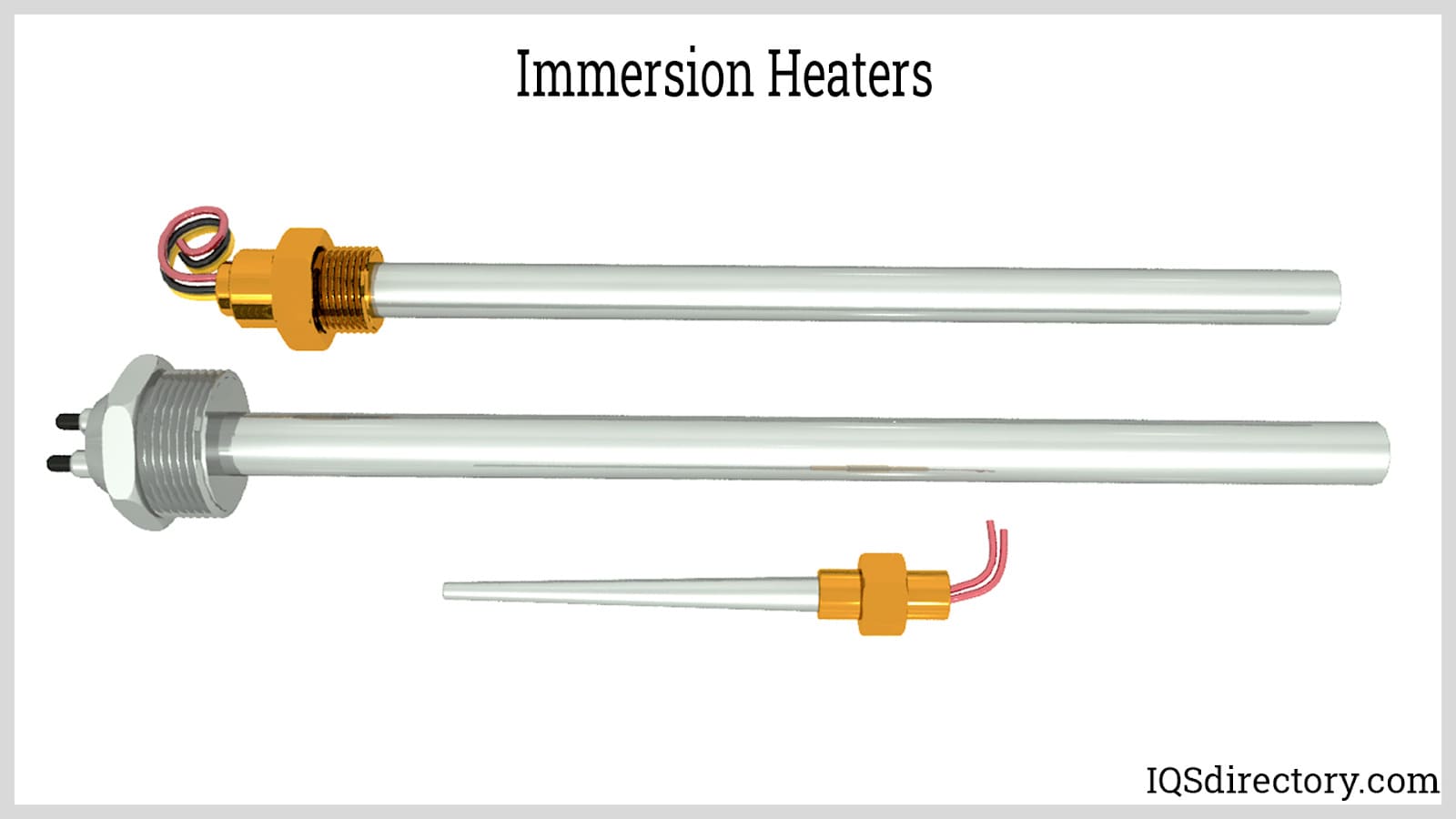

Immersion heaters are used to heat liquids inside tanks or other containers. The installation may be threaded, flanged, or over the side. A resistance heating wire is enclosed in a ceramic jacket, encircled by a sheath to create immersion heaters. The sheath may be constructed from cast iron, copper, stainless steel, PFA-coated steel, Incoloy, or titanium. The element heats the water around it as electricity passes through it. With immersion heaters, water is heated inside the tank directly, rising to the top as it becomes hot. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

