True to its name, a tubular heater is a heater that emits low-level ambient heat. Its main function is to provide enough ambient heat to prevent frost from forming and warm up spaces where regular heating is either impractical or too expensive to operate. Most uses for tubular heaters involve tailored heating. They are made for either radiant heating or contact surface heating and can be shaped into various geometries.Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

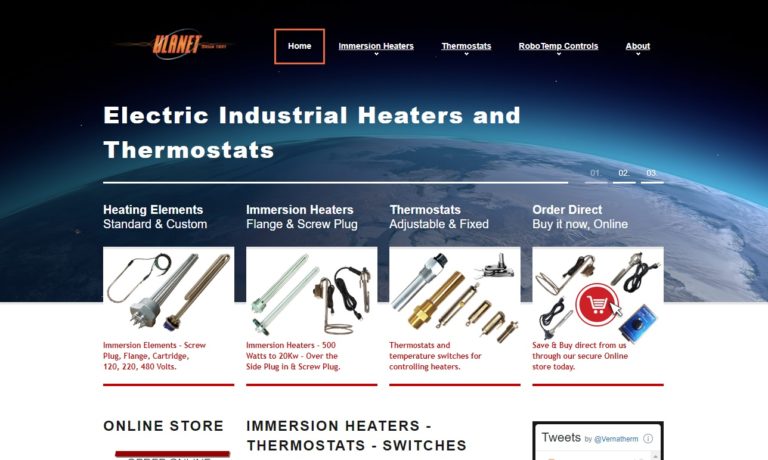

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

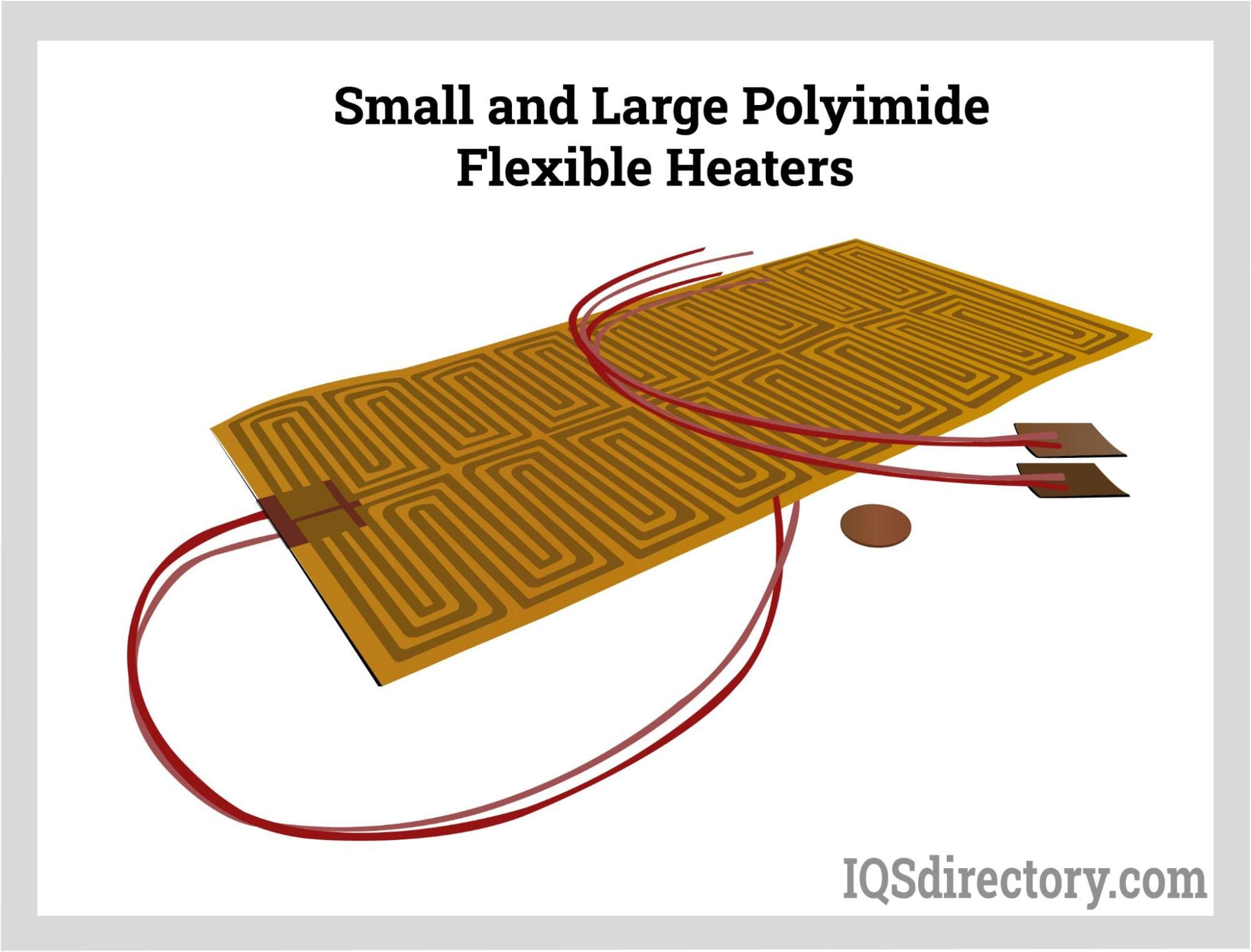

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

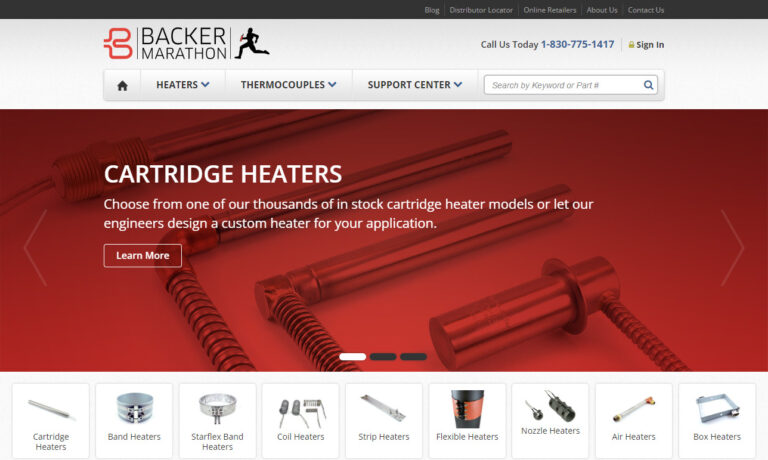

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Tubular Heater Manufacturers

