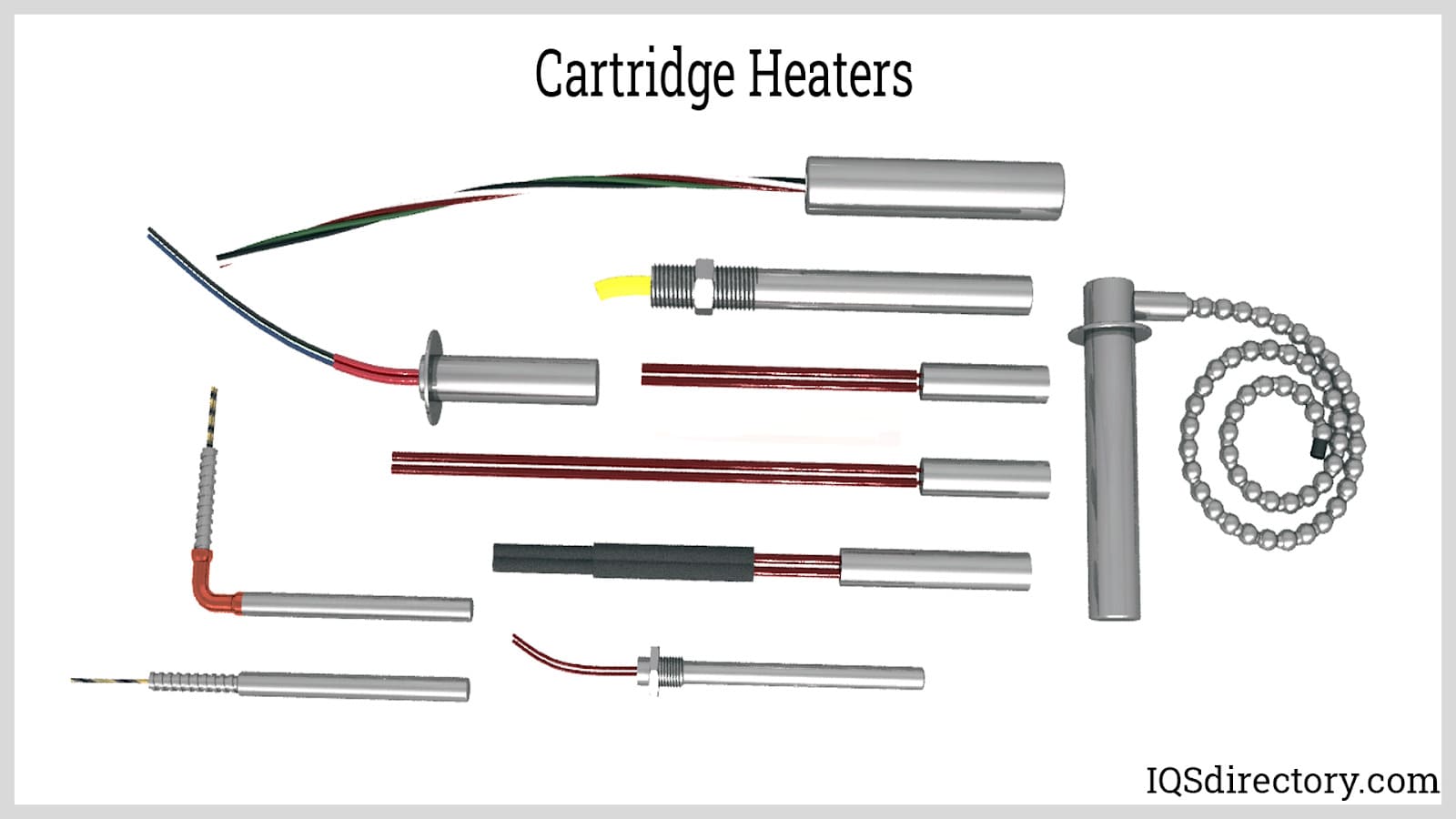

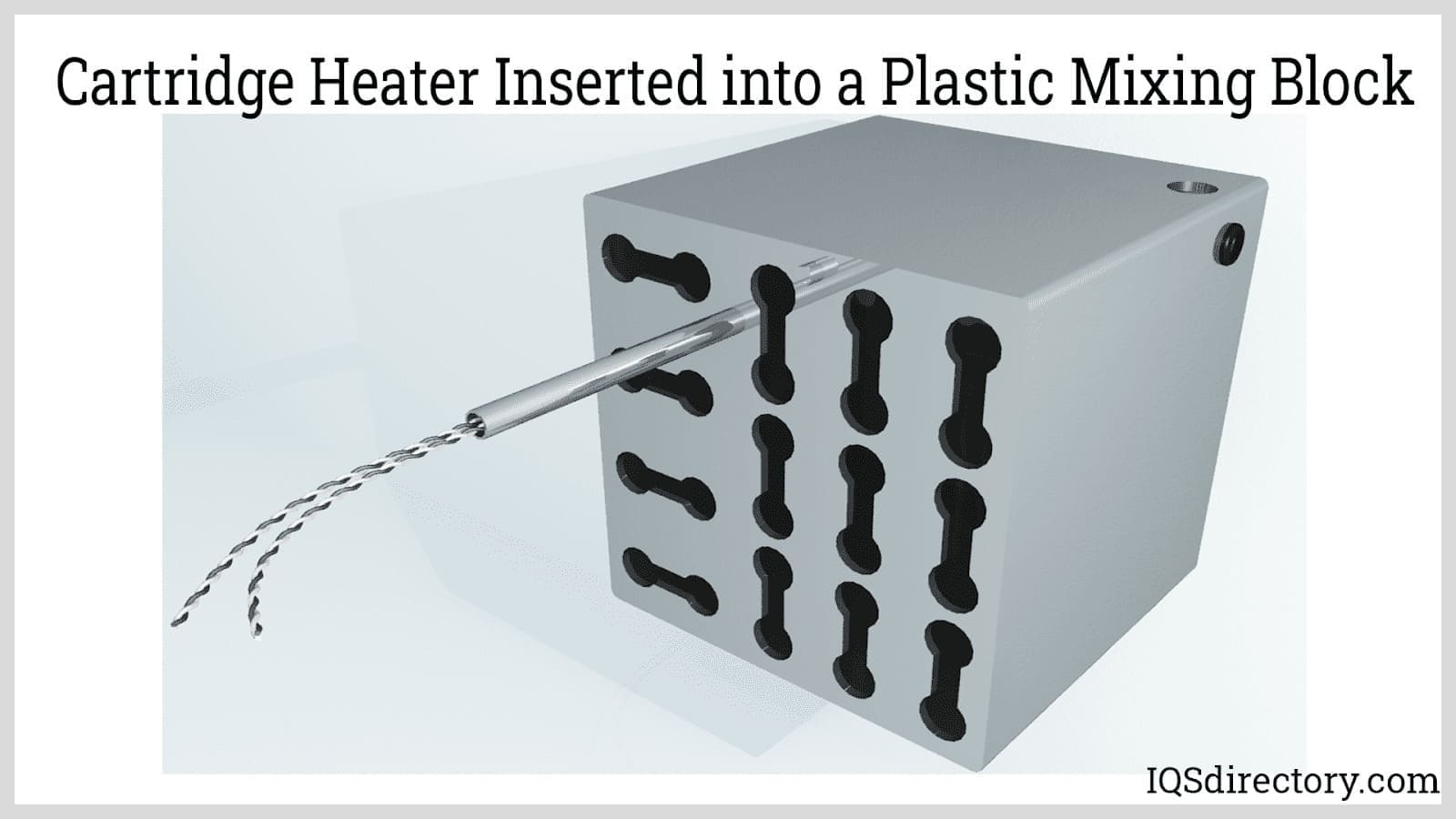

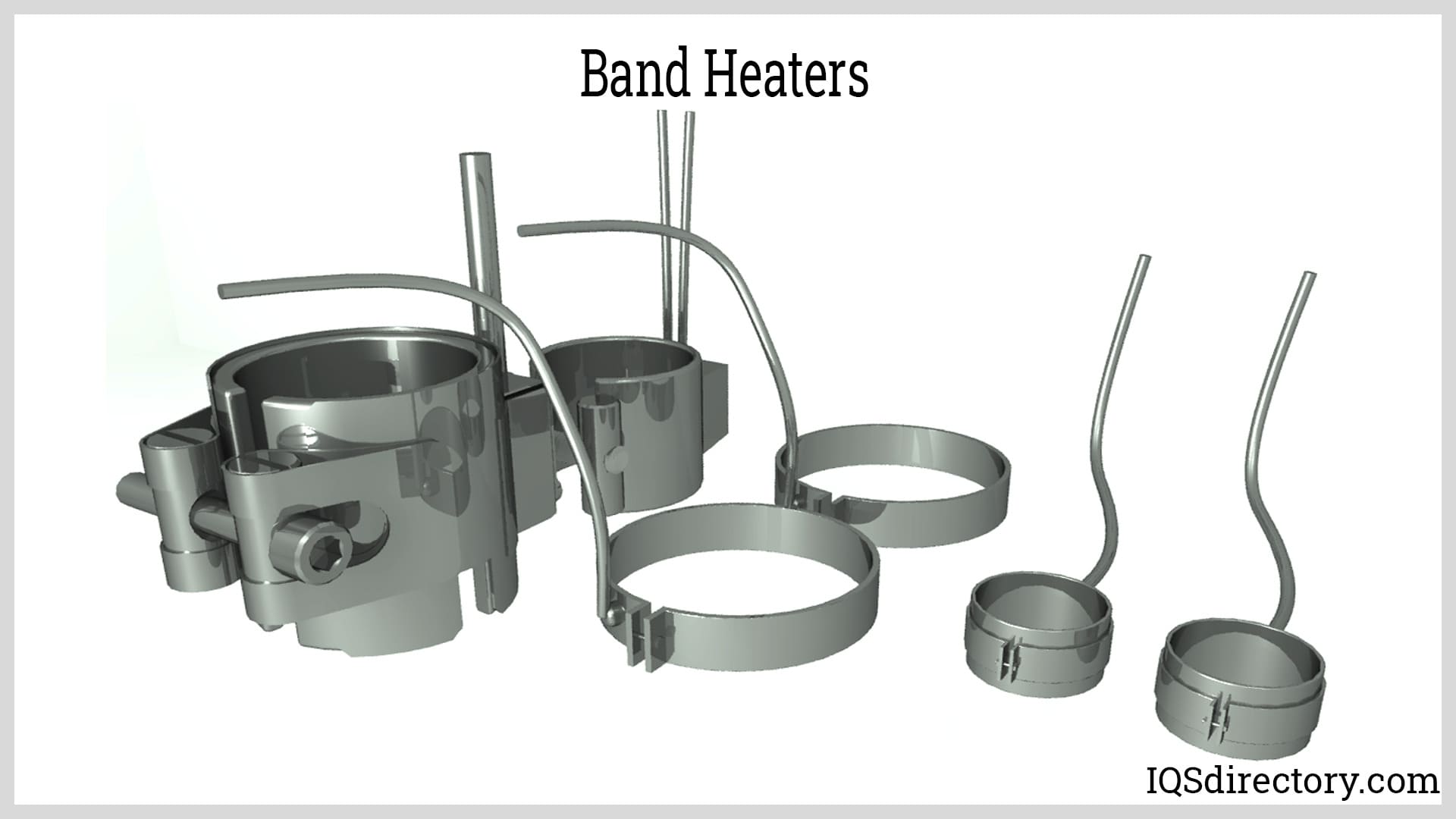

A cartridge heater is a heating element in the shape of a tube that fits into drilled holes and is used in industrial activity. Cartridge heaters are extensively used in the heating process sector because they provide localized and accurate heating. Cartridge heaters are often used to heat a metal block from the inside, and they can be custom produced to a precise watt density based on the application’s requirement. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