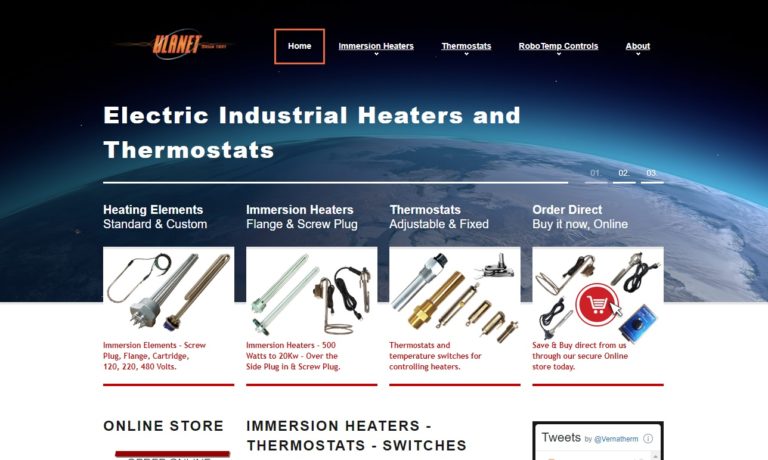

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

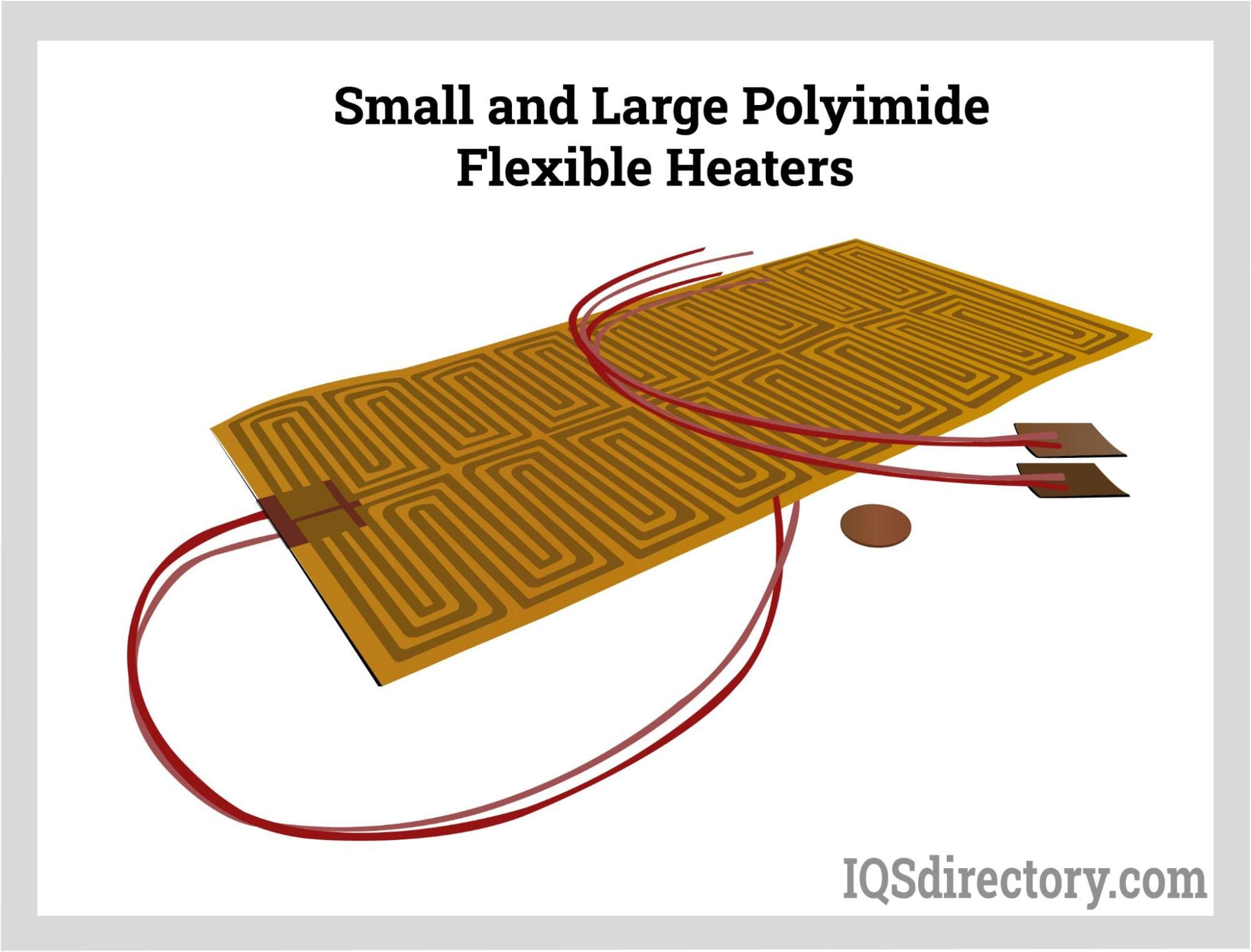

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

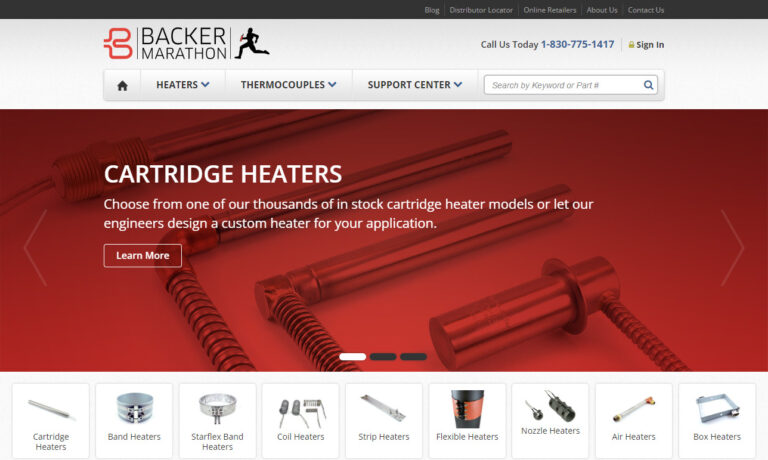

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

Dayco is a manufacturer of a variety of industrial heating and process equipment, including air electric heaters. Direct fired air heaters, indirect fired air heaters, make-up air heaters, recirculating air heaters, as well as custom heaters. Combustion systems and combustion parts and accessories are also available.

DBK designs, develops and manufactures quality standard and custom electric thermal solutions. In addition to a full line of electric heaters, we provide heating elements and heater systems as well as thermoelectric coolers and filtered fan systems. Our expertise gives us the ability to adapt our technologies to find your thermal control solution from immersion heaters to ceramic heaters and more.

