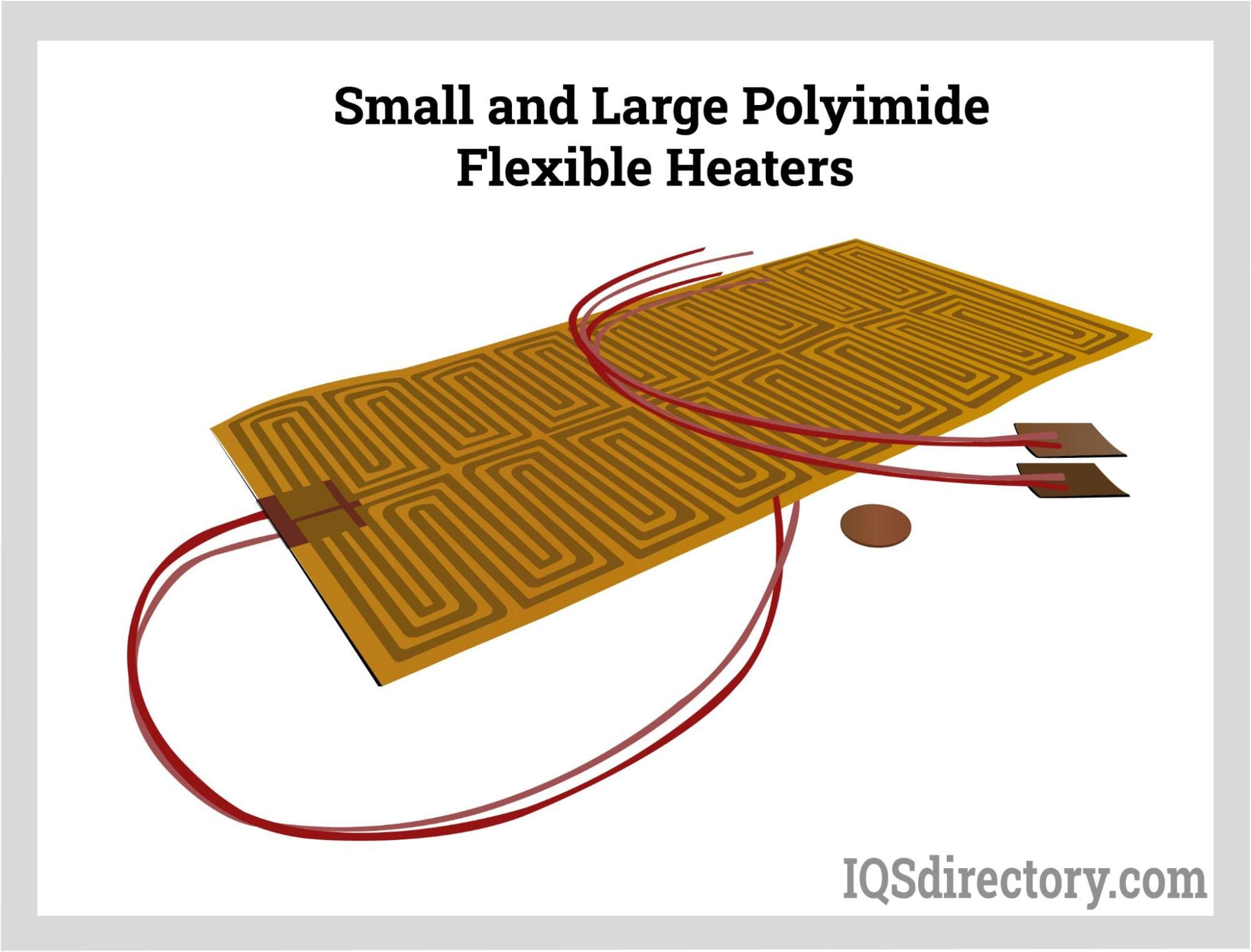

Silicone heaters are rugged, durable, efficient, and resistant to moisture and chemicals. They may be glued or attached to any surface or other system component with ease. Surface heaters are used in various industrial, commercial, and military applications where dependability, cost-effectiveness, minimal cross-section, degradation resistance, and fundamental flexibility are important. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