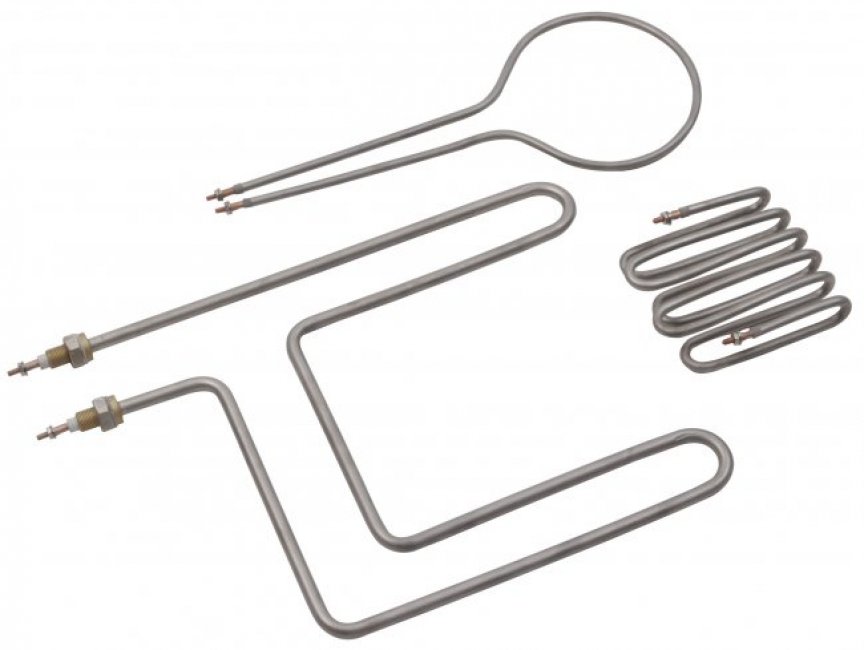

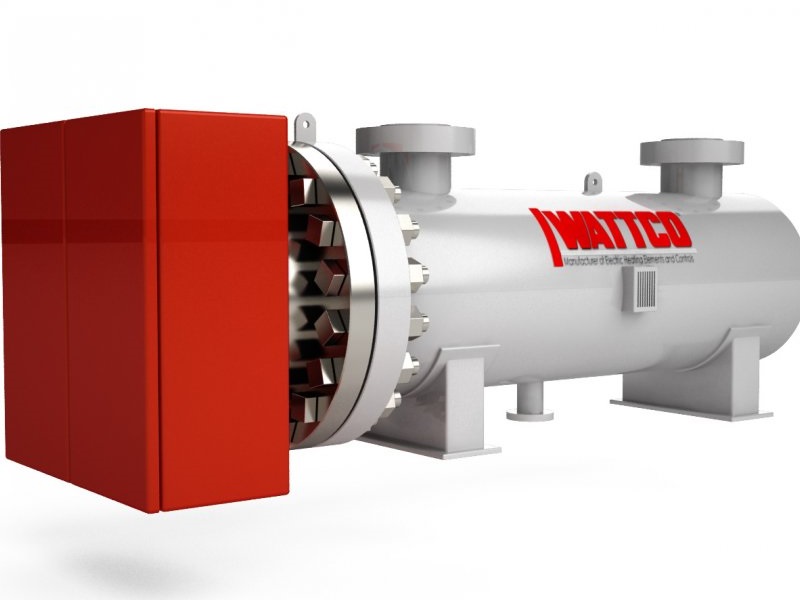

Tubular heaters are frequently submerged in water, oil, or molten metals. Tubular heaters are very energy-efficient because they produce heat inside a liquid or process. Since they may be made of practically any size or shape, tubular heaters are utilized in many industries and process heating applications. Tubular heaters can be used in any area requiring quick, dependable, and affordable heating.