More Immersion Heater Manufacturers

Types Of Immersion Heaters

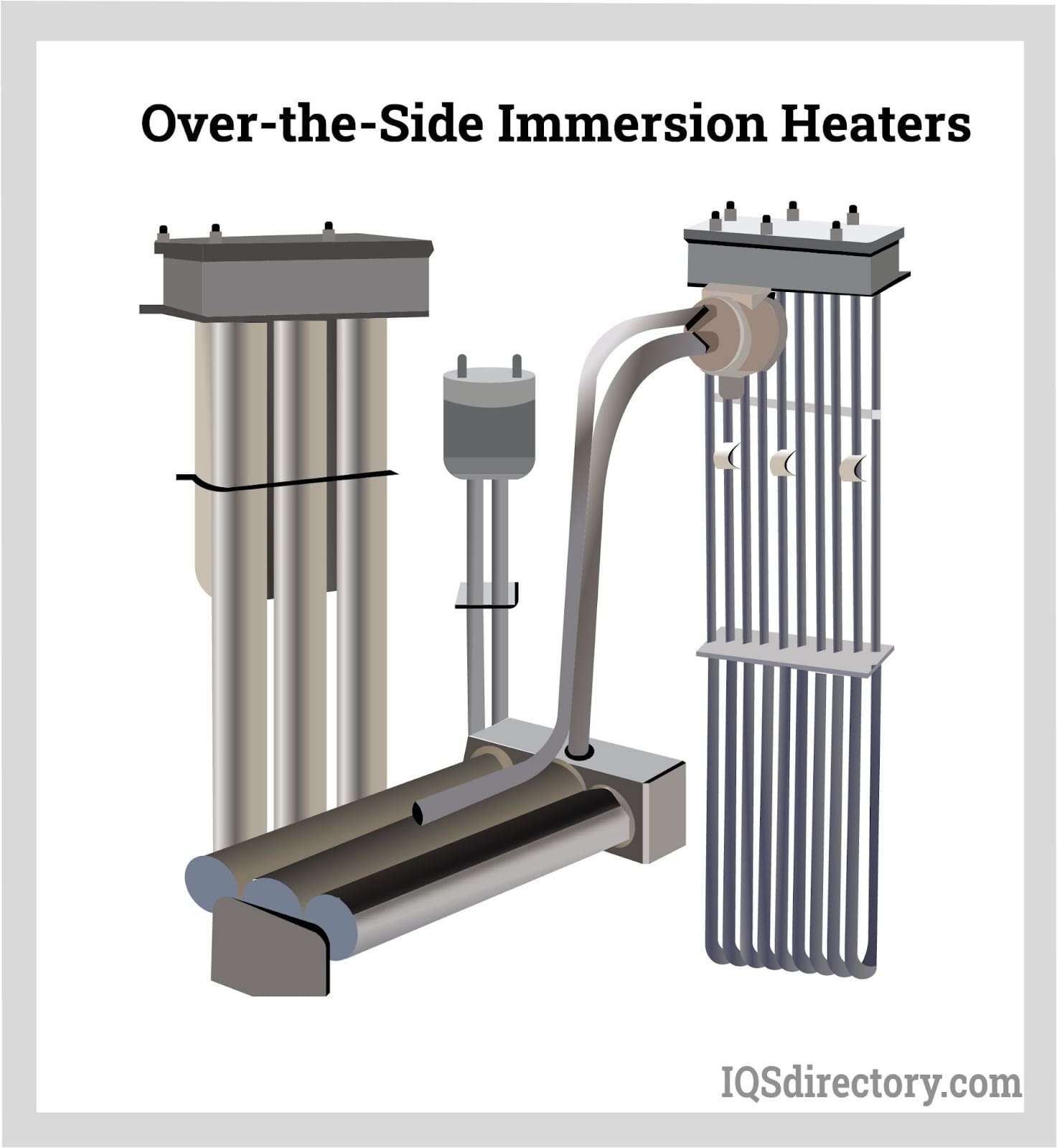

Over-The-Side Immersion Heaters

Over-the-side immersion heaters are mounted either at the side or bottom of the water tank through the top of the vessel. The fluid inside the vessel naturally circulates, allowing for uniform distribution. For power connection, terminal houses or lead wires are offered.

Over-the-side immersion heaters have various heating element types and shapes for various applications. They can heat water, oils, solvent, plating baths, salts, and acids. Over-the-side immersion heaters provide a large working surface inside the tank, are portable, and are simple to remove for cleaning heaters and tanks.