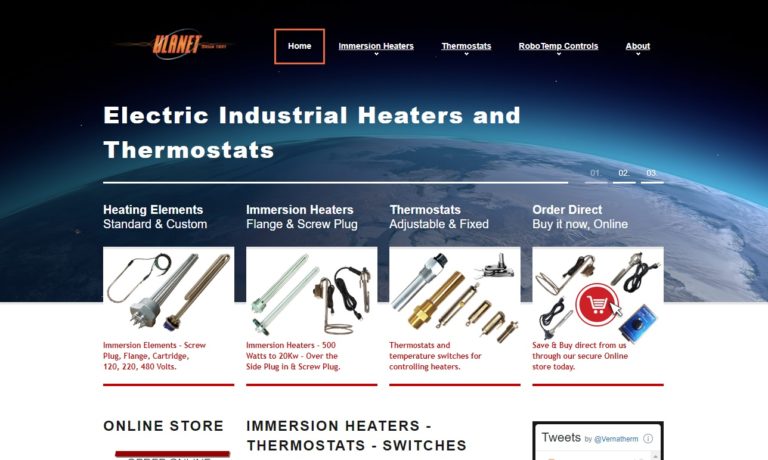

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

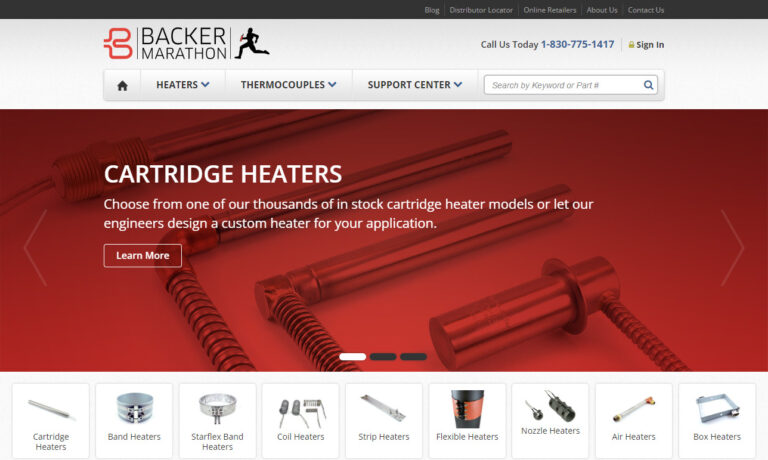

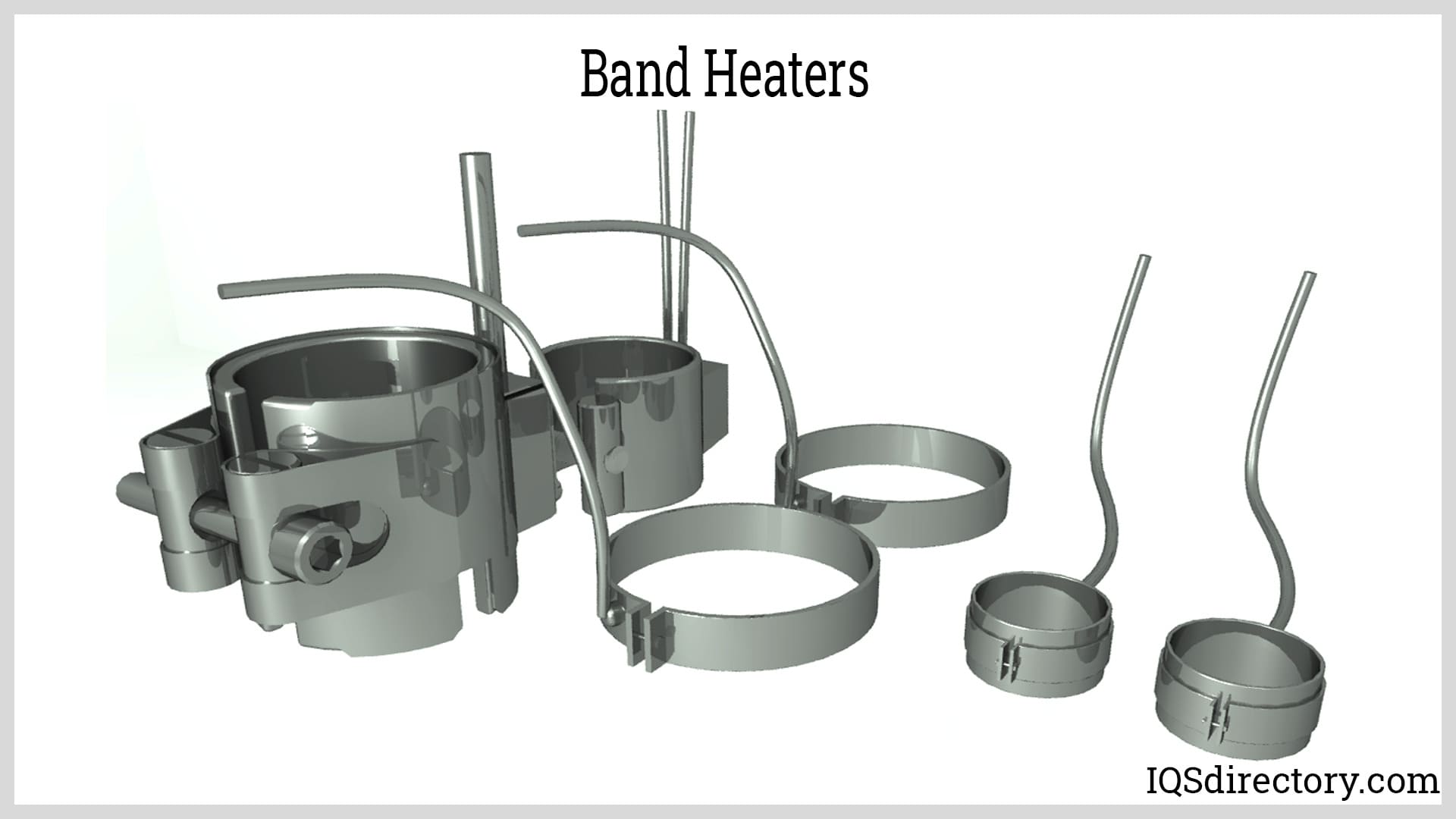

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Silicone Heater Manufacturers

The etched or wire circuit is soldered to the power leads, then vulcanized between two layers of silicone rubber to create a homogeneous device. The silicone provides physical protection against scraping and scuffing and acts as a moisture barrier to allow operation in damp and outdoor situations. Silicone is chemically resistant as well.

Salient Features

- Silicone Heating Pads can be manufactured for various amperes or wattages with a maximum watt density of 60 W/in².

- Silicone heaters are heat-transfer efficient and have tight tolerances, and they can work in temperatures as low as -76 °F (-60 °C) and as high as 446°F (230 °C).

- Thermostats to measure temperature can be attached to silicone heating pads, temporarily or permanently.

- Silicone heating pads can be strapped, clamped, magnetized momentarily, or permanently vulcanized to cylindrical components in the factory.

- These have a wattage tolerance of ±10%.

- The dielectric strength of a Silicone Heating Pad is 1000 VAC.

- They are constructed with wire-wound or etched-foil elements.

