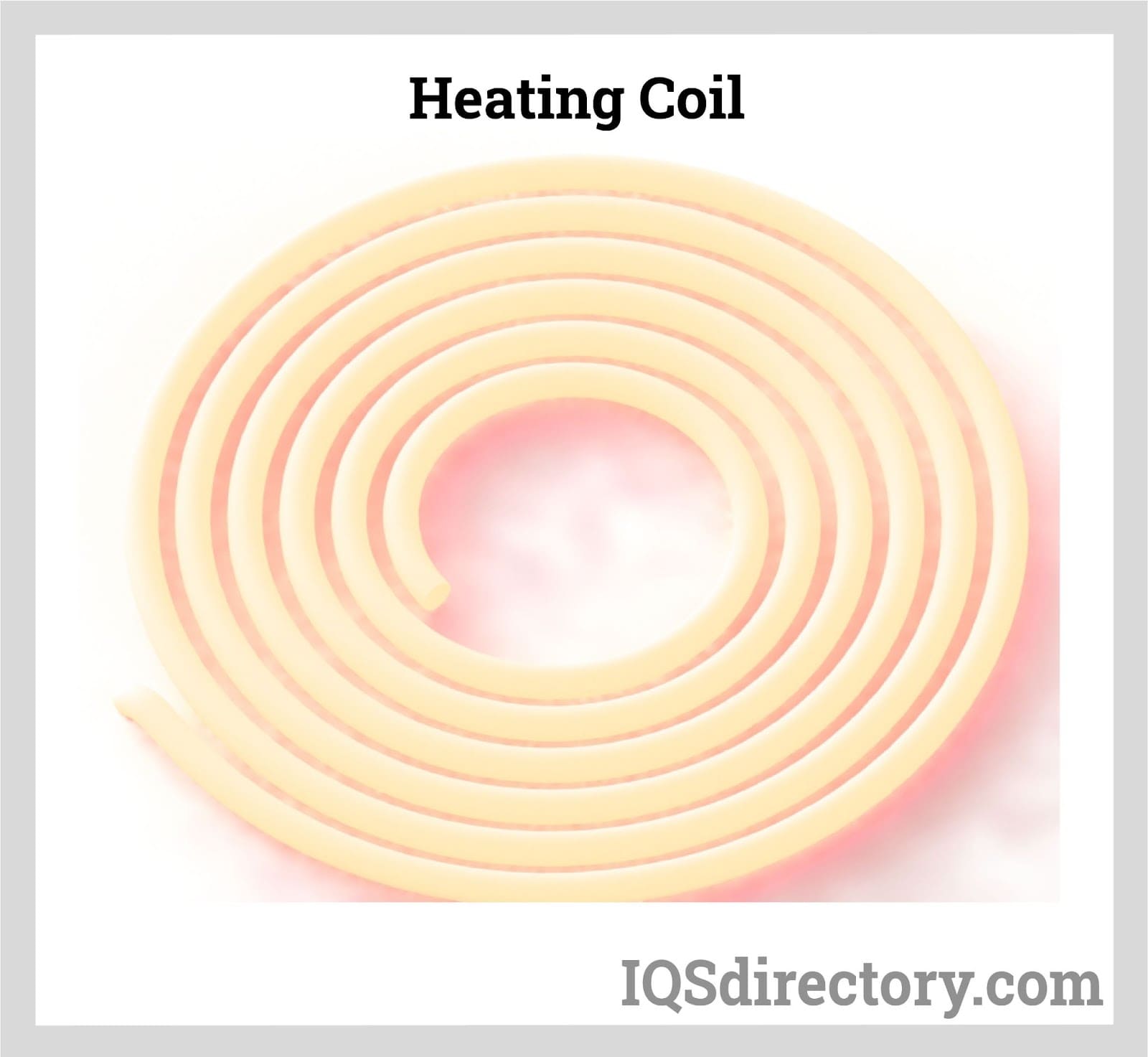

A coil heater is a device that heats water or air using coils. The heater coil operates as a massive resistor in an electric heater, and it heats up when the electric current travels through it. Toasters, space heaters, and other tiny heat-producing equipment are frequently equipped with flat ribbon coils or different heat coil designs, even in the most basic and daily devices. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