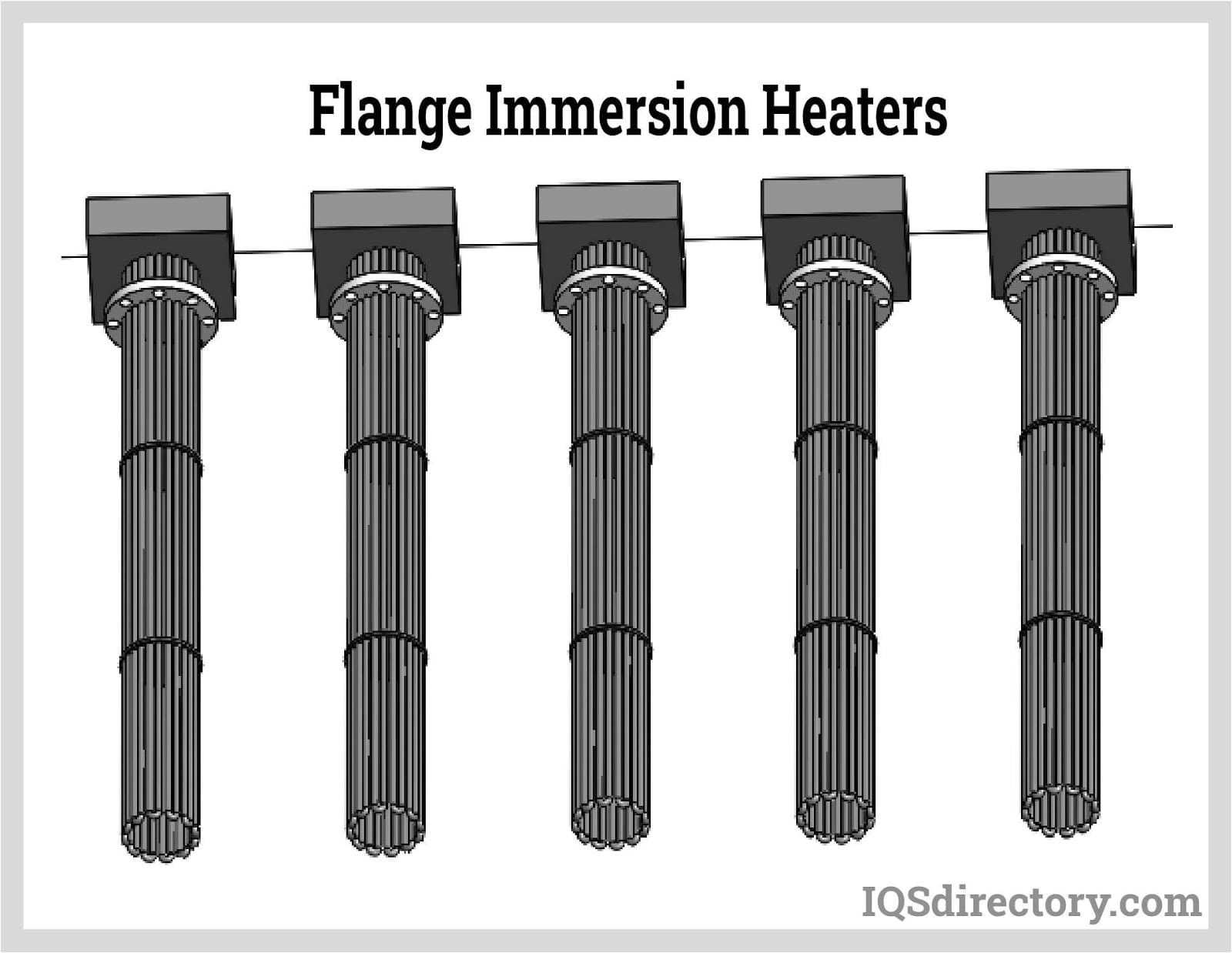

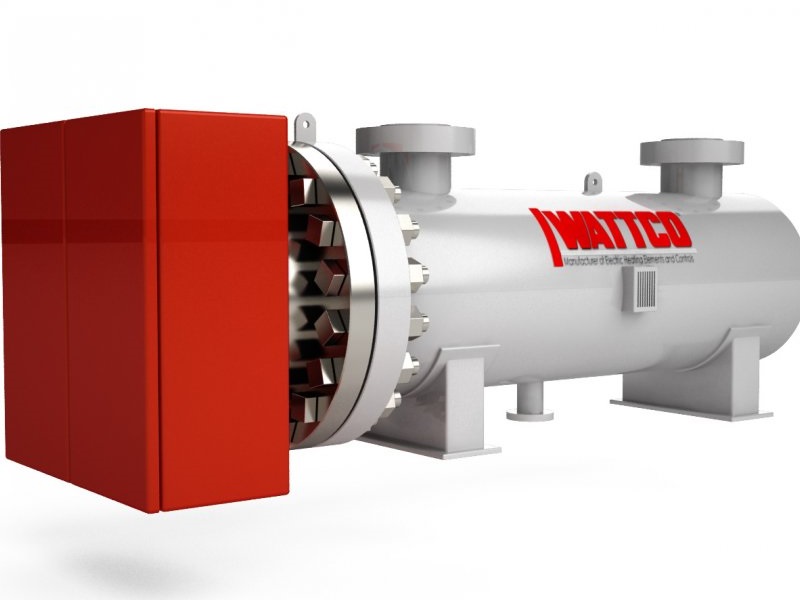

Flanged Immersion Heaters

One of the most common ways to warm liquids is flanged immersion heaters. (such as heat transfer fluid, water, corrosive solutions, and oil). They are simple to install and maintain and are made for usage in tanks and other pressurized vessels. They supply heat for numerous processes. In addition, the direct immersion technique saves energy and is simple to monitor and manage.