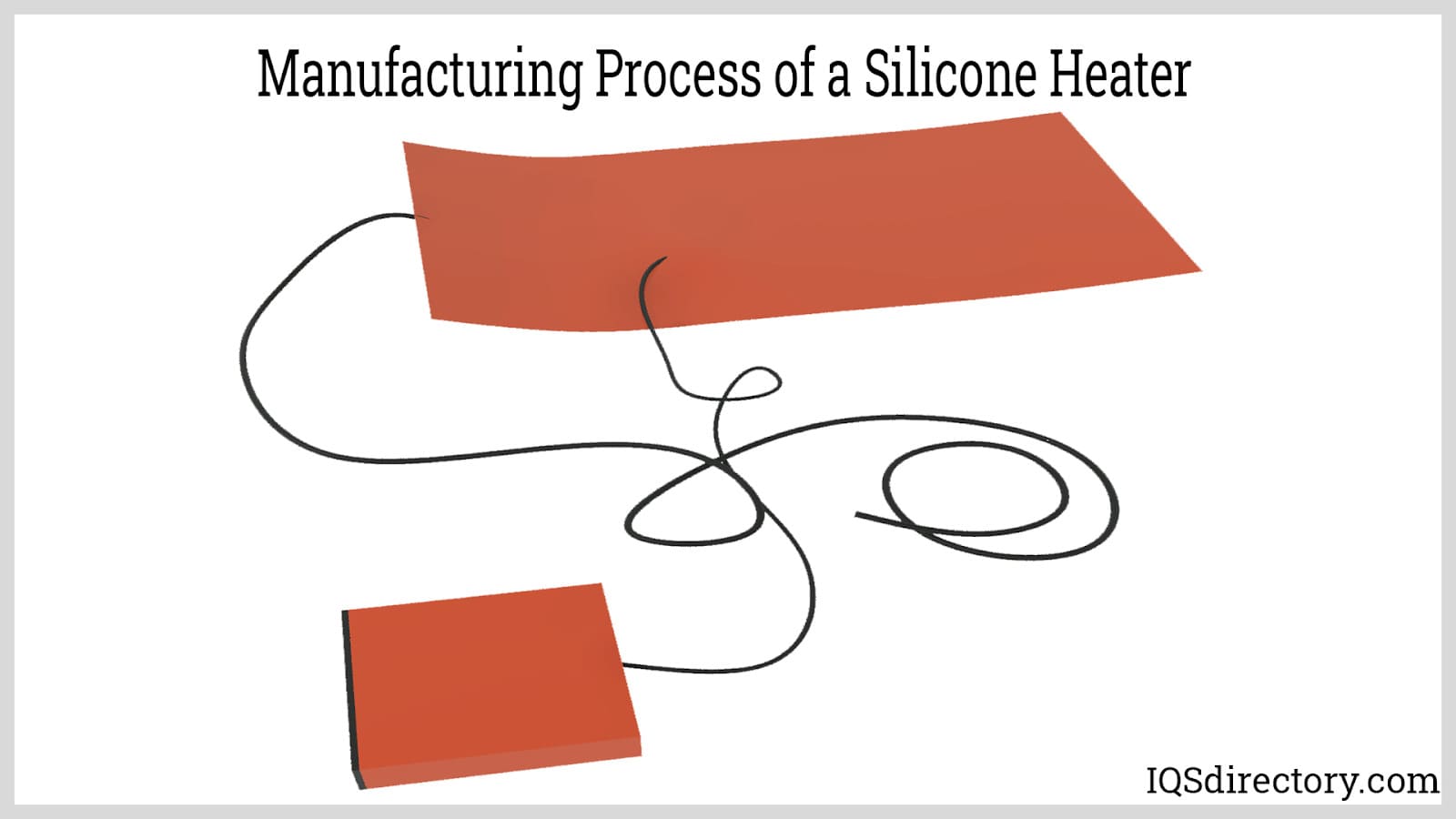

Manufacturing Process of a Silicone Heater

The manufacturing process of a silicone heater consists of the following steps:

- First, the texture of the silicone material is chosen; this can either be smooth or rough, depending on flexibility and texture.

- Based on silicone rubber heater technology, the lengths of the flexible heater are coiled like a telephone cord.

- The lead wires are supported structurally by the molded end protector, which clamps around a pipe.

- To prevent condensation and contamination in the wafer process, it is crucial to have a consistent gas temperature in the supply lines.

- A cylinder-shaped piece that "snaps" into a pipe of the same diameter is a common design.

- Multiple layers can be applied for a thicker heater application.

Material Used in a Silicone Heater

The materials used in a fiberglass/silicone heater depend upon the type of element used. The wire-wound element contains different types of resistance wire:

Nickel Chrome

These alloys are non-magnetic with high resistivity and good oxidation resistance. These have a maximum temperature of up to 2280 °F (1248.9 °C).

Iron Chrome Aluminum

These alloys are high-resistance materials with very good form stability. They provide longer element life, have higher surface loading capabilities, and lower density.