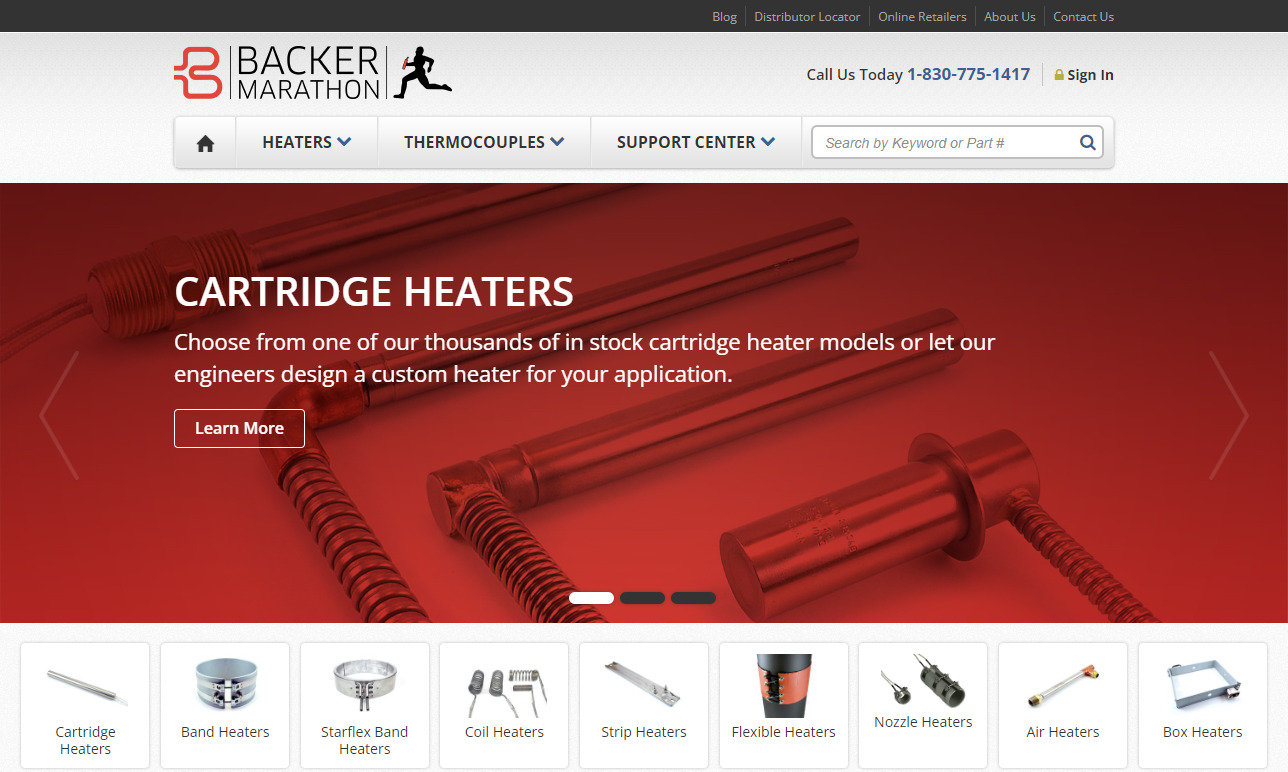

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

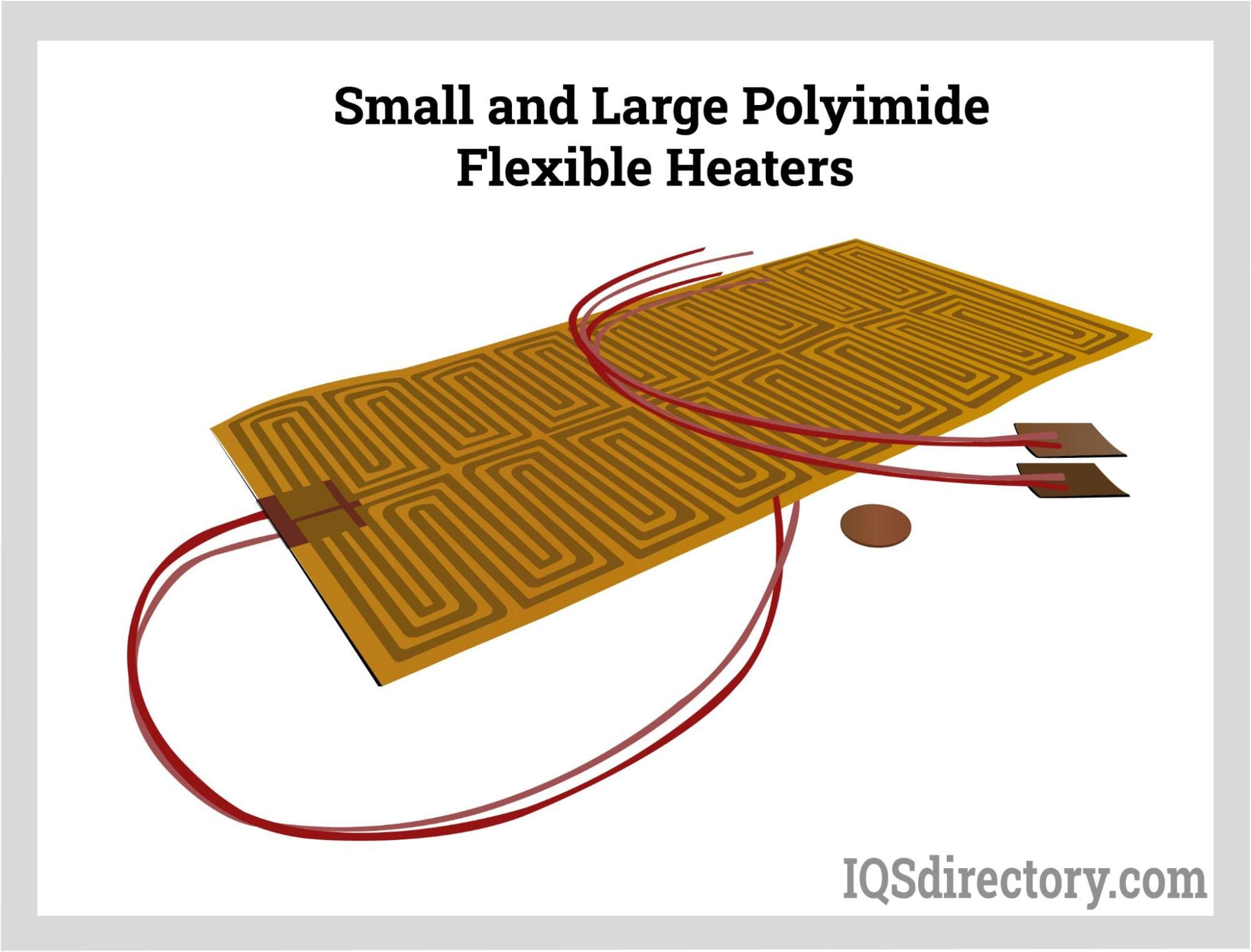

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Coil Heater Manufacturers

Ceramic-coated heat coils may be found in both consumer and commercial ovens; the ceramic layer protects the coils from leaking grease and other contaminants. Heat coils are used as the heat-generating mechanism in clothing dryers, hair dryers, industrial dryers, and many different types of heat generation and moisture removal equipment. Water heaters can utilize heat coils, and furnaces can mix heat coils and air blowers to warm air and then distribute it through ductwork.

