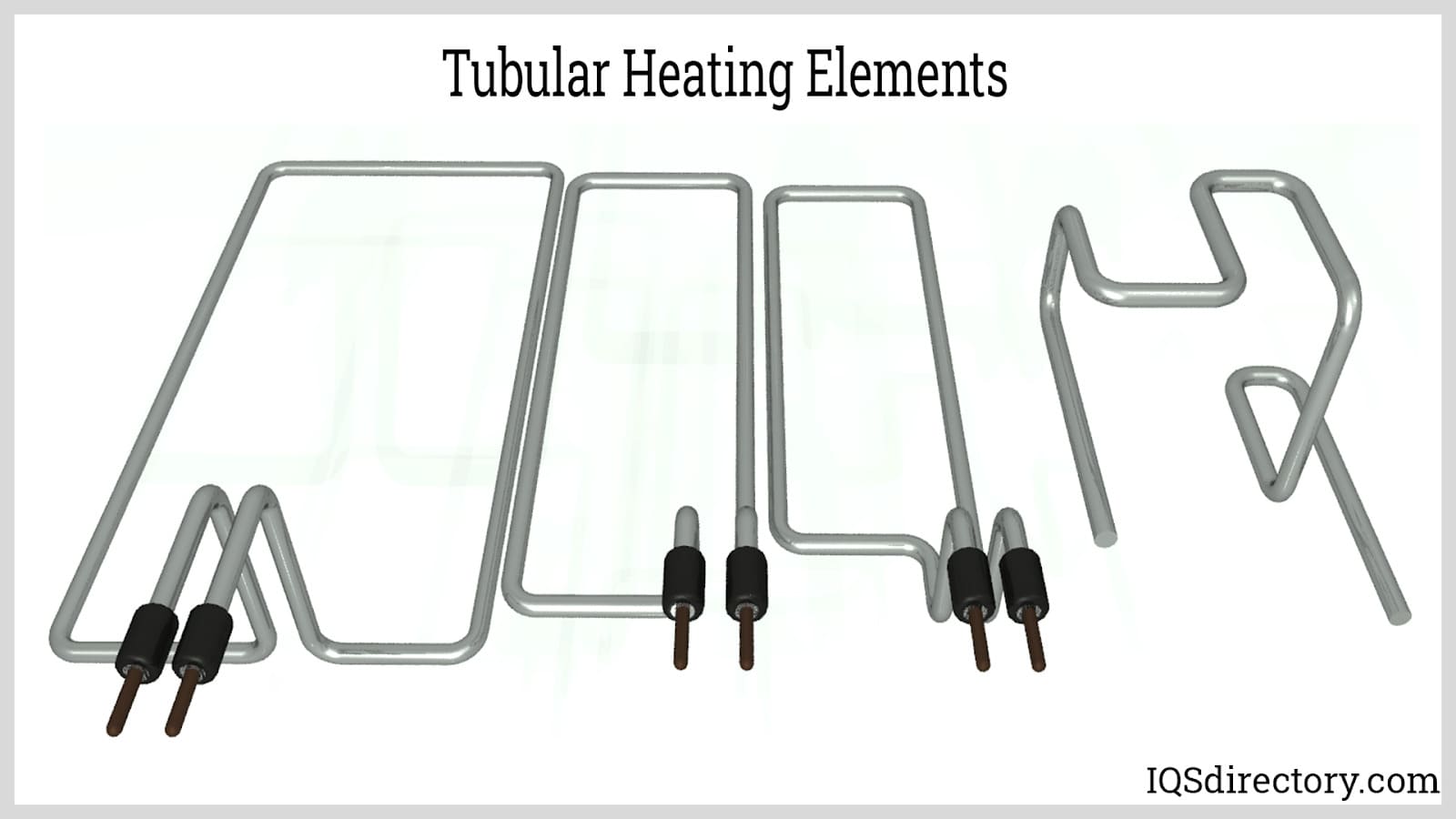

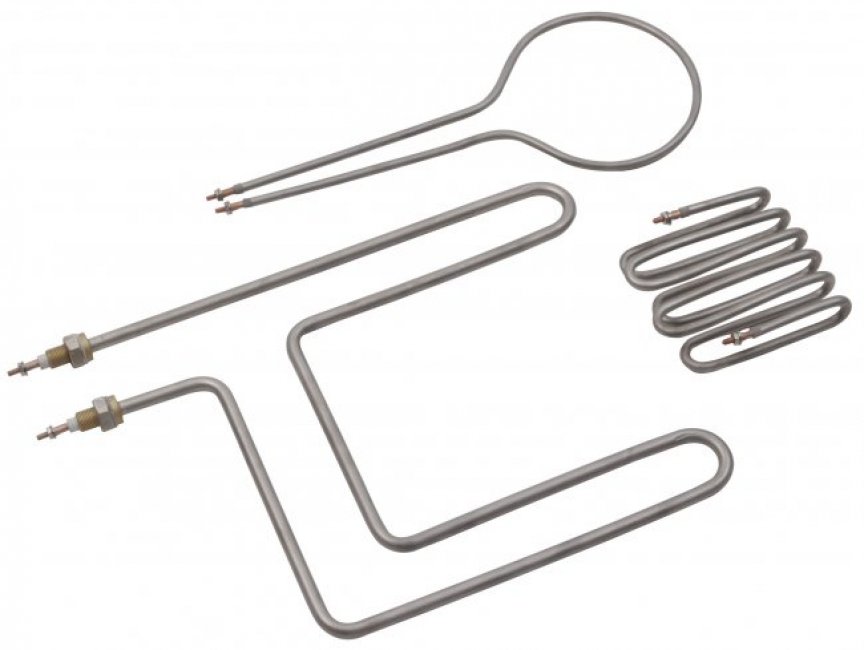

Tubular Heaters

These are typically used in custom heating applications because the element is bendable into custom shapes.