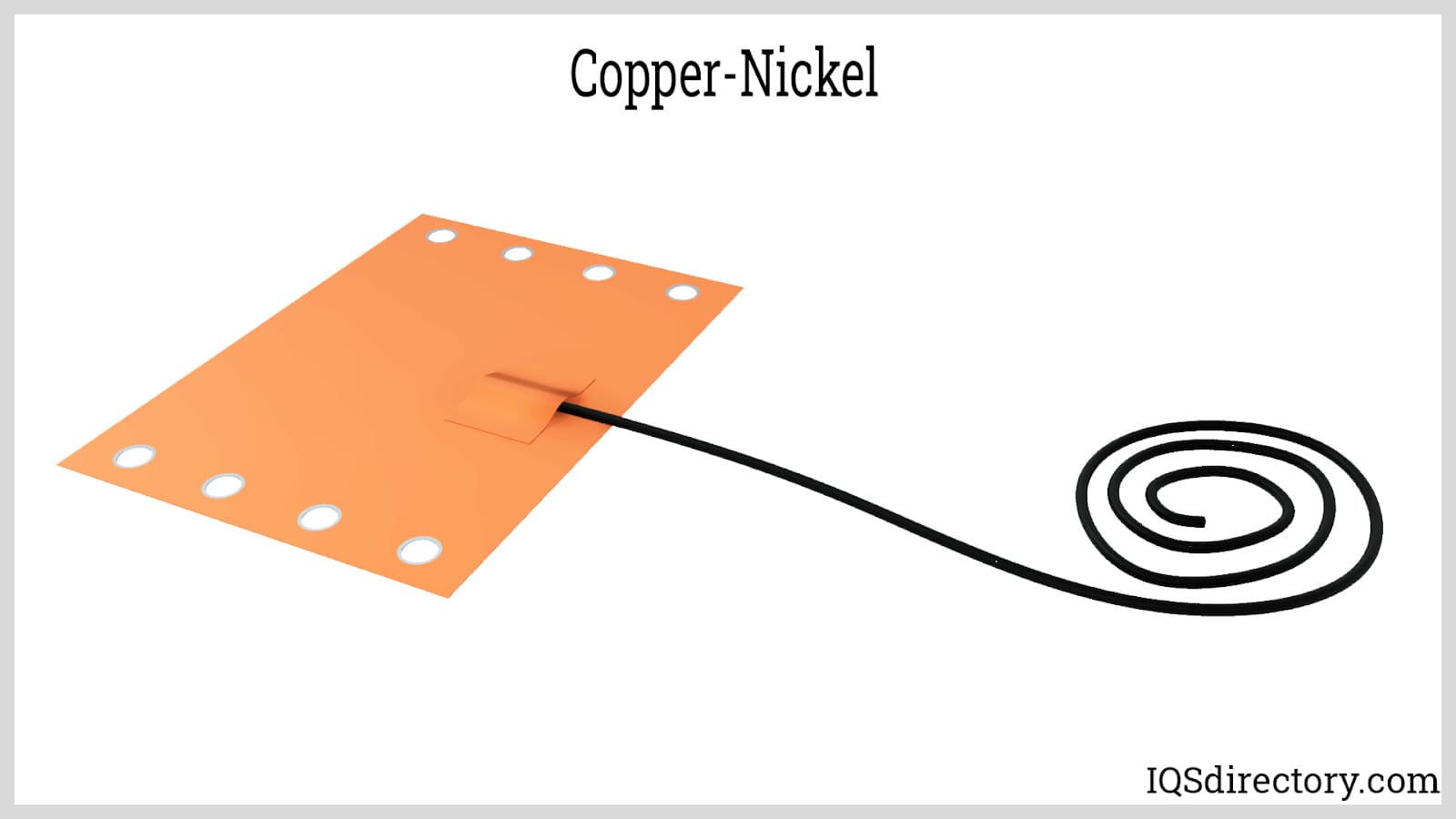

Copper-Nickel

These alloys have a low-temperature coefficient of resistance and a medium range of electrical resistivity.