Types of Tubular Heaters

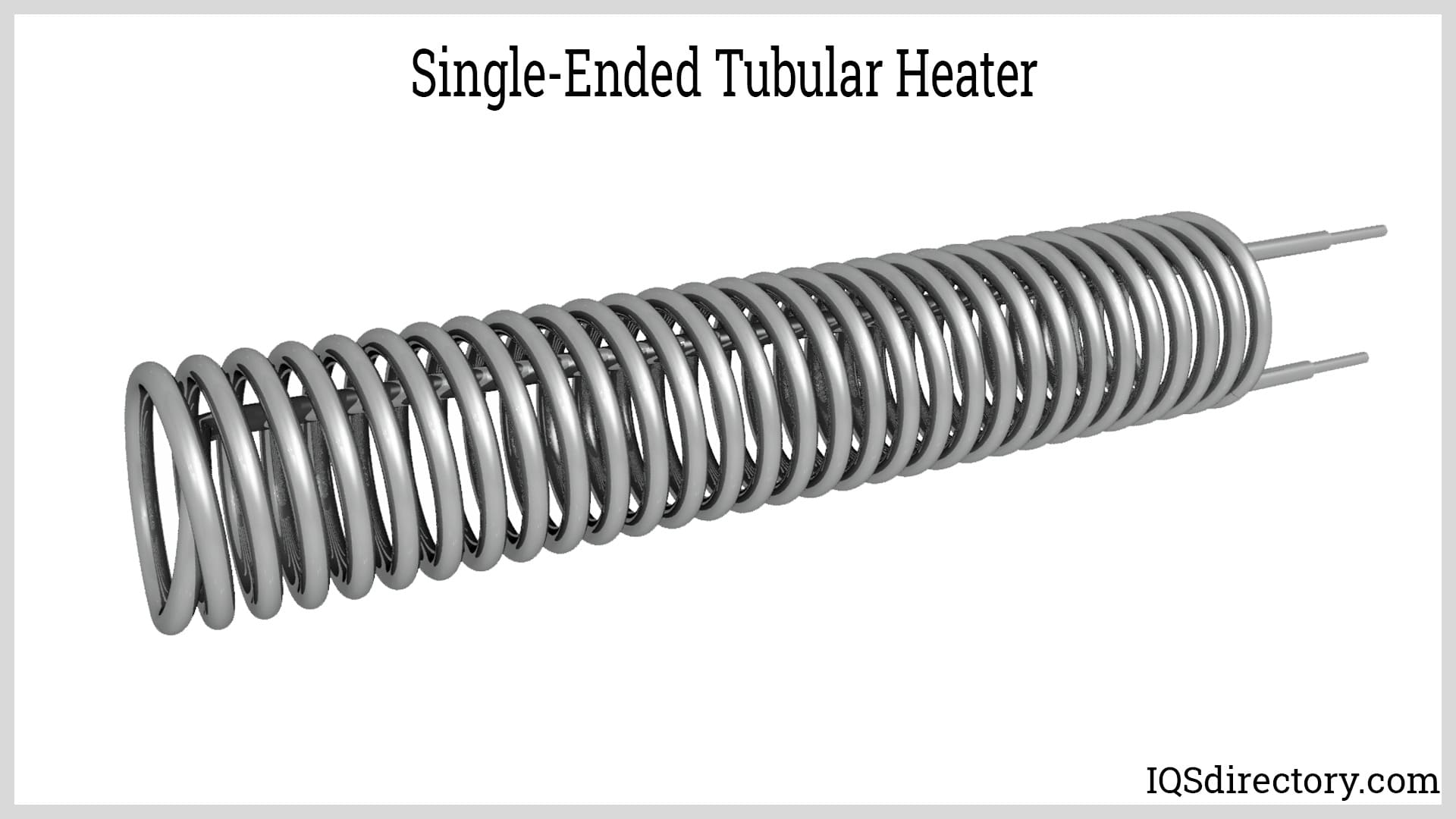

Single-Ended Tubular Heaters

Both terminals are located at one end of the single-ended tubular heater design. The other end has a seal. Flexible lead wires have silicone-impregnated fiberglass oversleeves and are 12 in. (305 mm) crimps linked to the terminal pin.