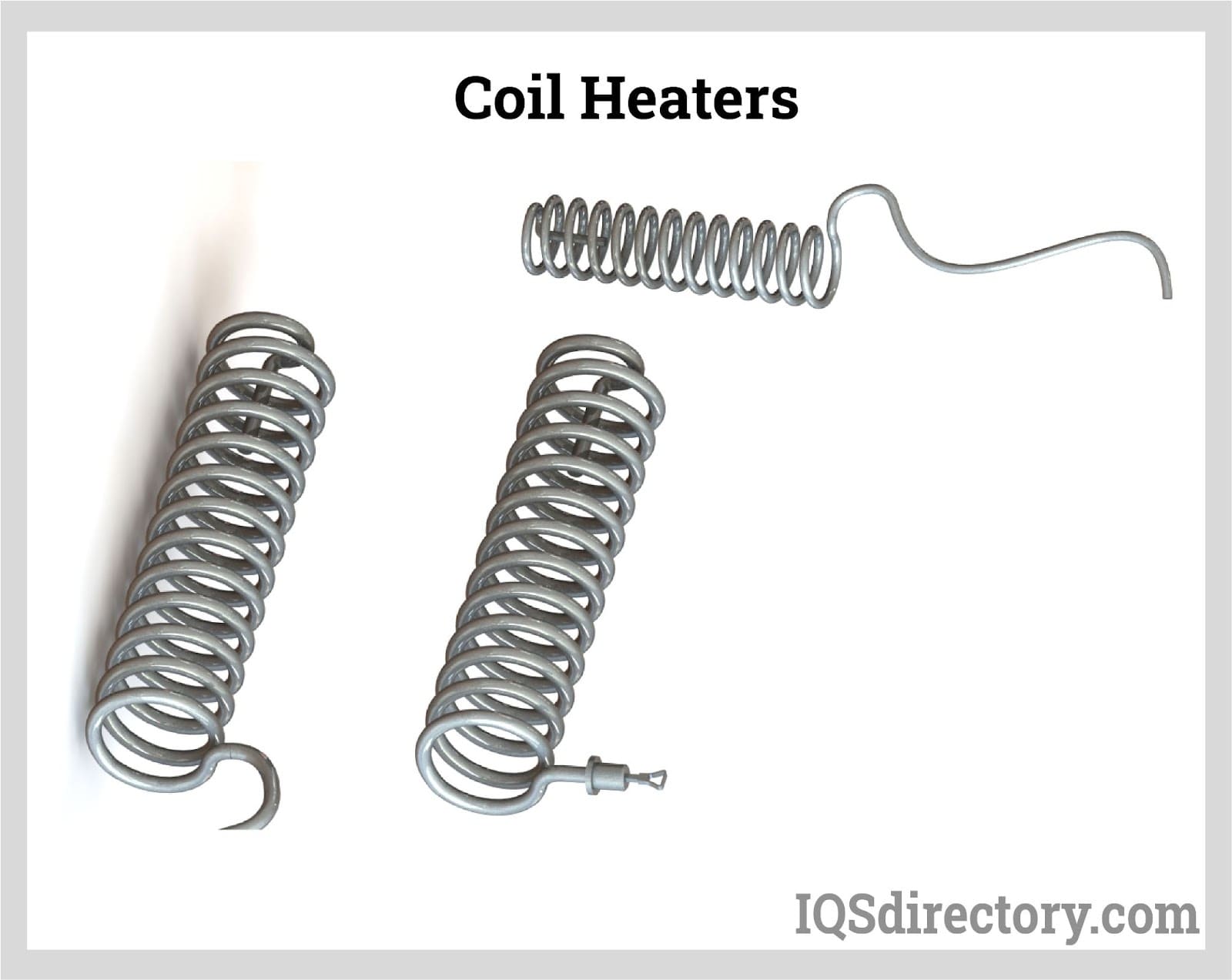

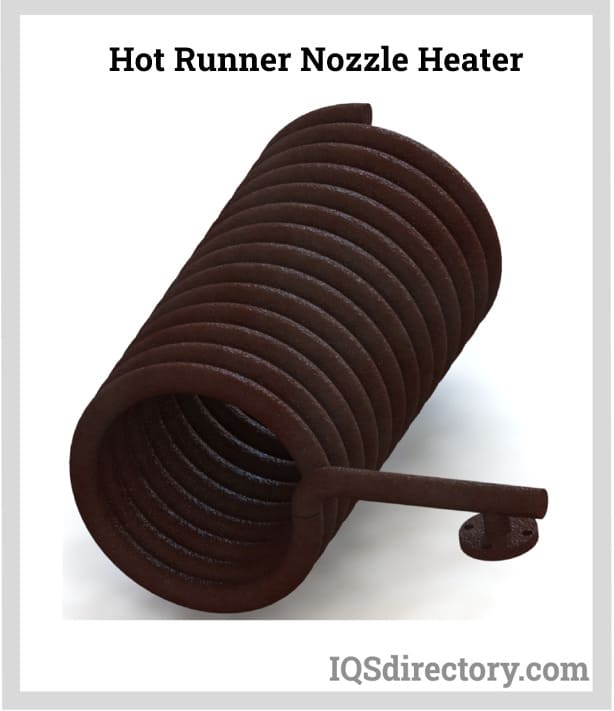

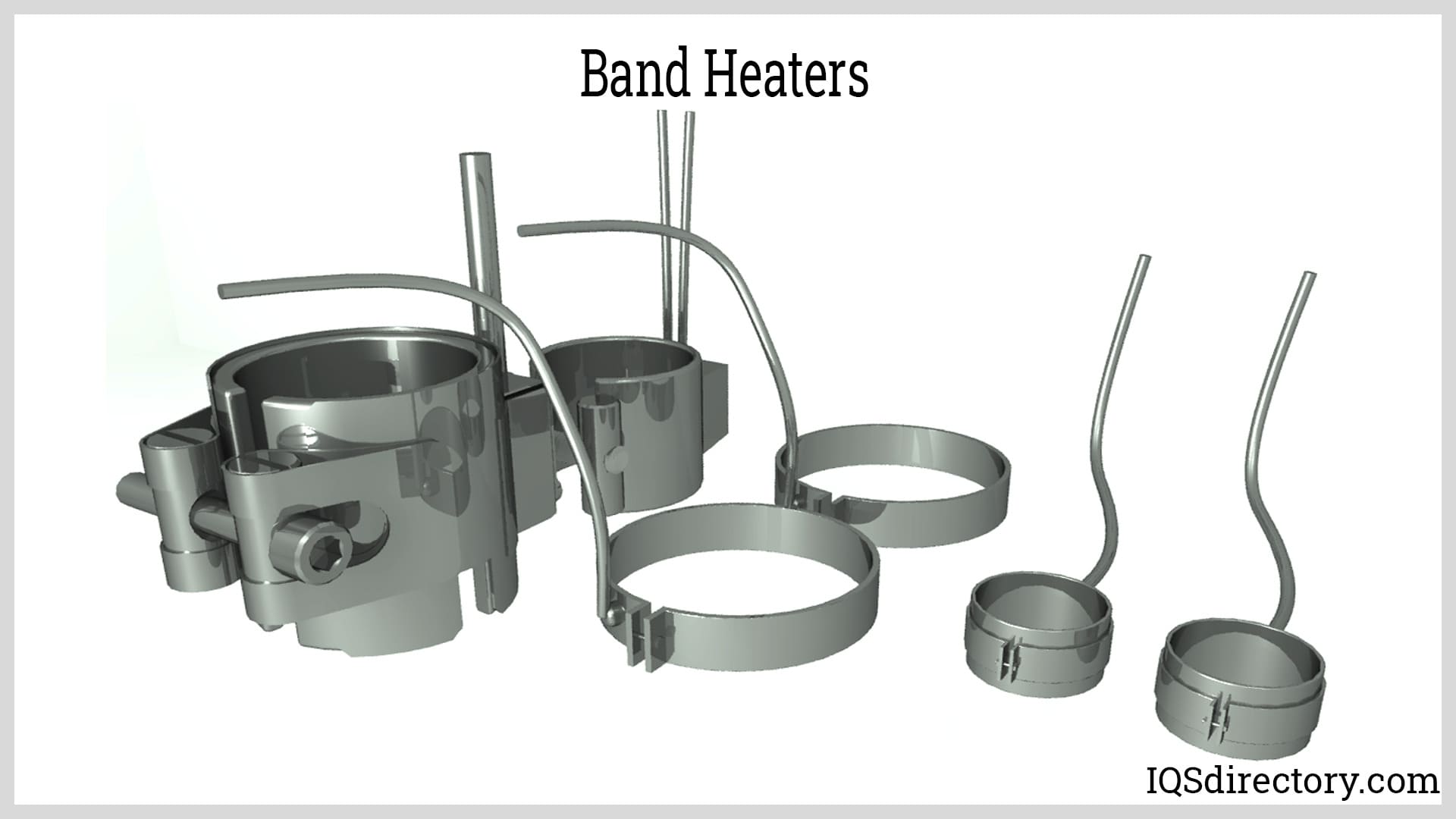

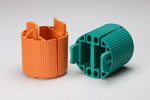

Coil heaters come in flat, round, and micro, the smallest possible size. Maxi is the largest size and the most robust. Some of the forms and sizes offered are low-profile, meaning flat. Some have a lock positioning ring to make installation more accessible, while others are cast in brass for nozzle-to-nozzle applications.

Materials Used in Coil Heaters

- Layered heating elements are used in coil heaters and cable heaters. Heat is generated by resistance wire elements, such as a nickel-chromium alloy.

- They have an annealed exterior with ceramic, mica, or fiberglass insulation and are manufactured of brass, aluminum, nickel, copper, iron, or steel.

- Magnesium oxide, a unique substance that is an excellent heat conductor but a poor electrical conductor, insulates the sheath from the heating element, allowing heat but not electricity to flow from the nichrome. Ceramics, mica, and fiberglass are among other insulation possibilities.