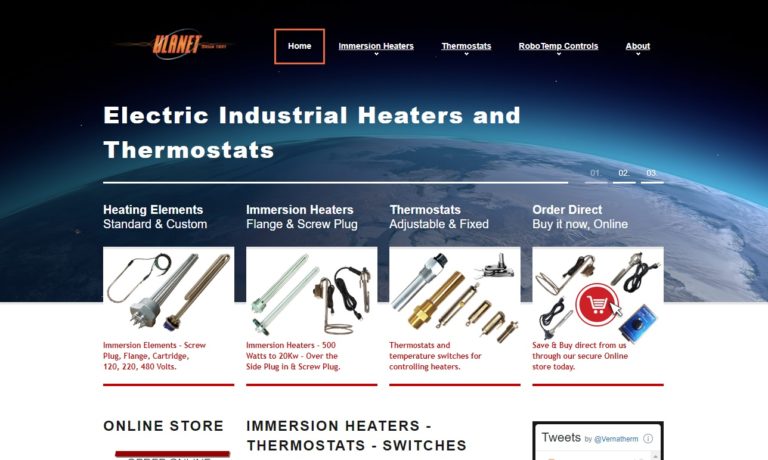

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

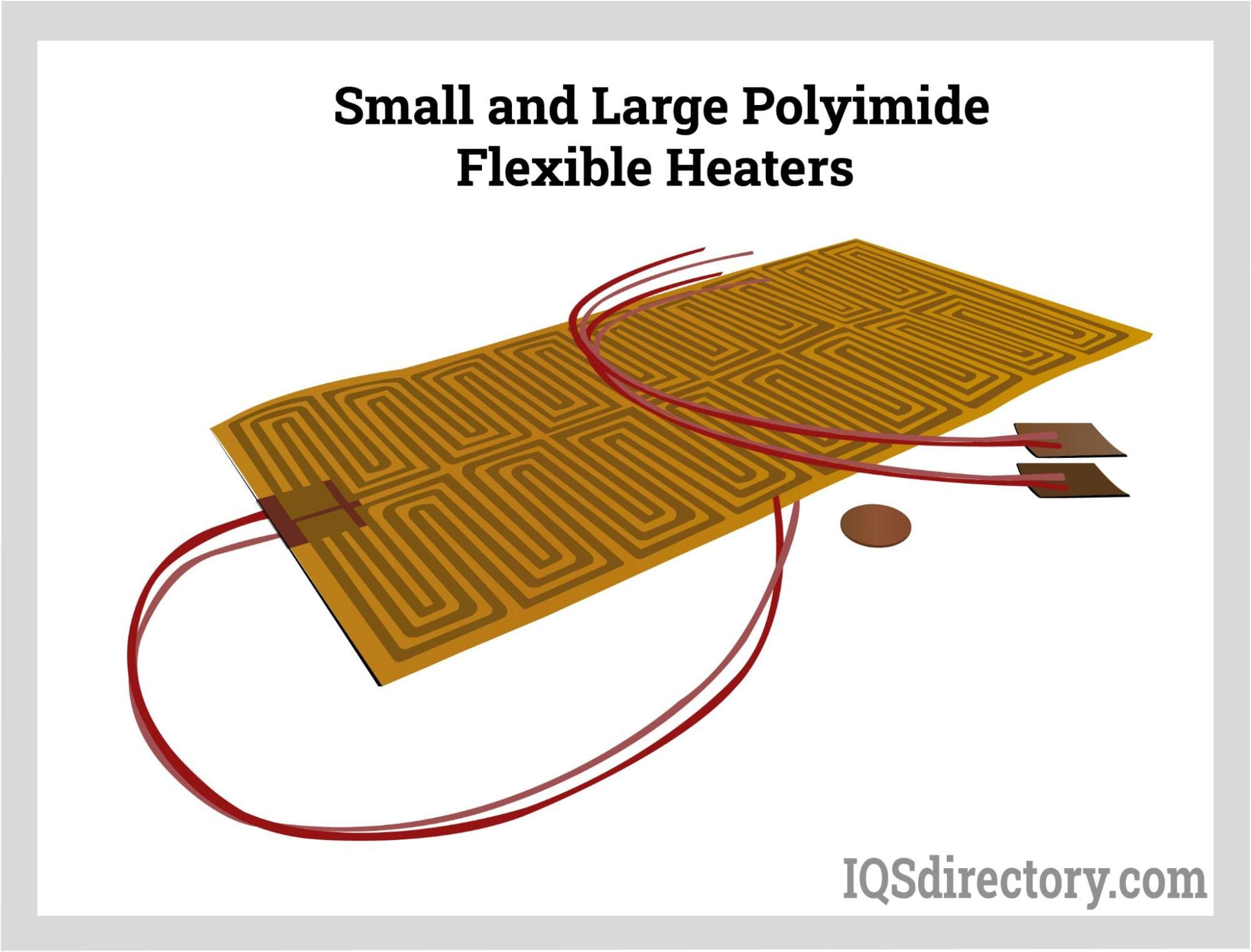

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

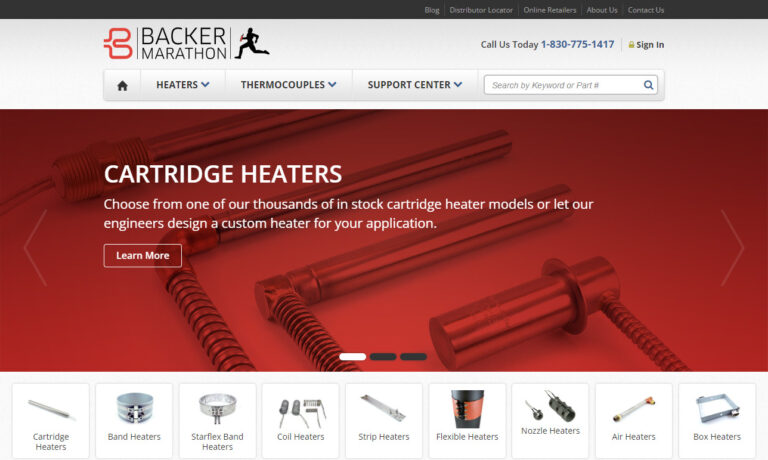

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Cartridge Heater Manufacturers

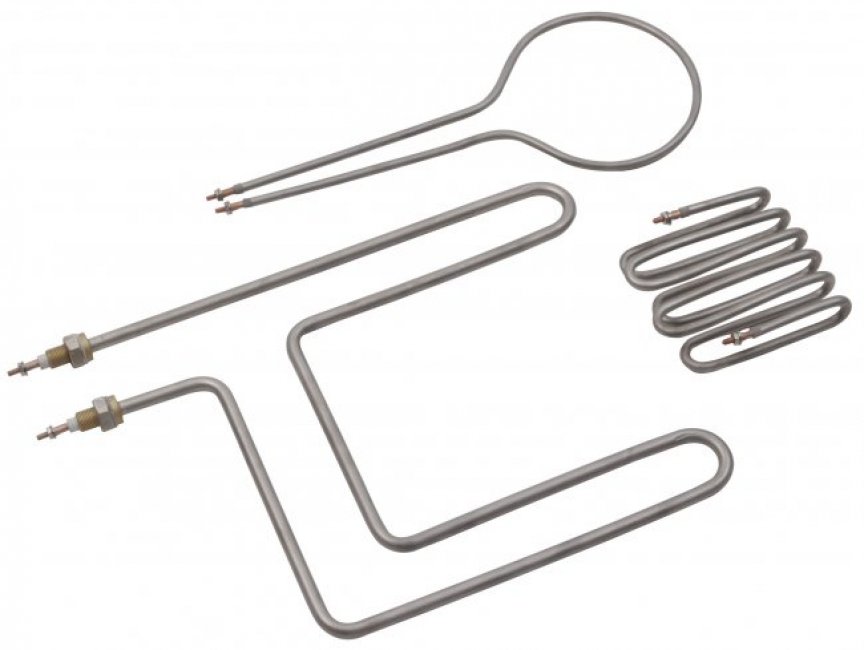

An exterior metal shell, known as a sheath, surrounds the heating element. This shell is usually stainless steel and includes an insulator and a coil of nickel-chromium heater wiring. A standard electrical connection is found on most cartridge heaters; there are, however, different cable designs available, such as right-angle exit, fastening tab, and flange mounting, to mention a few.

Salient Features of Cartridge Heaters

- Corrosion-resistant materials construct corrosion-resistant heaters suited for use in corrosive or chemical environments.

- Explosion-proof heaters are built to withstand explosions while safeguarding the contents within. Some providers include heaters with spark- and flame-resistant housings.

- A grounding wire is included in the heater that may attach the electrical wiring to a common ground to disperse the load in case of a short circuit.

- The heater has an integrated temperature detector that monitors its temperature while operating.

- Cartridge heating elements are UL and CSA certified.

- Cartridge heaters offer temperatures of up to 1562 °F (850 °C) with a maximum voltage of 600V.

- The maximum surface load offered by cartridge heaters is 35 W/cm2.