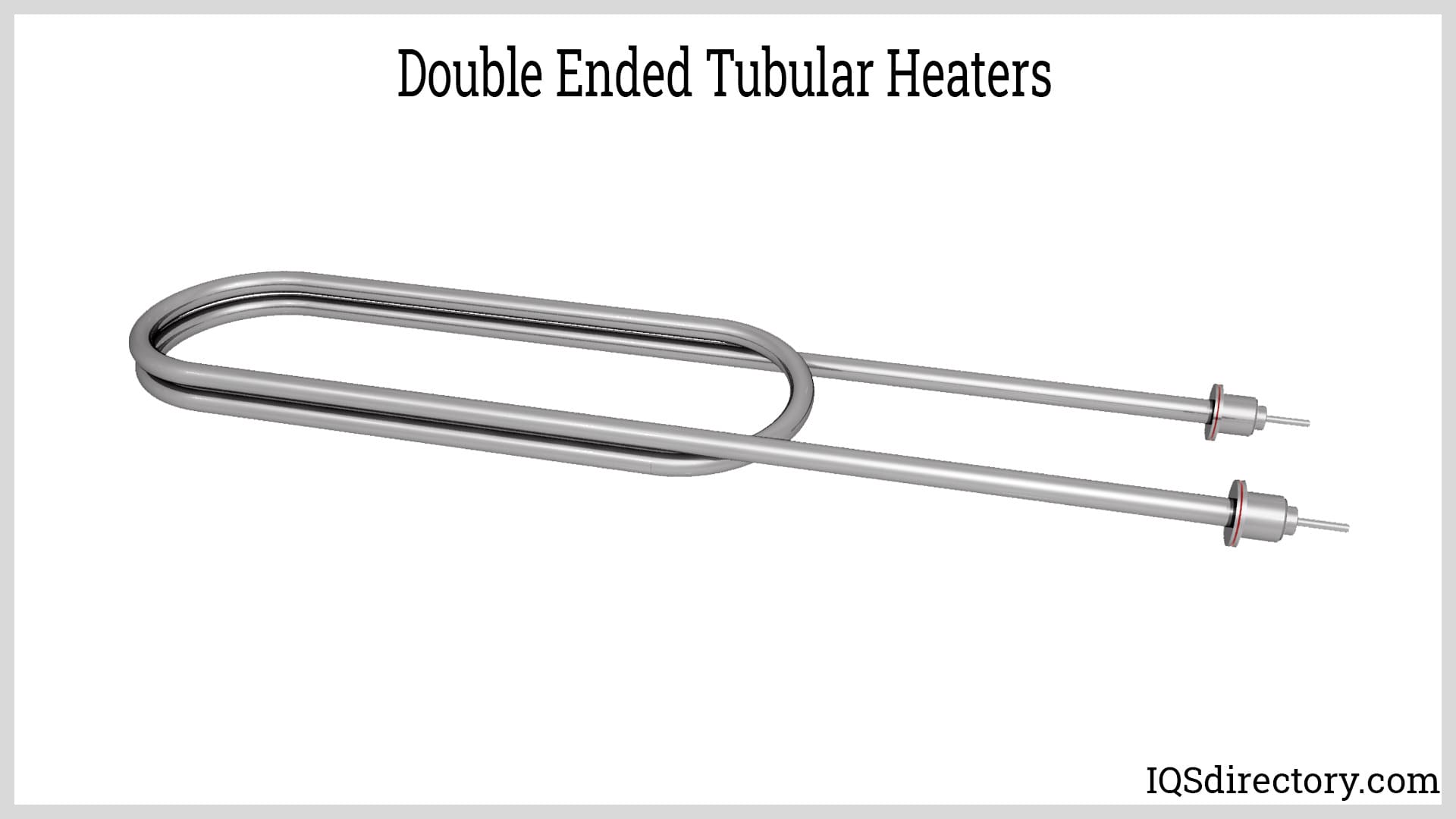

Double-Ended Tubular Heaters

The circular cross-sectional shape of the double-ended tubular heaters lends itself well to bending, particularly when bending is done on the job site. The sheath of a double-ended tubular element may contain several arrangements of thermocouples and resistor coils. They can provide three-phase functionality in a single element or reliably sense the heater's internal temperature.