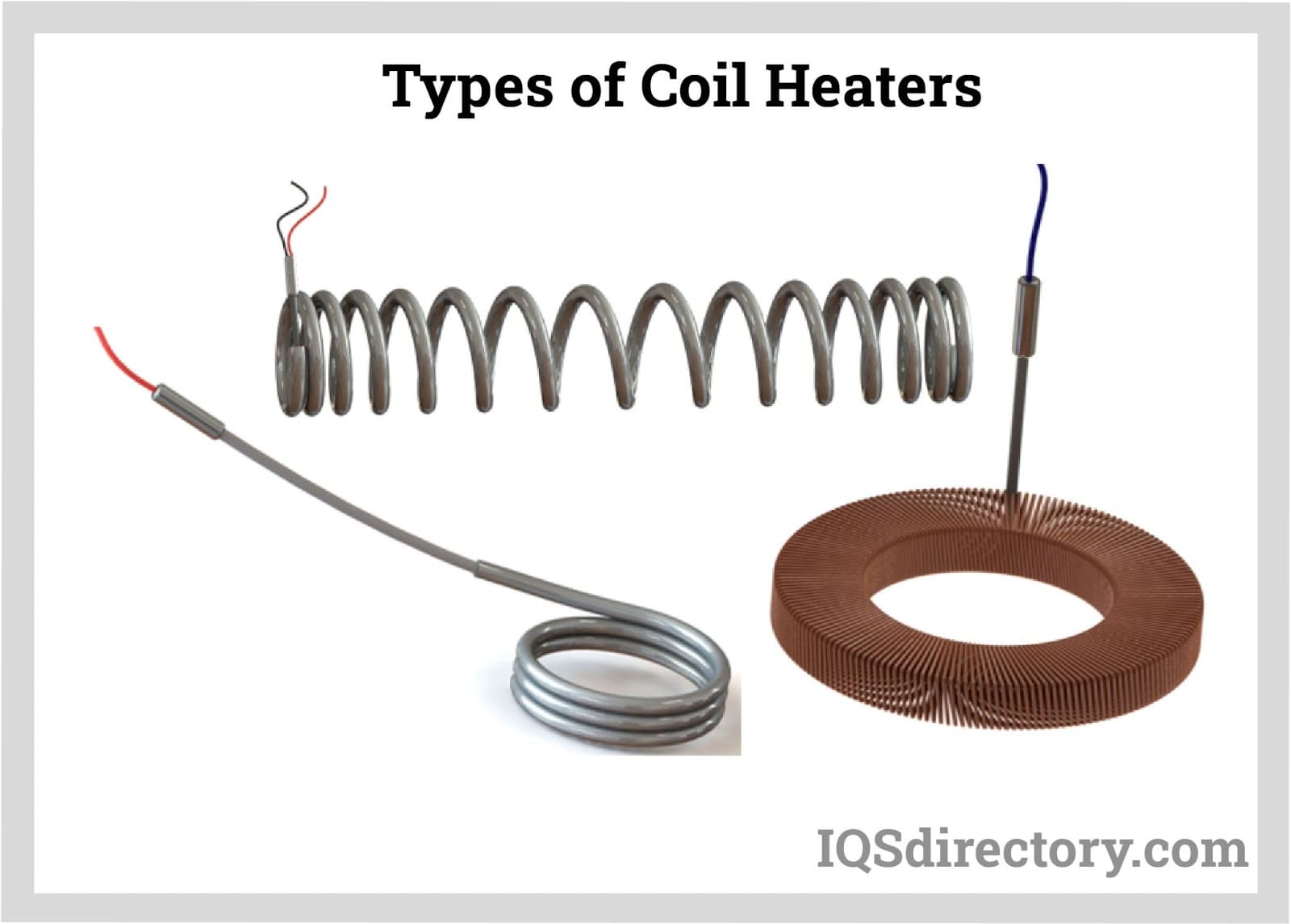

Types of Coil Heaters

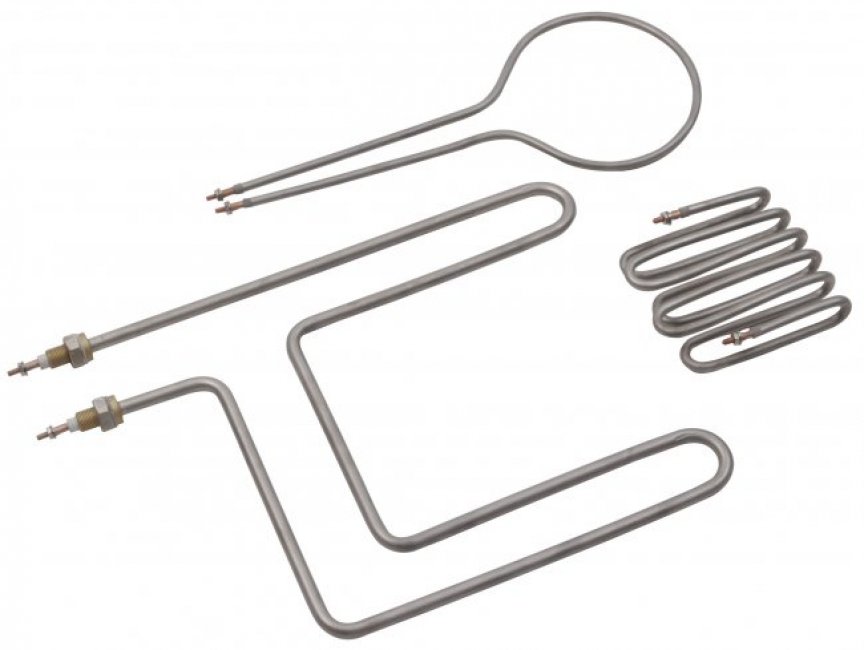

Straight or pre-formed electrical heating components with a metallic sheath are known as coil heaters. They come in various forms and sizes and have a round, square, or rectangular cross-section. Straight, tightly coiled, spiral wound, and star wound cables are examples of coil heater configurations.

Straight Cables

These are utilized to snake through or around various pieces of equipment. The end-user can also shape them for OEM purposes.