Materials Used in Cartridge Heaters

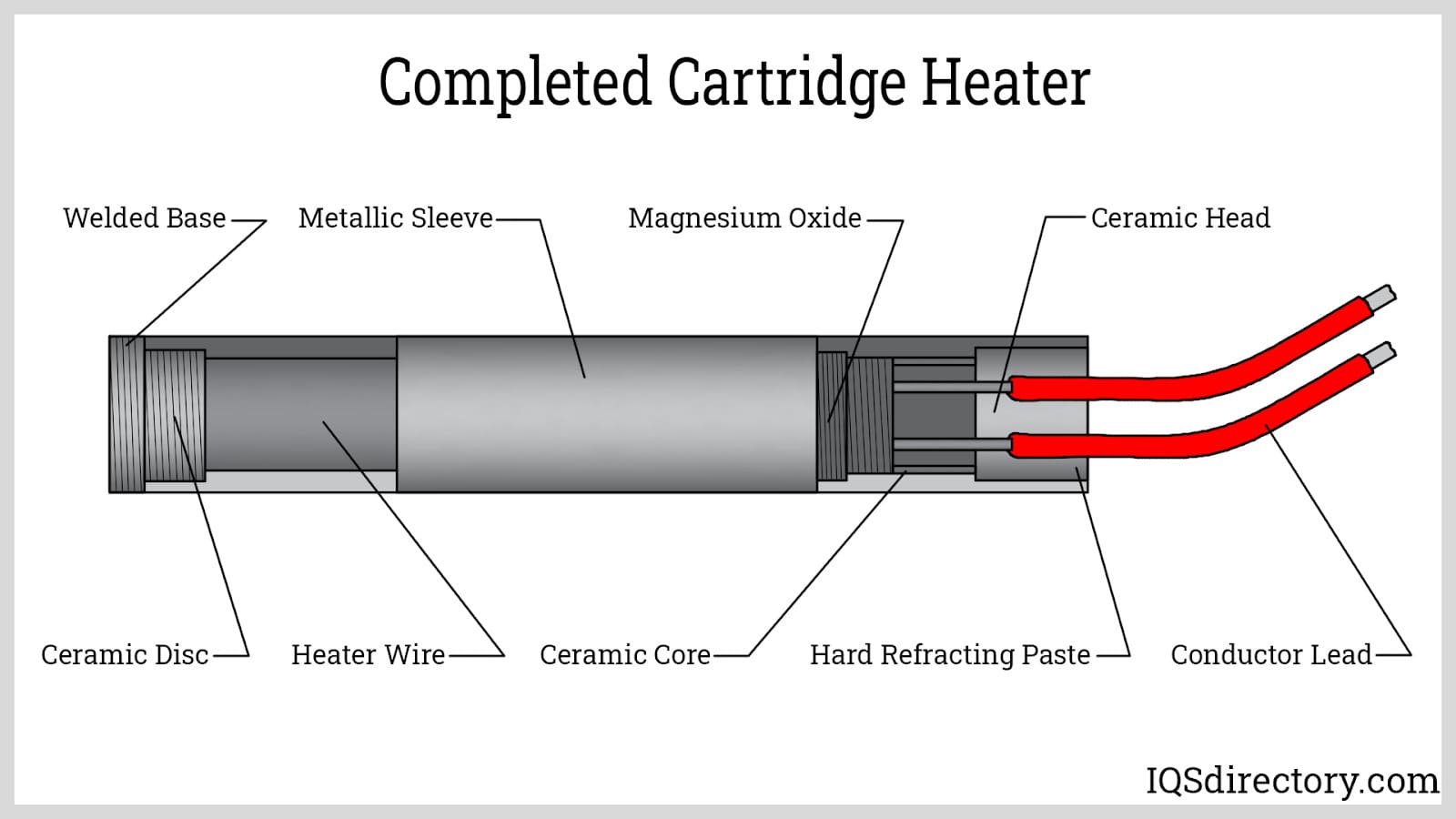

The cartridge heater has four components with different material options available to them.

Jackets, sheaths, or sleeves are employed as a protective exterior covering for heating components. Sleeve materials used in cartridge heaters are often aluminum, stainless steel, nickel alloy, copper, iron, steel, or brass. A few standard options are explained below:

- None: The heater has a bare and exposed heating element that does not contain a sheath or sleeve.

- Stainless Steel: This is used for the sleeve or sheath, a chemically and corrosion-resistant alloy with high-pressure ratings.