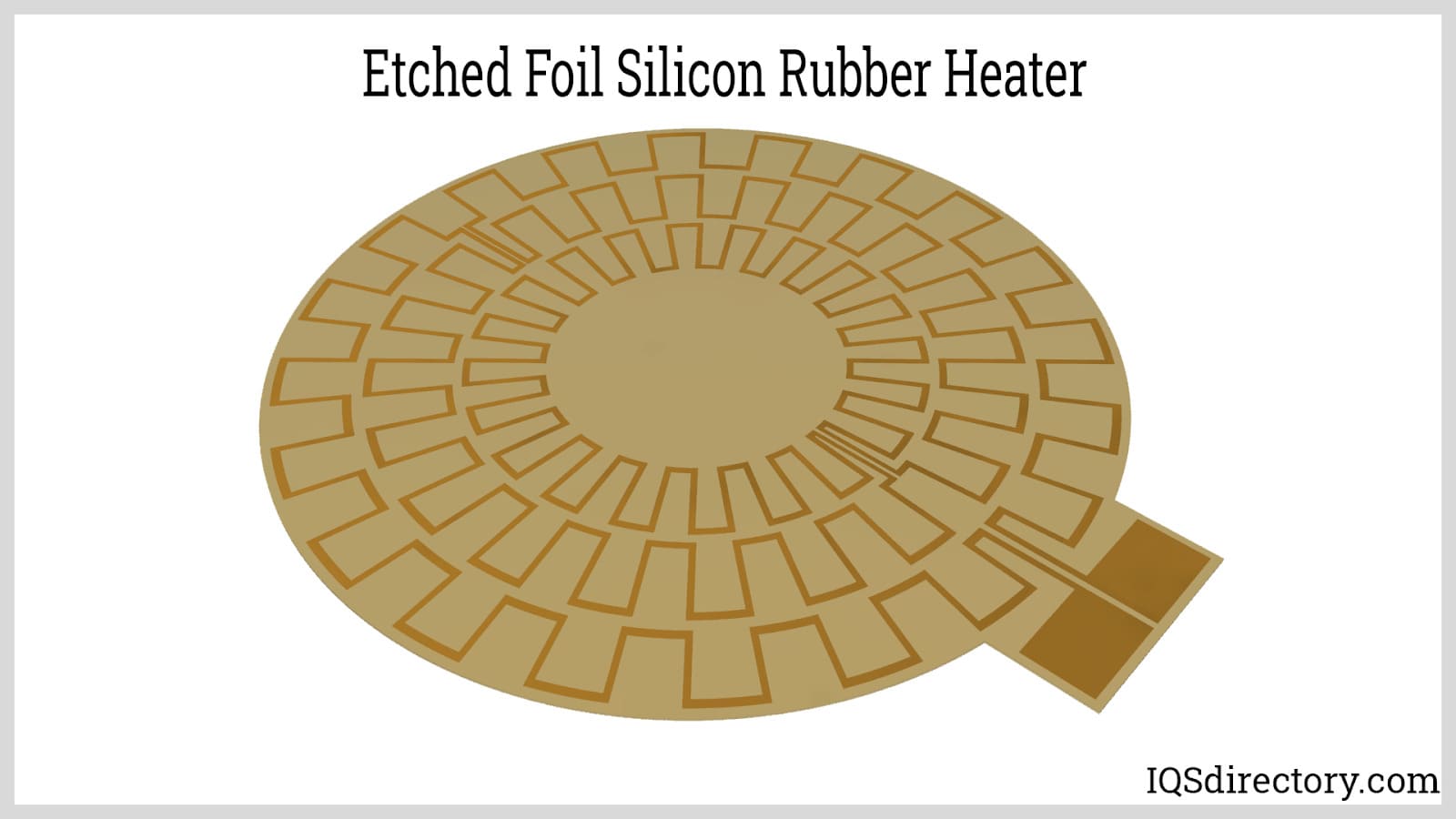

The etched-foil elements contain the following materials:

- Chemically etched circuits laminated between thin sheets of silicone

- Traditional print/etch technology

- Alloys such as stainless steel, aluminum, non-magnetic alloys, constantan, copper, nickel-chrome, or others

Circuit Design for Rapid Heating

- Resistance wire is glued to the silicone rubber in wire-wound silicone rubber heaters to guarantee physical robustness and uniform heat distribution.

- Chemically etched circuits are sandwiched between thin silicone sheets to guarantee rapid heat transmission in the etched foil silicone flexible heaters.

- When combined with temperature control devices, silicone rubber flexible heater create high output voltage, assure even heat distribution, and provide improved temperature control.

- Silicone heaters have a watt density of 30 watts per square inch and may be built as thin as 0.020 inches (0.5mm). They can resist 750 volts. As a result, silicone heaters are capable of quick thermal recovery and even heat distribution.

- The temperature range of these heaters is -40 °F (-40 °C) to 392 °F (200 °C), so they are suited for cryogenic and high-temperature applications.

Applications of Silicone Heaters

Silicone rubber heating elements are used in various applications owing to their benefits to industrial, commercial, and military applications. Here are some Industrial application areas:

Protect liquids and viscous materials from cold temperature: Silicone rubber can adhere to the walls of metal condensation tanks to keep liquids and viscous materials above the freezing point.