Tightly Coiled Cables

These provide the best heat distribution and can contain dispersed watts to focus heat transmission at specific spots.

Spiral Wound

These low-profile heaters create high temperatures in confined spaces.

Star Wound Cables

These are offset coils installed into pipes or ducts to generate a turbulent flow in air or fluid, improving heat transmission.

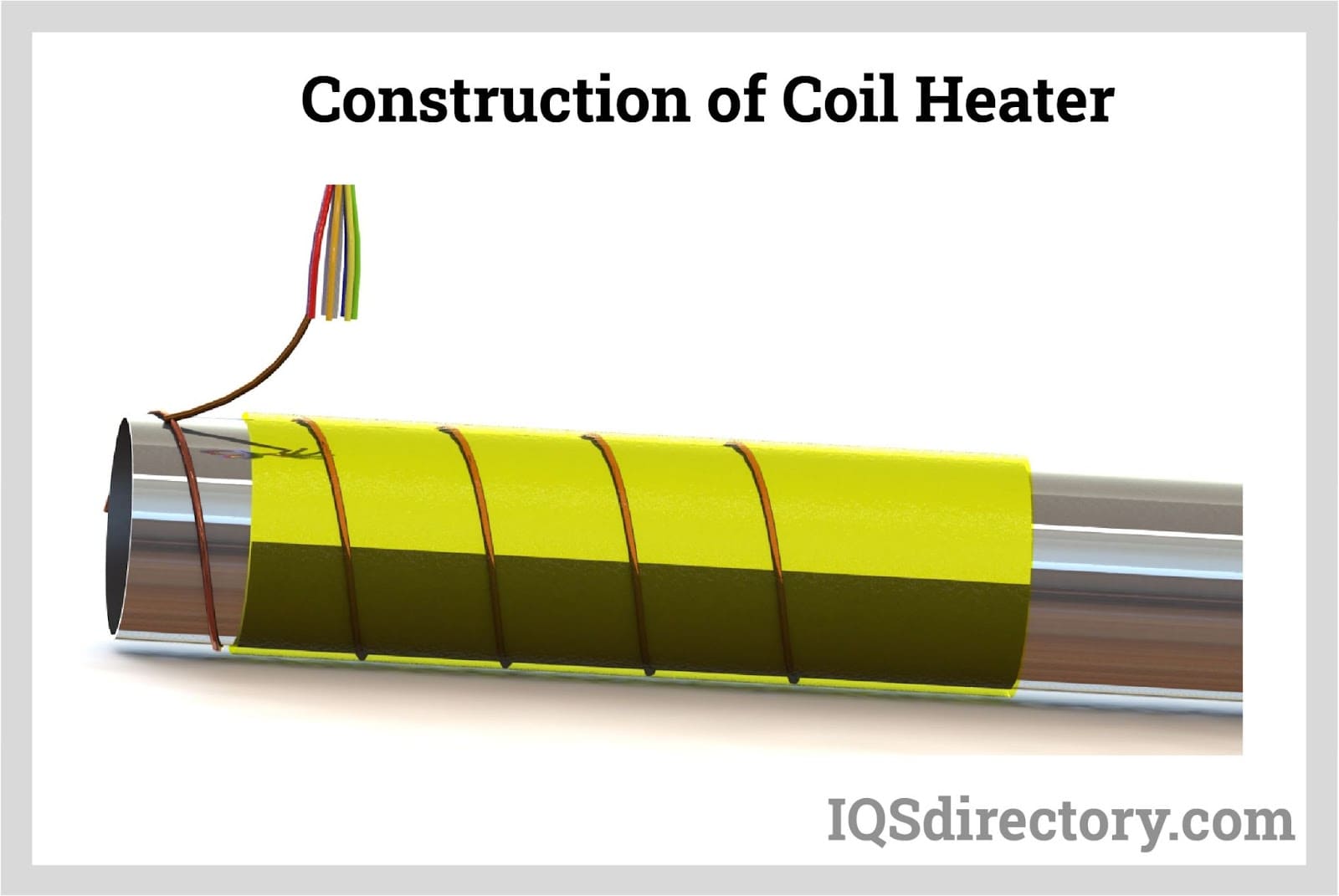

Construction of Coil Heaters

- Most coil and cable heaters work with AC voltages; the required heat voltage is determined first.