- Aluminum: Aluminum is used to make the sleeve or sheath, a ductile, malleable, trivalent, light metal with good electrical and thermal conductivity, oxidation resistance, and high reflectivity.

- Insulation commonly used in a cartridge heater includes fiberglass, ceramic, mica or mineral insulation, magnesium oxide, or fluoropolymer. A few insulation options are explained below:

- Ceramic insulation is made of nonmetallic materials like clay that have been fired at high temperatures to harden them permanently. The majority of ceramics are resistant to heat and chemicals.

- Fiberglass insulation is sturdy, long-lasting, and resistant to various chemicals and harsh temperatures. In industrial usage, fiberglass textiles are commonly utilized.

- Magnesium oxide insulation offers a high melting point (5072 °F [2800 °C]) and temperature resistance (3092 °F [1700 °C] in reducing and 4172 °F [2300 °C] in oxidizing environments).

- The Electrical Connection in a cartridge heater has different termination options, including armor cable leads, screw terminal boxes, metal braided leads, insulated leads, bare leads, plugs, and quick disconnects.

- The Mounting options of a cartridge heater are locating rings, threaded pipe fittings, and mounting flanges.

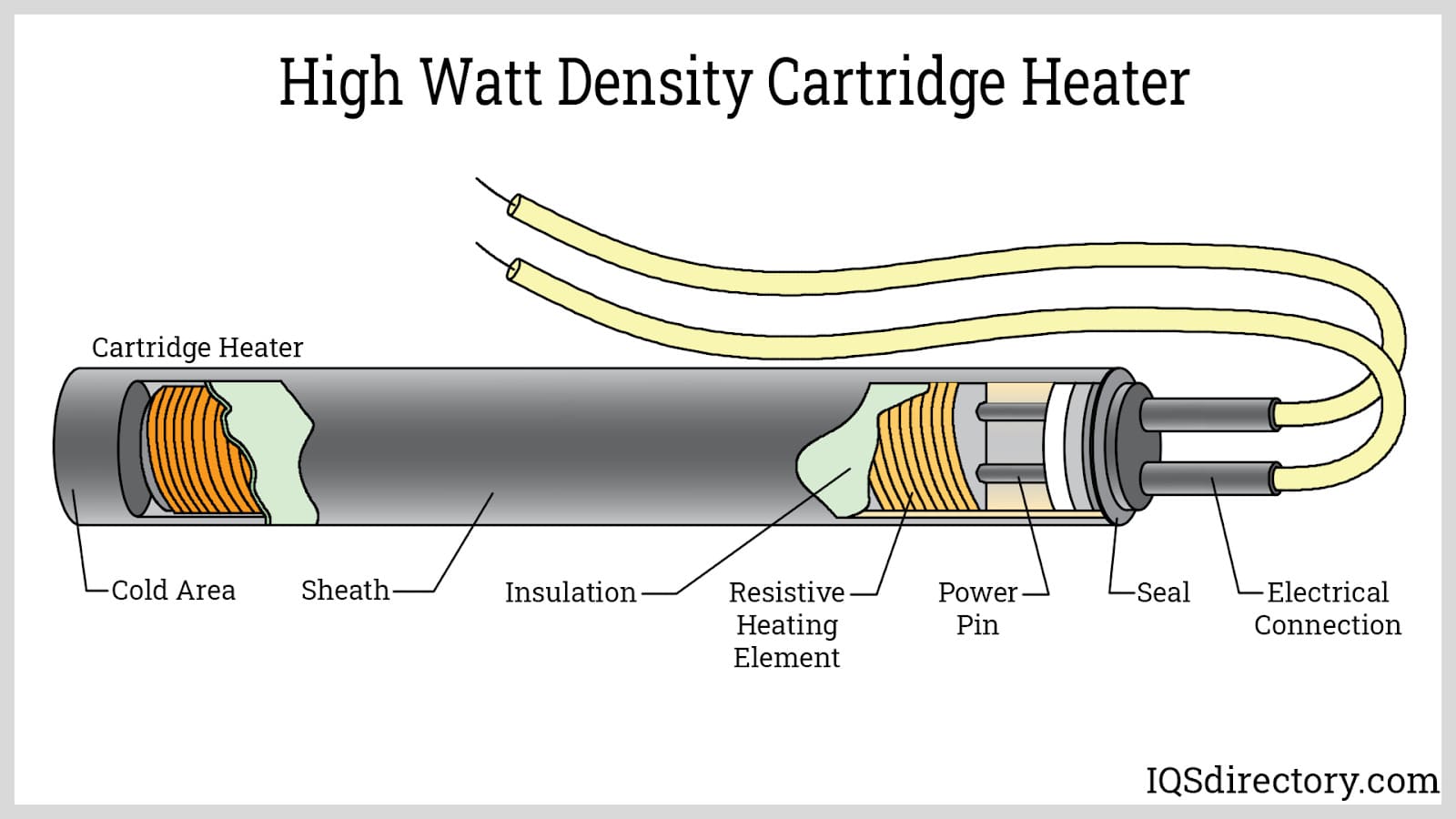

Construction of Cartridge Heaters

The construction process consists of 7 parts:

- Heating Coil: The electrical load or the actual resistance occurs in the heating coil. The most common type used is nichrome.

- Insulation: It is used to prevent the contact of the coil with the sheath; else, a short circuit can occur. Magnesium Oxide (MgO) is typically used in industry.

- Sheath: The sheath is what makes contact with the material or substance that needs to be heated.

- Sealing: A seal is applied to the open end of the cartridge to prevent the coil and insulation used from coming out and contaminants such as dust, air, or moisture from entering.