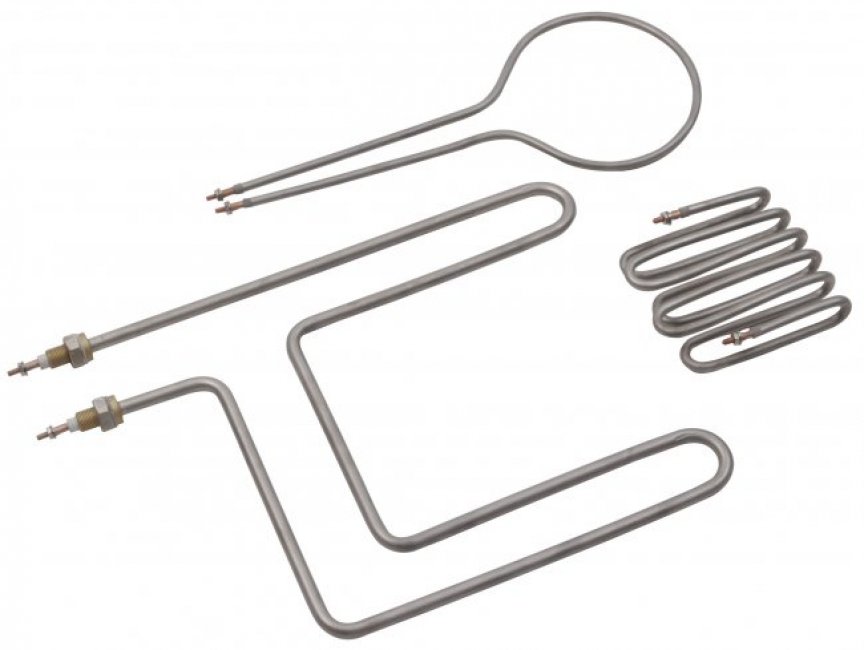

Flanged immersion heaters have wiring boxes for electrical connections and are made of hairpin-bent tubular parts welded or brazed onto a flange. The tank wall or nozzle must have a matching flange bolted to install a flanged heater. These heaters are excellent for many heating applications since they come in various flange diameters, kilowatt ratings, voltages, terminal housings, and sheath materials.