- The nickel-chromium wire is then coiled into the chosen shape.

- The heating coil's end is cut as necessary.

- The heat source is connected to the nickel-chromium wire.

- Lastly, the heat source is checked, and the heating coil is secured.

Working of Coil Heaters

- The metal alloy of the wire that goes through the heating coil's core is engineered to have a specified resistance.

- Heat is produced when electricity is transmitted across the wire.

- A high-temperature electrical insulator surrounds the wire, which is then surrounded by a high-temperature metal coating.

- The wire is electrically isolated from the cladding, which is usually grounded. Thus, contacting it will not result in an electric shock.

Benefits of Coil Heaters

Heat Pattern: Coil heaters operate on AC voltages and give a consistent heat pattern over a large area up to 1200 °F (648.9 °C).

Flexible Shapes: Electric coil heaters' excellent flexibility allows them to be formed into practically any shape. As a result, they can be tailored to the application.

Quick Temperature Change: The coil's low bulk facilitates heat transmission during heating and cooling.

Long-lasting: These heaters are simple to maintain. They tend to be exceptionally long-lasting, even with minimum upkeep.

Versatile Use: Electric coil heaters may be utilized in various applications, including liquid immersion, gas heating, and sub-freezing.

Applications of Coil Heaters

- Coil heaters are employed in various sectors, including heating, plastic manufacture, food, textile, and paper.

- Coil heaters, which come in various shapes and sizes, including round, spiral, and spiral-wrapped, may be bent to a particular size or form and are utilized when high temperatures are required in restricted spaces.

- Star coiled coils are put in pipelines and ducts to generate a turbulent flow in air or liquid.

- Coil warmers are used in holding tanks, blow molding machines, extruders, bag sealing, and hot metal forming punches.

- Some coil heaters are corrosion-resistant and can be submerged in hot substances or utilized in cryogenic applications, depending on the metal.

- These heaters have been effectively employed as vital heating cells in hot-runner nozzles for plastic injection molding.

Selecting the Correct Coil Heater Manufacturer

To ensure you have the most positive outcome when purchasing coil heaters from a coil heater company, it is important to compare several manufacturers using our directory or coil heater manufacturers. Each coil heater manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each coil heater business website using our proprietary website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple coil heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

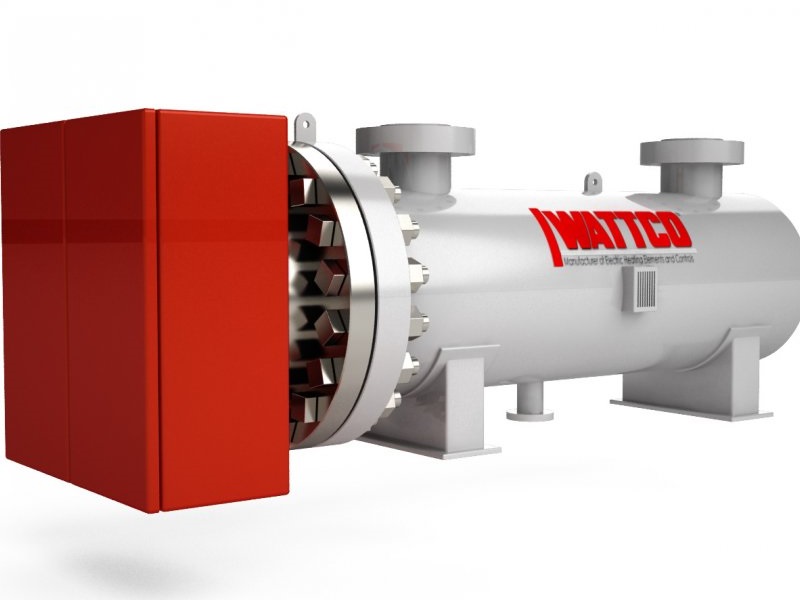

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services