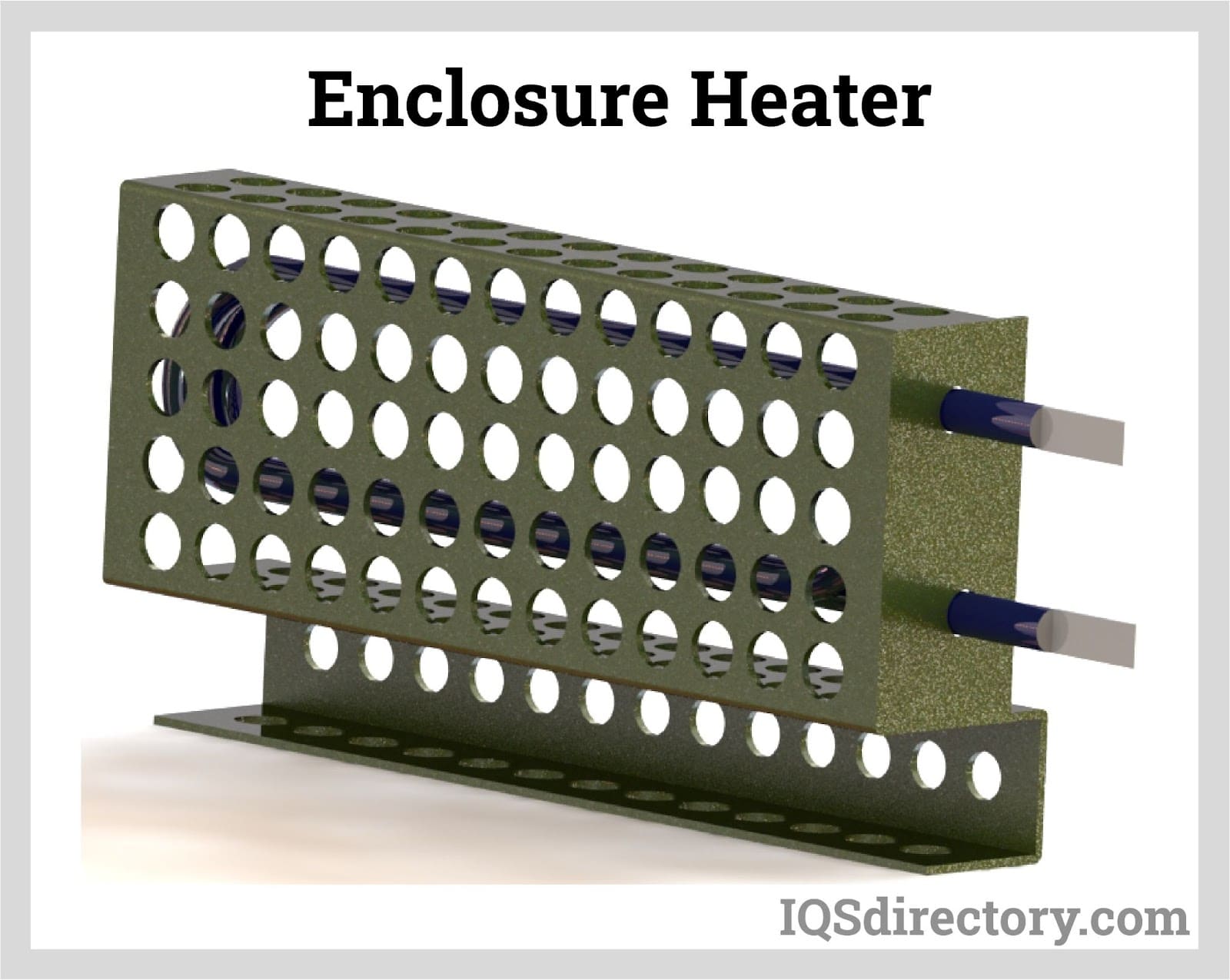

Enclosure Heaters

Enclosure heaters provide humidity control, protection, and freeze control. They are commonly designed to be used in enclosures.

Room Heaters

Safe from emitting noxious fumes or hazardous pollutants, these are used in confined spaces and are generally portable.

Heat Torches

These devices generate a focused flame or stream of abnormally hot air or gas.

Energy Sources of Air Heaters

Electricity, combustible fluids & solids, solar energy, or thermal fluids are the most common energy sources for air heaters.

- Electrically Powered: Electric heaters either use single-phase or three-phase power. They differ in watt density and commonly use AC instead of DC.

- Combustible Fluids and Solids: The fluids used to power air heaters include hydrocarbons. They can be classified as either liquid (diesel, fuel, oil) or gaseous (propane, natural gas). The solids acting as a power source can be wood or wood pallets.

- Solar Energy: Solar energy is a renewable energy source used to power air heaters by applying a solar collector and a thermal mass transfer system.

- Thermal Fluids: These are used to carry thermal energy in air heaters. Steam and hot water are the two most common fluids used in industrial applications.

Applications

Air heaters can be used in various residential, commercial, and industrial situations. HVAC systems and room or space heating are the primary applications for residential and commercial air heaters. Industrial applications include:

- Calcination is a high-temperature heat treatment method for metals, ores, and minerals. The procedure removes hydrates and other impurities from solid materials to change their physical and chemical characteristics.

- Air heaters can be used for preheating processes to prepare unfinished goods and materials for further processing.

- Drying includes evaporation to remove water or other solvents. Inks, raw materials, coatings, and other goods may be dried with air heaters.

- In addition, air heaters are utilized in a wide range of industries, including automotive, rubber, textiles, plastics, electronics, and packaging.

- Air heaters are used in the semiconductor industry for drying wafers and PC boards, preheating process gases, heat shrinking wire insulation, and soldering lead frames.

Choosing the Right Air Heater Supplier

To ensure the most productive outcome when purchasing an air heater from an air heater supplier, it is important to compare several suppliers using our directory of air heater companies. Each air heater company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each air heater business website using our patented website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple air heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services