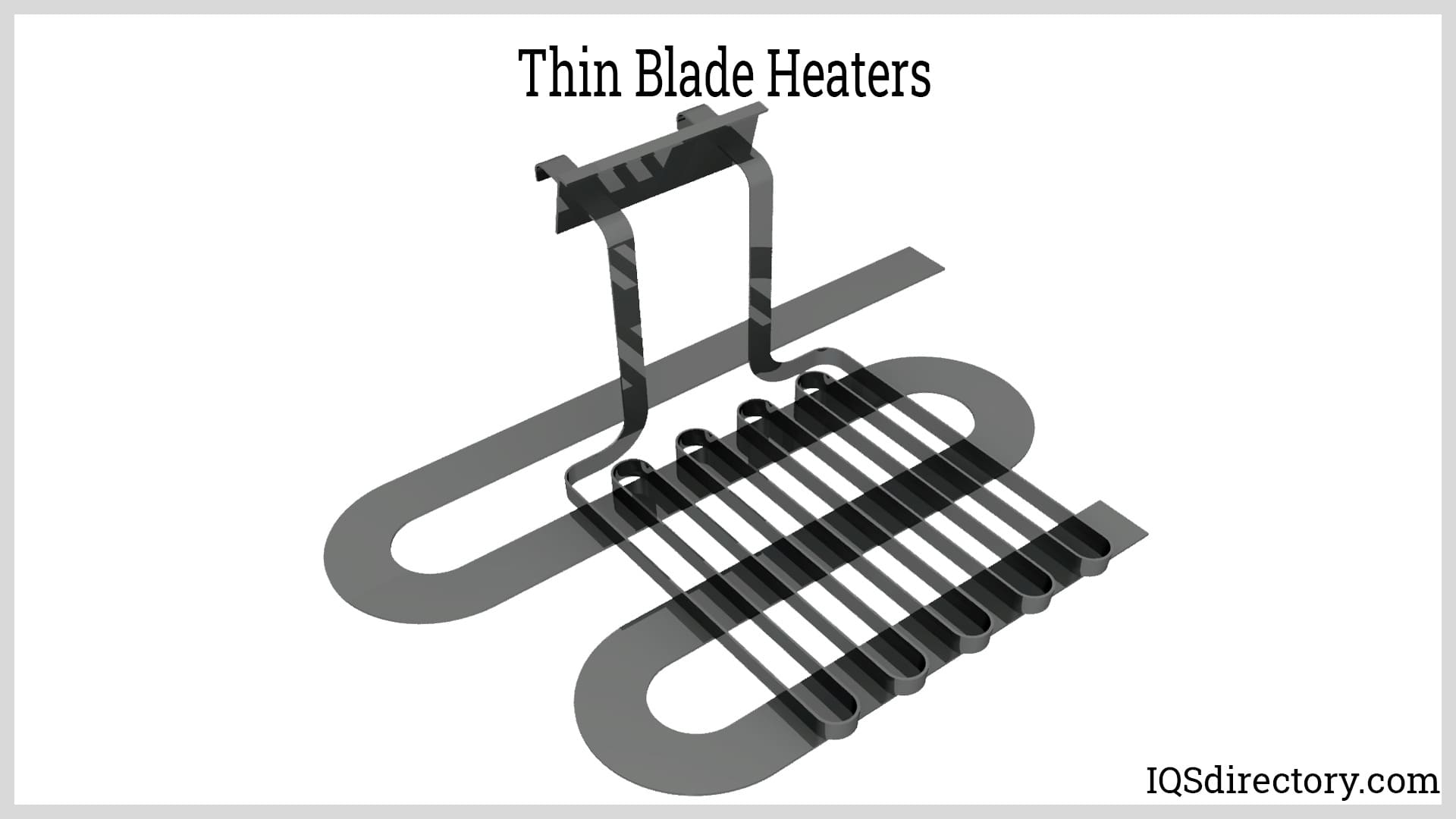

Thin Blade Heaters

Compared to conventional round elements, thin blade heaters offer a larger surface area per unit of length. A thin blade can make equipment with more wattage in a smaller linear space than a typical element. Processed materials may be less prone to deterioration as a result. These are frequently utilized in industrial settings, including degreasing and plating tanks and commercial kitchens.