Prevent condensation: Silicone rubber heaters may be used to prevent condensation in any enclosed environment.

Prevent corrosion: Silicone rubber heaters can be attached to the inside walls of tanks or hoppers to keep the surface temperature above the point at which moisture forms.

Other areas include:

- Electronics

- Telecommunications equipment

- 3D printing

- Aerospace manufacturing

- Food processing and storage

Choosing the Correct Silicone Heater Supplier

To ensure the most positive outcome when purchasing a silicone heater from a silicone heater supplier, it is important to compare several businesses using our directory of silicone heater companies. Each silicone heater supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each silicone heater business website using our patented website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple silicone heater companies with the same form.

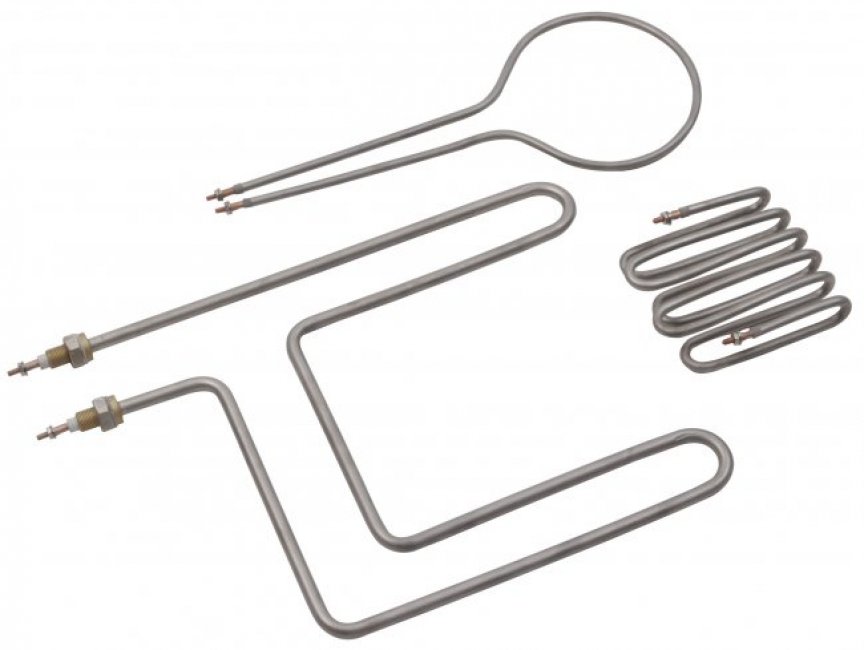

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

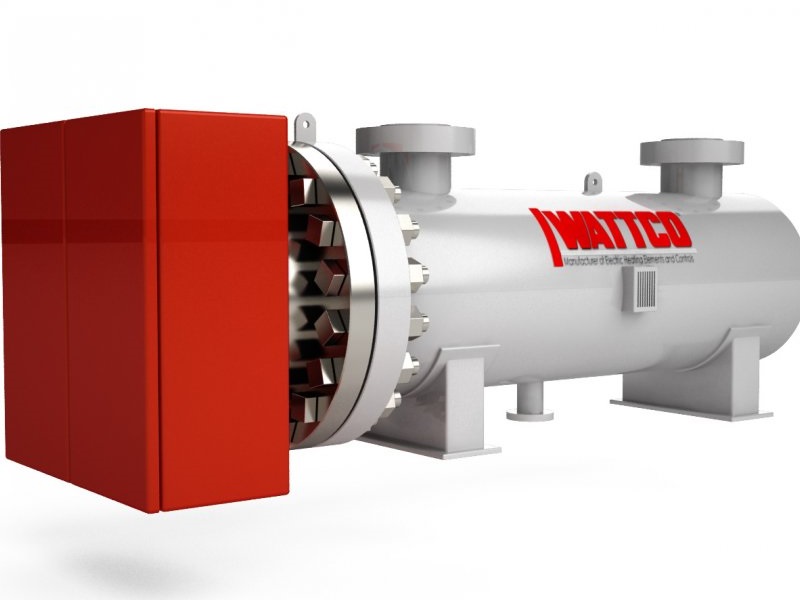

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services