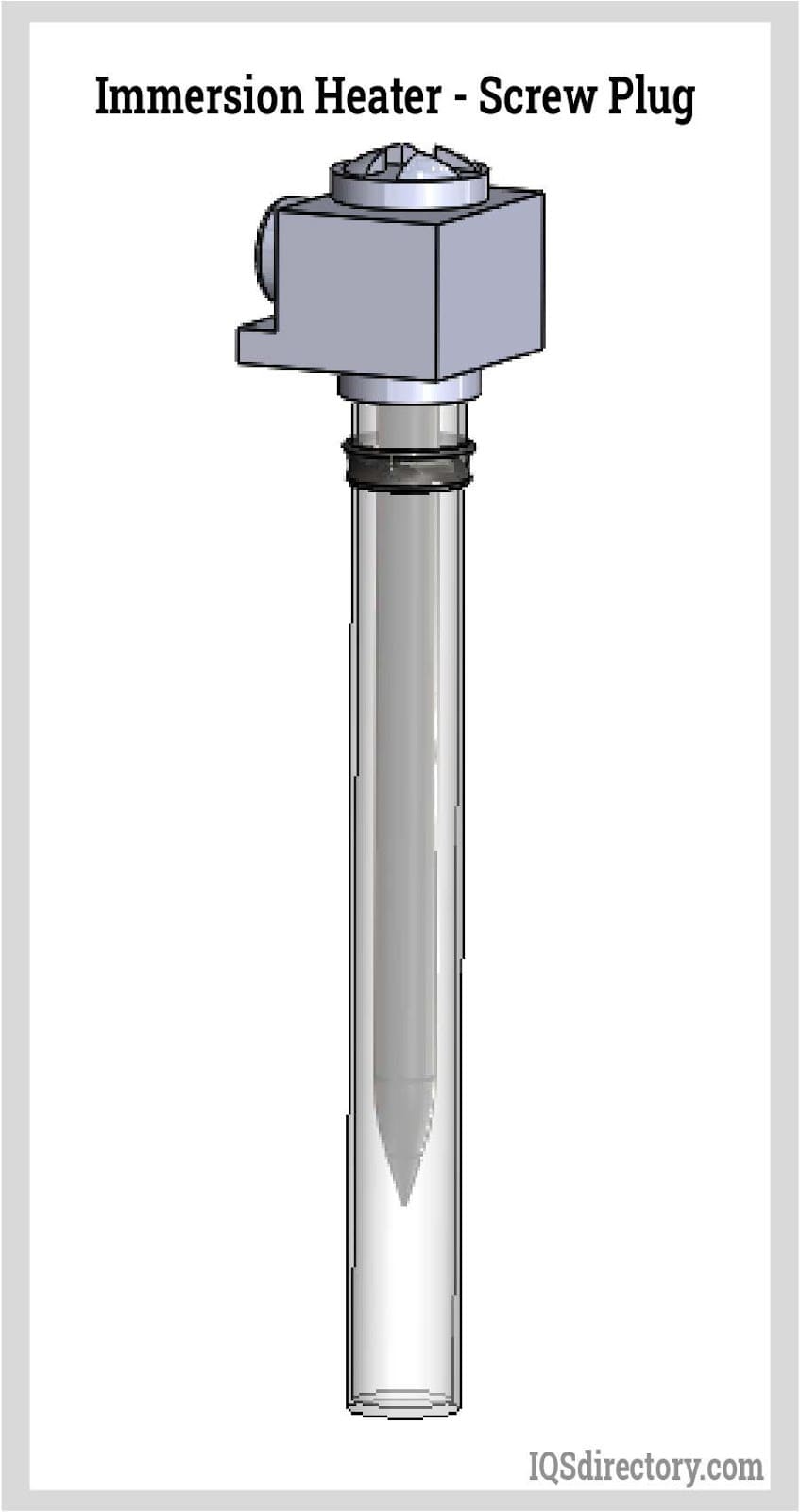

Threaded Or Screw Plug Immersion Heaters

Screw-plug immersion heaters are also used to heat liquids. These heaters are perfect for defrosting frozen pipes and heating process water. The direct immersion technique uses less energy and is suitable for many tasks. Immersion heaters with wiring boxes for electrical connections are made of hairpin-bent tubular parts welded into a screw plug.

Numerous electric heating devices may be added to heat the water, depending on the size of the hot water cylinder. They accomplish this by running a strong electric current through a heating coil-like element, which heats the water in contact with it.

Applications Of Immersion Heaters

Immersion heaters offer a wide range of applications in both domestic and commercial settings. Electric water heaters, air conditioners, instant hot water faucets, steam generators, reactors, and other corrosive or high-temperature usage are examples of household uses. In addition, immersion heaters have a wide range of industrial applications, including

Cement curing

Immersion heaters produce quick, reliable results by accelerating cement curing.

Chemical industry and Laboratories

Electric immersion heaters are essential for maintaining a constant temperature and avoiding freezing detergents, water, oils, and acidic or basic solutions. Immersion heaters are used in labs for sterilization, autoclaves, and pill drying.

Food processing

Ceramic immersion heaters are used to manage moisture that encourages the growth of germs and pathogens that jeopardize the safety of food products. In addition, immersion heaters can disinfect containers and heat liquids so food processing operations can adhere to regulatory rules and quality requirements.

Oil and gas industry

Immersion heaters warm up oil and petrochemical products without altering their structural integrity, allowing them to flow at low temperatures.

Wastewater management

Immersion heaters keep water from freezing in reservoirs and pipes during cold weather to prevent water treatment from failing.

Advantages and Disadvantages Of Immersion Heaters

Immersion heaters are a controllable heating method with low maintenance requirements. They are adaptable to many environments and have advanced heating efficiency.

However, immersion water heaters can’t be turned off automatically. The coils will burn out if used or without water, rendering the appliance ineffective.

Choosing the Proper Immersion Heater Manufacturer

To ensure you have the most positive outcome when purchasing an immersion heater from an immersion heater manufacturer, it is important to compare several companies using our directory of immersion heater manufacturers. Each immersion heater manufacturer has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each immersion heater company website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple immersion heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services