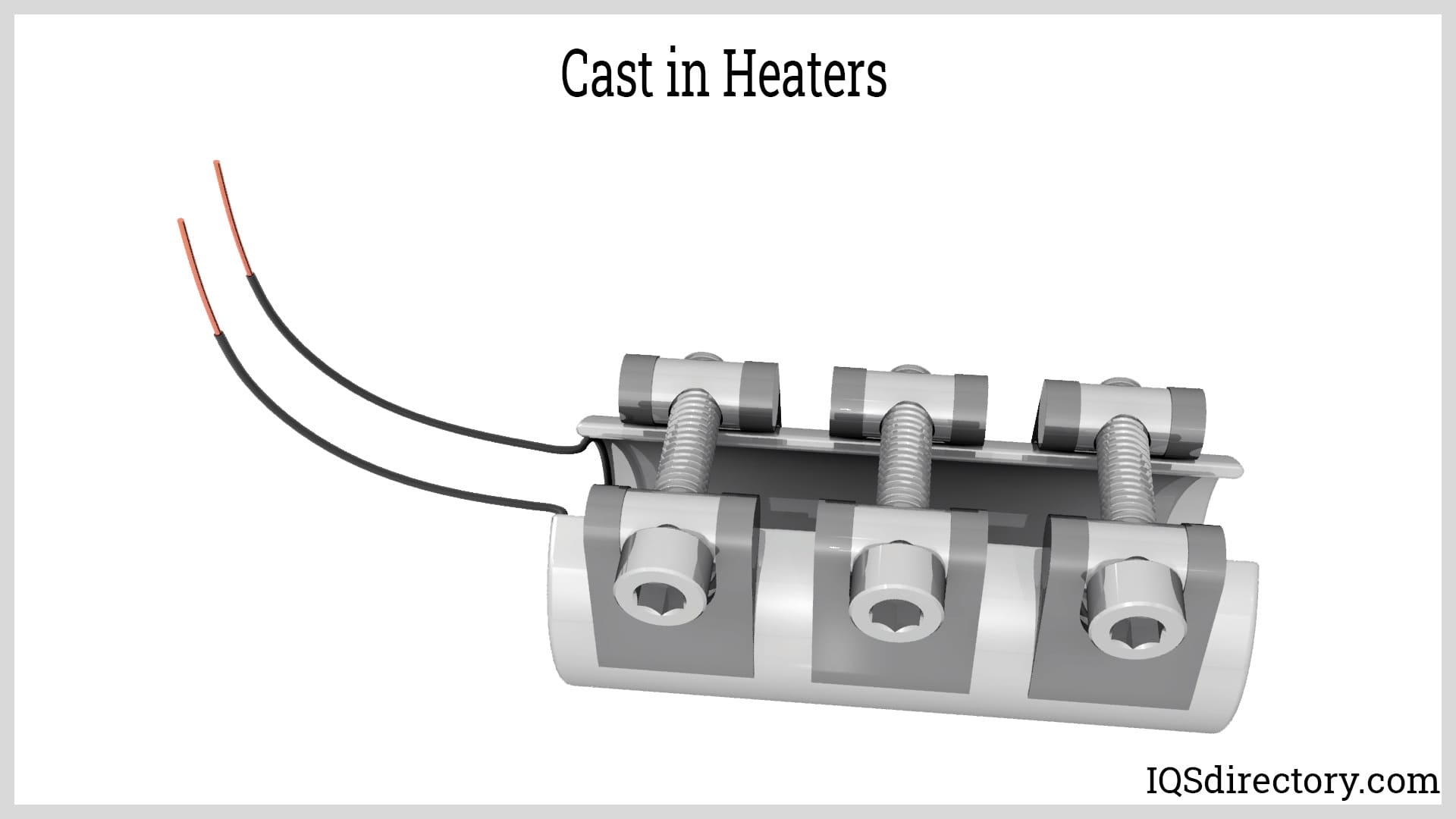

Cast-In Tubular Heaters

Machines in the food industry and pharmaceutical facilities can also use cast-in heaters. They can be coated or not and are used for welding and sealing. Unique aging techniques, uniform heat distribution, highly precise contact surfaces, reaction-fast temperature ranges, and shape stability ensure perfect operating conditions and a long lifespan.

The cast-in heater is utilized for various purposes, including heating plates for presses, extrusion, rubber, and plastics, packing lines, curing, and more. As a result, cast-in heaters are widely used in various industries, including those that deal with plastics, food, pharmaceuticals, semiconductors, metallurgy, petrochemicals, packaging, textiles, and many more.

Applications of Tubular Heaters

- Paint and Enamel Baking Equipment

- Silo Heaters and Hopper - Food, Agriculture, and Plastic

- Animal Incubators for Prenatal Care

- Food Service Equipment

- Ducts

- Epoxy Curing

- Furnaces

- Fusing Laminated Sheets

- Kettles and Tanks

- Ovens - Process, Curing, Food

- Stretch Wrapping Equipment

- Plastic Sheet Bending Equipment

- Spas and Hot Tubs

- Steam Tables

- Welding Preheat Equipment

- Sterilizers and Autoclaves

- Textile and Chemical Dryers

Advantages of Tubular Heaters

Precision

One of the key benefits of tubular heating components is precision. They enable precise heat transfer, improved temperature maintenance, and enhanced temperature management. Temperatures up to 750°C (1,382°F) and watt densities up to 120 WPSI are possible. Moreover, they are adaptable enough to fit almost any application. Additionally manufactured to order, the cold sections shield the terminals. As a result, tubular heating elements can function more effectively and last longer with extreme precision. They are, therefore, affordable and effective.

Compact Size