- Termination: Cartridge heaters are used in various industrial applications to ensure that they can be terminated with the leads coming out straight or at a right angle.

- Lead wire type: Typically, fiberglass is used as the lead wire in high-temperature industrial applications. However, usage may vary depending on the task.

- Watt Density: It is then chosen upon the level of industry work carried out.

How a Cartridge Heater Work?

A cartridge heater works straightforwardly:

- A cartridge heater comprises a resistance coil wound around a ceramic base covered in a metal sheath and surrounded by a dielectric.

- The sheath heats up when powered heat is passed through the coil.

- The heat generated would then be transmitted to the metal element on the inside that needs to be heated.

Applications of Cartridge Heaters

These heaters are intended to heat metal molds, dies, different metal components, and platens in the metalworking industry. Cartridge heaters are also used in the following applications:

- Lamination Processes

- Medical Equipment

- Molding of Plastic

- Molds for Hot Runners

- Wafer Processing for Semiconductors

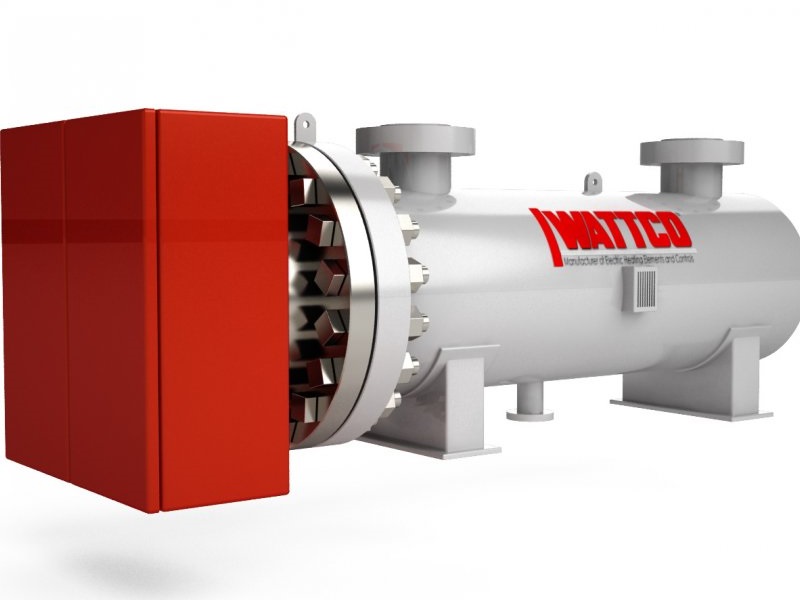

- Heating Liquids and Gasses

Choosing the Correct Cartridge Heater Manufacturer

To ensure you have the most positive outcome when purchasing a cartridge heater from a cartridge heater manufacturer, it is important to compare several companies using our directory of cartridge heater manufacturers. Each cartridge heater company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each cartridge heater business website using our patented website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple cartridge heater businesses with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services