Tubular heating components' small size has a lot of benefits. Installing them is simply because of their smaller and customized sizes. They are simple to maintain, repair, or replace because they are small. Since these components are simple to take out and put back in, the production process can continue for a short time.

Customization

Tubular heating elements come in various sizes and shapes and are made for maximum durability. The components are set up in the factory to be the ideal size and shape for a given application. Higher performance is possible by bending diameters and radii to fit an application's form, fit, and functions. Tubular heaters are cheaper than coolers of the plate kind.

- Tubular heaters can be applied to systems that operate at higher operating pressures and temperatures.

- Due to the relatively simple nature of pressure testing, tube leaks are more easily found and repaired.

- In a refrigeration system, tubular coolers can also function as a receiver.

- Sacrificial anodes prevent corrosion throughout the entire cooling system.

- Due to the pressure differential, tube coolers may be preferred for lubricating oil.

Disadvantages of Tubular Heaters

- When compared to plate-type coolers, heat transfer efficiency is lower.

- Since a tube cooler needs adequate clearance at one end to remove the tube nest, cleaning and maintenance are challenging.

- Tubular heaters cannot expand the capacity of the tube cooler.

- They entail a larger space requirement than plate coolers.

Choosing the Right Tubular Heater Company

For the most positive outcome when purchasing a tubular heater from a tubular heater company, it is important to compare several tubular heater businesses using our directory of tubular heater suppliers. Each tubular heater supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly contact the supplier for more information or request a quote. Review each tubular heater business website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple tubular heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services